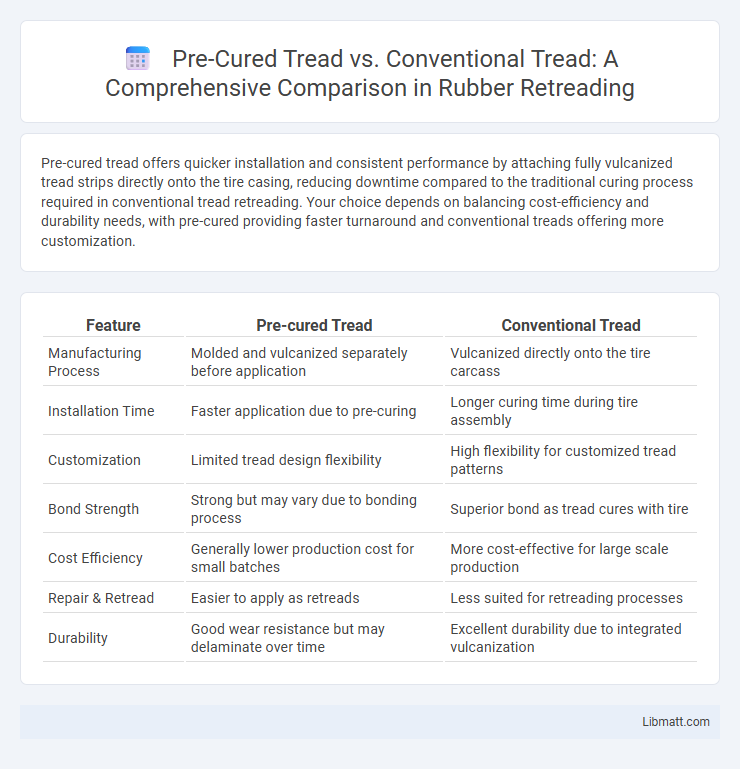

Pre-cured tread offers quicker installation and consistent performance by attaching fully vulcanized tread strips directly onto the tire casing, reducing downtime compared to the traditional curing process required in conventional tread retreading. Your choice depends on balancing cost-efficiency and durability needs, with pre-cured providing faster turnaround and conventional treads offering more customization.

Table of Comparison

| Feature | Pre-cured Tread | Conventional Tread |

|---|---|---|

| Manufacturing Process | Molded and vulcanized separately before application | Vulcanized directly onto the tire carcass |

| Installation Time | Faster application due to pre-curing | Longer curing time during tire assembly |

| Customization | Limited tread design flexibility | High flexibility for customized tread patterns |

| Bond Strength | Strong but may vary due to bonding process | Superior bond as tread cures with tire |

| Cost Efficiency | Generally lower production cost for small batches | More cost-effective for large scale production |

| Repair & Retread | Easier to apply as retreads | Less suited for retreading processes |

| Durability | Good wear resistance but may delaminate over time | Excellent durability due to integrated vulcanization |

Introduction to Tyre Retreading

Pre-cured tread consists of pre-vulcanized rubber strips bonded to the tyre casing, offering consistent quality and faster application, while conventional tread involves applying uncured rubber directly to the casing before vulcanization. Tyre retreading extends tyre life, reduces costs, and promotes sustainability by reusing the tyre carcass with either pre-cured or conventional tread methods. Understanding the differences between these techniques helps you choose the most efficient retreading solution for your fleet management needs.

Understanding Pre-cured Tread Technology

Pre-cured tread technology involves manufacturing tire treads separately and curing them before being bonded to the tire casing, offering enhanced quality control and design flexibility compared to conventional treads vulcanized directly onto the tire. This method improves uniformity, reduces production time, and allows for easier customization of tread patterns and compounds. Pre-cured treads also enable better performance optimization and repair efficiency in commercial and heavy-duty tire applications.

Overview of Conventional Tread Methods

Conventional tread methods involve applying raw rubber directly onto tire casings, followed by curing in a mold to bond the tread to the tire. This process requires precise temperature and pressure control to ensure a durable and uniform tread pattern. You benefit from tried-and-tested techniques that provide strong adhesion and consistent tire performance under various conditions.

Key Differences Between Pre-cured and Conventional Tread

Pre-cured tread involves rubber that is pre-vulcanized before application, ensuring consistent quality and faster installation, while conventional tread uses uncured rubber that vulcanizes during the retreading process, allowing for more customization. Pre-cured tread offers improved environmental benefits due to reduced emissions and energy consumption compared to the higher heat and pressure demands of conventional tread curing. Choosing between pre-cured and conventional tread impacts your tire's durability, performance, and retreading turnaround time based on your specific usage requirements.

Performance Comparison: Durability and Traction

Pre-cured treads offer enhanced durability due to their pre-vulcanized rubber compounds, which resist wear and tear better than conventional treads that cure during the retreading process. Traction performance in pre-cured treads remains consistent because of the controlled manufacturing environment, whereas conventional treads may exhibit variable grip depending on curing conditions and material inconsistencies. Overall, pre-cured treads deliver more reliable performance in both durability and traction for heavy-duty and frequent-use applications.

Cost Analysis: Pre-cured vs Conventional Tread

Pre-cured treads generally offer cost savings due to reduced labor and curing time compared to conventional treads, which require on-site vulcanization and longer processing periods. Conventional treads incur higher expenses from additional equipment, skilled labor, and extended vehicle downtime during application. Overall, pre-cured treads present a more economical option for retreading by minimizing operational costs and increasing efficiency.

Environmental Impact and Sustainability

Pre-cured treads reduce waste by allowing precise manufacturing with minimal scrap compared to conventional treads, which often generate more offcuts during molding. The lower energy consumption in pre-cured tread production decreases carbon emissions, enhancing sustainability and reducing the overall environmental footprint. Utilizing pre-cured treads supports circular economy principles by enabling easier retreading and extending tire life, thereby conserving resources and minimizing landfill waste.

Applications and Suitability for Vehicles

Pre-cured treads are ideal for light to medium-duty vehicles due to their precise fit and efficient installation process, commonly used in retreading passenger cars, vans, and light trucks. Conventional treads offer greater flexibility for heavy-duty and off-road vehicles, providing superior durability and custom tread design suitable for trucks, buses, and commercial fleets. Choosing between pre-cured and conventional treads depends on vehicle load, application frequency, and specific performance requirements.

Maintenance Requirements and Lifespan

Pre-cured treads offer lower maintenance requirements due to their factory-cured rubber, which provides consistent quality and reduces the need for frequent inspections or repairs compared to conventional treads. Conventional treads require more frequent maintenance as the curing occurs during retreading, increasing the risk of defects that can shorten tread lifespan. The lifespan of pre-cured treads is generally longer, benefiting from controlled curing processes and improved adhesion, while conventional treads may have variable durability depending on on-site curing conditions.

Final Verdict: Choosing the Right Tread Method

Pre-cured tread offers consistent quality and faster application by using pre-vulcanized rubber sheets, making it ideal for quick tire retreading with minimal equipment. Conventional tread involves applying raw rubber directly to the casing before vulcanization, allowing for more customization but requiring longer curing times and specialized presses. Selecting the right tread method depends on factors like production volume, equipment availability, and specific performance requirements, with pre-cured favored for efficiency and conventional tread preferred for tailored tire performance.

Pre-cured Tread vs Conventional Tread Infographic

libmatt.com

libmatt.com