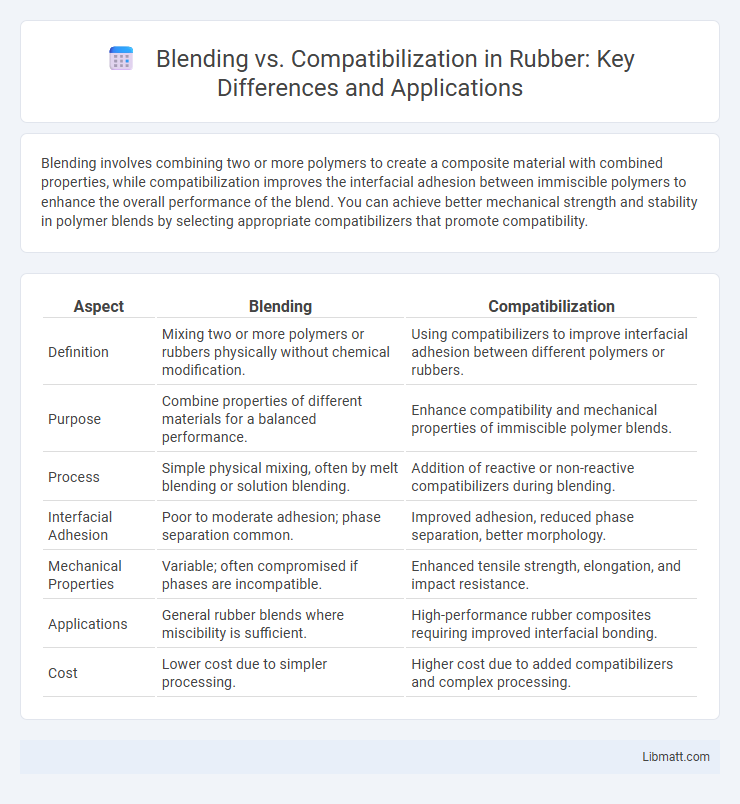

Blending involves combining two or more polymers to create a composite material with combined properties, while compatibilization improves the interfacial adhesion between immiscible polymers to enhance the overall performance of the blend. You can achieve better mechanical strength and stability in polymer blends by selecting appropriate compatibilizers that promote compatibility.

Table of Comparison

| Aspect | Blending | Compatibilization |

|---|---|---|

| Definition | Mixing two or more polymers or rubbers physically without chemical modification. | Using compatibilizers to improve interfacial adhesion between different polymers or rubbers. |

| Purpose | Combine properties of different materials for a balanced performance. | Enhance compatibility and mechanical properties of immiscible polymer blends. |

| Process | Simple physical mixing, often by melt blending or solution blending. | Addition of reactive or non-reactive compatibilizers during blending. |

| Interfacial Adhesion | Poor to moderate adhesion; phase separation common. | Improved adhesion, reduced phase separation, better morphology. |

| Mechanical Properties | Variable; often compromised if phases are incompatible. | Enhanced tensile strength, elongation, and impact resistance. |

| Applications | General rubber blends where miscibility is sufficient. | High-performance rubber composites requiring improved interfacial bonding. |

| Cost | Lower cost due to simpler processing. | Higher cost due to added compatibilizers and complex processing. |

Introduction to Polymer Blending

Polymer blending involves mixing two or more polymers to tailor material properties, offering a cost-effective way to achieve desired mechanical, thermal, or chemical characteristics. Compatibilization enhances the interfacial adhesion between immiscible polymers, improving the blend's homogeneity and overall performance. Understanding polymer blending and compatibilization helps you select suitable materials for optimized product functionality and durability.

Defining Compatibilization in Polymers

Compatibilization in polymers involves adding specific agents to improve the interfacial adhesion between immiscible polymer blends, enhancing their mechanical properties and stability. This process differs from simple blending by modifying the interface at the molecular level, enabling better compatibility and dispersion of distinct polymer phases. Your material's performance can be significantly enhanced by selecting appropriate compatibilizers tailored to the polymer systems involved.

Key Differences Between Blending and Compatibilization

Blending involves physically mixing two or more polymers to combine their properties, often resulting in phase separation due to incompatibility between components. Compatibilization uses specific agents or methods to improve interfacial adhesion and dispersion within polymer blends, promoting enhanced mechanical and thermal properties. The key difference lies in blending being a physical combination, while compatibilization chemically or physically modifies interfaces to achieve stability and improved performance.

Mechanisms of Polymer Blending

Mechanisms of polymer blending involve the physical mixing of two or more polymers to create a material with combined properties, relying on factors such as polymer compatibility, molecular weight, and interfacial tension to influence phase morphology. Incompatible polymer blends often result in phase separation, leading to poor mechanical properties, which drives the need for compatibilization techniques that enhance interfacial adhesion and dispersion. Compatibilizers, such as block or graft copolymers, function by reducing interfacial tension and promoting miscibility through specific chemical interactions, improving overall blend performance and stability.

Role of Compatibilizers in Polymer Systems

Compatibilizers enhance the interfacial adhesion between immiscible polymers in blends, improving morphology and mechanical properties. They act by reducing interfacial tension and promoting phase dispersion, leading to better compatibility and stability of multiphase polymer systems. The use of compatibilizers is critical in achieving uniform stress distribution and preventing phase separation in polymer blends.

Advantages and Limitations of Simple Blending

Simple blending offers a cost-effective and straightforward method for combining polymers, providing improved material properties such as increased toughness and flexibility. However, it often results in phase separation and poor interfacial adhesion due to immiscibility, which limits the mechanical performance and durability of the blend. Your application may require compatibilization techniques to enhance compatibility and achieve superior material stability where simple blending falls short.

Benefits of Compatibilized Polymer Blends

Compatibilized polymer blends exhibit enhanced interfacial adhesion, leading to improved mechanical properties such as tensile strength and impact resistance. These blends enable the combination of polymers with inherently different polarities, resulting in materials with tailored thermal and chemical stability. The addition of compatibilizers reduces phase separation, ensuring a more homogeneous morphology and superior performance in applications like automotive parts and packaging films.

Applications in Industry: Blended vs Compatibilized Polymers

Blended polymers find widespread use in industries such as automotive, packaging, and consumer goods due to their cost-effectiveness and ability to combine base polymer properties, though phase separation limits mechanical performance. Compatibilized polymers enhance interfacial adhesion between immiscible polymers, resulting in superior impact resistance, thermal stability, and durability, making them ideal for high-performance automotive parts, aerospace components, and electronic housings. Your choice between blending and compatibilization depends on application requirements, with compatibilized polymers offering enhanced functionality in demanding industrial environments.

Challenges in Achieving Effective Polymer Compatibilization

Achieving effective polymer compatibilization faces challenges such as poor interfacial adhesion due to immiscibility of polymer blends, which leads to phase separation and weak mechanical properties. Developing compatibilizers that can effectively reduce interfacial tension and promote molecular-level interactions between dissimilar polymers remains complex and requires precise selection of block or graft copolymers tailored to the specific blend system. Processing conditions like temperature, shear rate, and mixing time must also be optimized to facilitate the dispersion and stabilization of dispersed phases, ensuring a uniform morphology and enhanced performance.

Future Trends in Polymer Blending and Compatibilization

Future trends in polymer blending and compatibilization emphasize the development of advanced compatibilizers derived from sustainable bio-based materials, enhancing compatibility between immiscible polymers. You can expect increased use of smart compatibilizers that respond to environmental stimuli, optimizing blend performance in real-time applications. Emerging techniques like reactive blending combined with nanotechnology aim to create multifunctional polymer materials with tailored mechanical and barrier properties for next-generation industries.

Blending vs Compatibilization Infographic

libmatt.com

libmatt.com