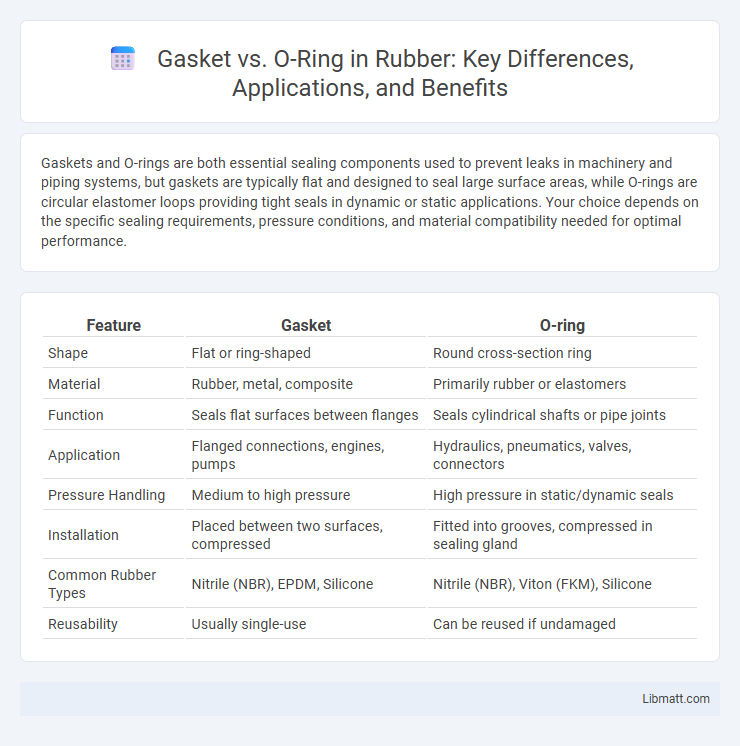

Gaskets and O-rings are both essential sealing components used to prevent leaks in machinery and piping systems, but gaskets are typically flat and designed to seal large surface areas, while O-rings are circular elastomer loops providing tight seals in dynamic or static applications. Your choice depends on the specific sealing requirements, pressure conditions, and material compatibility needed for optimal performance.

Table of Comparison

| Feature | Gasket | O-ring |

|---|---|---|

| Shape | Flat or ring-shaped | Round cross-section ring |

| Material | Rubber, metal, composite | Primarily rubber or elastomers |

| Function | Seals flat surfaces between flanges | Seals cylindrical shafts or pipe joints |

| Application | Flanged connections, engines, pumps | Hydraulics, pneumatics, valves, connectors |

| Pressure Handling | Medium to high pressure | High pressure in static/dynamic seals |

| Installation | Placed between two surfaces, compressed | Fitted into grooves, compressed in sealing gland |

| Common Rubber Types | Nitrile (NBR), EPDM, Silicone | Nitrile (NBR), Viton (FKM), Silicone |

| Reusability | Usually single-use | Can be reused if undamaged |

Introduction to Gaskets and O-Rings

Gaskets and O-rings serve as essential sealing components in mechanical systems to prevent leaks and maintain pressure integrity. Gaskets typically consist of flat, flexible materials designed to fill the space between two mating surfaces, while O-rings are circular elastomeric rings used to create a seal in dynamic or static applications. Both components vary in material composition, including rubber, silicone, and metal, selected based on temperature, pressure, and chemical compatibility requirements.

What is a Gasket?

A gasket is a mechanical seal that fills the space between two or more mating surfaces to prevent leakage of fluids or gases under compression. Typically made from materials such as rubber, silicone, metal, or cork, gaskets are designed to withstand high pressure, temperature, and chemical exposure in various industrial applications. Your choice of gasket depends on factors like operating environment, pressure requirements, and compatibility with the substances being sealed.

What is an O-Ring?

An O-ring is a circular sealing component typically made from elastomeric materials like rubber, designed to fit into a groove and compress between two or more parts to create a tight seal. Its primary function is to prevent the passage of liquids or gases in static or dynamic applications, making it essential in hydraulic systems, engines, and pneumatic devices. The O-ring's simple geometry and reliable sealing capability make it distinct from gaskets, which often have more complex shapes tailored for flange or surface sealing.

Key Material Differences

Gaskets are typically made from materials like rubber, silicone, metal, cork, or asbestos, designed to create a static seal between two surfaces, often accommodating irregularities. O-rings are primarily manufactured from elastomers such as nitrile, fluorocarbon (Viton), or silicone, providing a flexible, dynamic seal capable of withstanding high pressure within cylindrical grooves. The key material difference lies in gaskets' versatility in composition and shape for sealing flat surfaces, whereas O-rings rely on elastic materials optimized for robust, repetitive sealing under compression.

Shape and Design Comparison

Gaskets typically feature flat, sheet-like designs that provide a broad sealing surface for flanges and static joints, while O-rings are circular, torus-shaped elastomers designed to fit into grooves and create a seal under compression. The flat geometry of gaskets allows them to accommodate irregular surface contours and distribute pressure evenly across the joint, whereas the round cross-section of O-rings ensures uniform sealing force in dynamic or static sealing applications. Understanding the distinct shape and design differences helps you select the optimal sealing component for your specific mechanical assembly or fluid system.

Sealing Mechanisms Explained

Gaskets create seals by filling the space between two mating surfaces, compressing under pressure to prevent fluid or gas leakage, often made from materials like rubber, silicone, or metal. O-rings, typically circular elastomer rings, seal by being compressed in a groove, creating a tight barrier against leaks in both static and dynamic applications. The primary difference lies in their sealing mechanism: gaskets rely on surface area coverage, while O-rings depend on radial compression to maintain seal integrity.

Typical Applications: Gaskets vs O-Rings

Gaskets are commonly used in flange connections, pipe joints, and automotive engines to seal irregular surfaces and prevent fluid leakage under varying pressure and temperature conditions. O-rings are preferred in dynamic applications such as hydraulic cylinders, pneumatic systems, and rotating shafts due to their ability to provide a tight seal in both static and dynamic environments. Typical gasket materials include rubber, cork, and metal, while O-rings are often made from elastomers like nitrile, silicone, and Viton for enhanced elasticity and chemical resistance.

Advantages and Disadvantages

Gaskets provide superior sealing for irregular surfaces and high-pressure applications, offering flexibility in material choice and thickness, but they can be bulkier and require more installation space compared to O-rings. O-rings excel in dynamic sealing with excellent resistance to compression and a compact design, making them ideal for rotary and reciprocating movements, yet they are limited in sealing irregular surfaces and high-temperature environments. Both sealing components have distinct advantages and disadvantages depending on application conditions such as pressure, temperature, and surface geometry.

How to Choose Between Gasket and O-Ring

Choosing between a gasket and an O-ring depends on the application's pressure, temperature, and sealing requirements. Gaskets are ideal for static seals in flanged joints, handling broad surface areas and irregular mating surfaces, while O-rings provide reliable sealing in dynamic applications involving rotating or reciprocating parts. Your selection should consider material compatibility, environmental conditions, and the need for ease of installation or replacement to ensure optimal performance.

Conclusion: Which Seal is Right for You?

Choosing between a gasket and an O-ring depends on the application's pressure, temperature, and sealing surface requirements. Gaskets offer versatility in sealing larger, irregular surfaces and can withstand higher temperatures, while O-rings provide reliable sealing for dynamic and static applications with consistent grooves under moderate pressure. Assessing factors like chemical compatibility, mechanical stress, and installation space ensures selecting the optimal seal for durability and performance.

Gasket vs O-ring Infographic

libmatt.com

libmatt.com