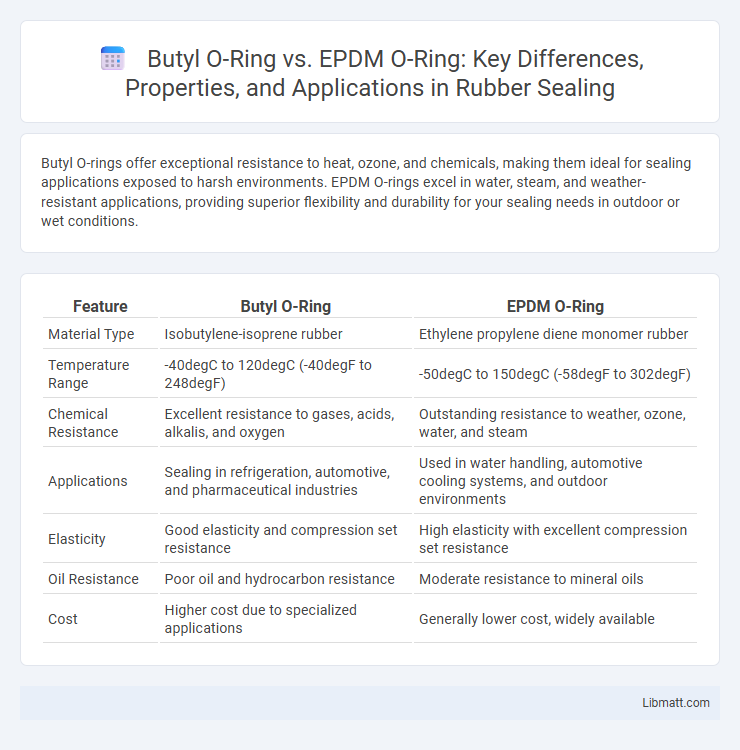

Butyl O-rings offer exceptional resistance to heat, ozone, and chemicals, making them ideal for sealing applications exposed to harsh environments. EPDM O-rings excel in water, steam, and weather-resistant applications, providing superior flexibility and durability for your sealing needs in outdoor or wet conditions.

Table of Comparison

| Feature | Butyl O-Ring | EPDM O-Ring |

|---|---|---|

| Material Type | Isobutylene-isoprene rubber | Ethylene propylene diene monomer rubber |

| Temperature Range | -40degC to 120degC (-40degF to 248degF) | -50degC to 150degC (-58degF to 302degF) |

| Chemical Resistance | Excellent resistance to gases, acids, alkalis, and oxygen | Outstanding resistance to weather, ozone, water, and steam |

| Applications | Sealing in refrigeration, automotive, and pharmaceutical industries | Used in water handling, automotive cooling systems, and outdoor environments |

| Elasticity | Good elasticity and compression set resistance | High elasticity with excellent compression set resistance |

| Oil Resistance | Poor oil and hydrocarbon resistance | Moderate resistance to mineral oils |

| Cost | Higher cost due to specialized applications | Generally lower cost, widely available |

Introduction to O-Rings: Butyl vs EPDM

Butyl O-Rings offer excellent resistance to ozone, weathering, and a wide range of chemicals, making them ideal for applications involving harsh environmental exposure. EPDM O-Rings excel in steam, hot water, and brake fluid resistance, with superior elasticity and temperature tolerance from -40degC to 150degC. Your choice between Butyl and EPDM O-Rings depends on the specific chemical compatibility, temperature range, and durability required for the sealing application.

Chemical Composition and Structure

Butyl O-Rings consist primarily of isobutylene with a small amount of isoprene, giving them excellent resistance to gases and chemicals such as alcohols and ketones due to their saturated polymer structure. EPDM O-Rings are made from ethylene, propylene, and a diene comonomer, which introduces unsaturation that enhances flexibility and resistance to heat, ozone, and polar solvents like acids and alkalis. Your choice between these materials depends on the specific chemical environment and durability requirements, as Butyl excels in hydrocarbon resistance while EPDM performs better with polar chemicals and weathering.

Key Physical Properties Comparison

Butyl O-rings offer exceptional resistance to gas permeability and excellent flexibility at low temperatures, making them ideal for sealing applications in automotive and pharmaceutical industries. EPDM O-rings excel in resistance to heat, ozone, and weathering, with superior performance against polar solvents and steam, commonly used in water and chemical processing. Choosing between Butyl and EPDM O-rings depends on your specific environment, emphasizing gas barrier properties for Butyl or chemical resistance and durability for EPDM.

Temperature Resistance: Butyl vs EPDM

Butyl O-rings exhibit excellent temperature resistance, functioning effectively in a range from -40degC to 120degC, making them suitable for applications involving moderate heat exposure. EPDM O-rings outperform Butyl in high-temperature environments, withstanding temperatures from -50degC up to 150degC, ideal for automotive and industrial seals exposed to steam and hot water. The superior thermal stability of EPDM ensures longer durability and resistance to heat aging compared to Butyl.

Chemical Compatibility and Resistance

Butyl O-rings offer excellent chemical resistance to polar solvents, ketones, and acids, making them ideal for applications involving harsh chemicals and weather exposure. EPDM O-rings excel in resisting heat, ozone, and steam, showing superior performance against alkalis, acids, and hydraulic fluids but poor compatibility with petroleum-based oils. Selecting between Butyl and EPDM depends on the specific chemical environment, with Butyl preferred for resistance to polar solvents and EPDM favored for high-temperature and steam applications.

Applications and Industry Use Cases

Butyl O-rings excel in applications requiring excellent resistance to heat, ozone, and weathering, making them ideal for automotive fuel systems, HVAC equipment, and pharmaceutical sealing solutions. EPDM O-rings offer superior performance in water, steam, and polar solvents, commonly used in water treatment, food processing, and electrical insulation industries. Your choice between butyl and EPDM O-rings depends on the specific chemical compatibility and environmental conditions of your industrial application.

Durability and Lifespan

Butyl O-Rings offer exceptional resistance to ozone, weathering, and aging, resulting in a longer lifespan in harsh environmental conditions compared to EPDM O-Rings. EPDM O-Rings provide excellent resistance to heat, water, and steam but tend to wear faster when exposed to oils or hydrocarbons, reducing their overall durability. Selecting Butyl O-Rings enhances durability and lifespan in outdoor or industrial applications, while EPDM is ideal for water-related environments with moderate durability demands.

Cost Analysis: Butyl O-Ring vs EPDM O-Ring

Butyl O-rings typically exhibit higher cost due to their superior resistance to ozone and extreme temperatures, making them ideal for specialized industrial applications. EPDM O-rings, on the other hand, offer a more budget-friendly option with excellent resistance to weathering, water, and steam, suitable for general-purpose sealing tasks. Your choice between Butyl and EPDM O-rings should weigh the initial investment against the longevity and performance requirements of your specific application.

Installation and Maintenance Considerations

Butyl O-rings offer excellent resistance to weathering and ozone, making them ideal for outdoor installations, while EPDM O-rings provide superior chemical resistance, especially against acids and steam, which suits industrial environments. Installation of butyl O-rings requires caution to avoid stretching that could compromise their elasticity, whereas EPDM O-rings demand careful handling to prevent abrasion during fitting that might lead to surface damage. For maintenance, your choice impacts longevity; butyl O-rings need regular inspection for cracking in high UV exposure, while EPDM O-rings require monitoring for degradation when exposed to oils or solvents.

How to Choose the Right O-Ring Material

Choosing the right O-ring material depends on your application's specific requirements, including temperature ranges, chemical exposure, and mechanical stress. Butyl O-rings offer excellent resistance to ozone, weathering, and a wide range of chemicals, making them ideal for sealing in harsh environments, while EPDM O-rings provide superior performance against water, steam, and polar solvents, with outstanding flexibility at low temperatures. Evaluate your system's operating conditions to select the O-ring material that ensures optimal sealing durability and reliability.

Butyl O-Ring vs EPDM O-Ring Infographic

libmatt.com

libmatt.com