Ebonite offers exceptional durability and high resistance to heat, making it ideal for applications requiring long-lasting performance. Soft rubber provides superior flexibility and cushioning, ensuring comfort and shock absorption for your specific needs.

Table of Comparison

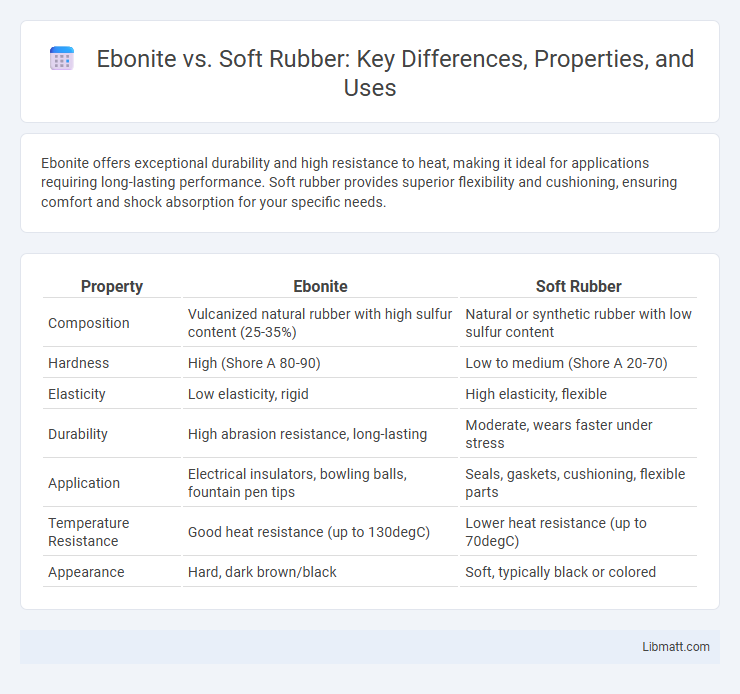

| Property | Ebonite | Soft Rubber |

|---|---|---|

| Composition | Vulcanized natural rubber with high sulfur content (25-35%) | Natural or synthetic rubber with low sulfur content |

| Hardness | High (Shore A 80-90) | Low to medium (Shore A 20-70) |

| Elasticity | Low elasticity, rigid | High elasticity, flexible |

| Durability | High abrasion resistance, long-lasting | Moderate, wears faster under stress |

| Application | Electrical insulators, bowling balls, fountain pen tips | Seals, gaskets, cushioning, flexible parts |

| Temperature Resistance | Good heat resistance (up to 130degC) | Lower heat resistance (up to 70degC) |

| Appearance | Hard, dark brown/black | Soft, typically black or colored |

Introduction to Ebonite and Soft Rubber

Ebonite, also known as hard rubber, is a vulcanized material composed primarily of natural rubber and a high proportion of sulfur, giving it excellent rigidity and durability ideal for applications like bowling balls and musical instruments. Soft rubber, in contrast, refers to natural or synthetic rubber compounds with lower sulfur content and added plasticizers, resulting in flexible, elastic properties suited for seals, gaskets, and flexible molds. The fundamental difference between Ebonite and soft rubber lies in their sulfur content and vulcanization process, determining their hardness, elasticity, and typical use cases.

Composition and Manufacturing Process

Ebonite is a hard, vulcanized rubber composed primarily of natural rubber combined with a high percentage of sulfur, typically around 25-35%, which undergoes prolonged heating during the vulcanization process to enhance its rigidity and durability. Soft rubber, in contrast, contains lower sulfur content and additional plasticizers, resulting in a more flexible material produced through a shorter curing process that prioritizes elasticity. Understanding these differences in composition and manufacturing helps you choose the appropriate rubber for applications requiring either hardness and resilience or softness and flexibility.

Physical Properties Comparison

Ebonite exhibits high hardness and excellent rigidity due to its vulcanized composition, making it resistant to wear and deformation under mechanical stress. Soft rubber offers superior elasticity and flexibility with low hardness, allowing greater shock absorption and cushioning but reduced structural strength. Your choice depends on whether durability and stiffness or flexibility and cushioning are prioritized for the application.

Durability and Longevity

Ebonite offers superior durability and longevity due to its hard, dense composition, making it highly resistant to wear and deformation over time. Soft rubber, while providing excellent grip and comfort, tends to degrade faster under frequent use and exposure to elements. Choosing Ebonite for your bowling ball ensures extended performance and sustained structural integrity during prolonged play.

Flexibility and Elasticity

Ebonite exhibits low flexibility and limited elasticity due to its hard, vulcanized rubber composition, making it ideal for applications requiring rigidity and durability. Soft rubber offers higher flexibility and superior elasticity, allowing it to stretch and return to its original shape easily, which enhances comfort and shock absorption in products like gloves and grips. Your choice between ebonite and soft rubber should consider the specific need for either stiffness or pliability in the intended use.

Applications and Common Uses

Ebonite, known for its high hardness and electrical insulation properties, is commonly used in applications such as bowling balls, electrical switchgear, and fountain pen bodies. Soft rubber, valued for its flexibility and cushioning effect, finds widespread use in seals, gaskets, gloves, and vibration dampening components. Your choice between ebonite and soft rubber depends on whether you need durability and rigidity or elasticity and shock absorption in your application.

Chemical Resistance and Stability

Ebonite exhibits superior chemical resistance and stability compared to soft rubber, making it highly effective for applications involving harsh chemicals and solvents. Soft rubber tends to degrade or swell more rapidly when exposed to oils, acids, and alkalis, whereas ebonite maintains its structural integrity and resists chemical breakdown. When selecting materials for durability under chemically aggressive environments, your choice of ebonite ensures longer-lasting performance and reduced maintenance.

Cost and Availability

Ebonite typically costs more than soft rubber due to its manufacturing process and durability, making it a premium choice for applications requiring long-lasting materials. Soft rubber offers a lower-cost alternative with widespread availability in various grades and formulations, ideal for budget-conscious projects. Your selection depends on balancing upfront investment with accessibility and material performance requirements.

Environmental Impact and Sustainability

Ebonite, made from vulcanized natural rubber, tends to have a lower environmental impact due to its biodegradability and use of renewable materials, whereas soft rubber often involves synthetic components derived from petrochemicals with higher carbon emissions and limited biodegradability. Manufacturers increasingly favor ebonite for sustainable production because it reduces plastic waste and supports eco-friendly disposal. Your choice between Ebonite and soft rubber can significantly influence environmental sustainability, especially in industries prioritizing green products and responsible resource use.

Which Material Should You Choose?

Ebonite offers superior durability and a solid feel, making it ideal for players seeking long-lasting performance and a traditional bowling experience. Soft rubber provides enhanced grip and hook potential, ideal for bowlers who prioritize control and smoother ball motion on oily lanes. Choosing between Ebonite and soft rubber depends on your playing style, lane conditions, and desired ball reaction.

Ebonite vs Soft rubber Infographic

libmatt.com

libmatt.com