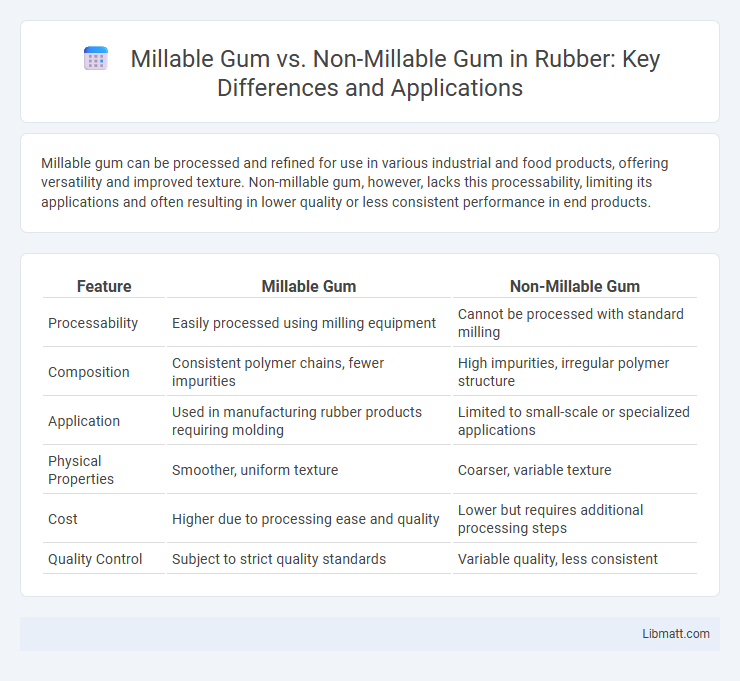

Millable gum can be processed and refined for use in various industrial and food products, offering versatility and improved texture. Non-millable gum, however, lacks this processability, limiting its applications and often resulting in lower quality or less consistent performance in end products.

Table of Comparison

| Feature | Millable Gum | Non-Millable Gum |

|---|---|---|

| Processability | Easily processed using milling equipment | Cannot be processed with standard milling |

| Composition | Consistent polymer chains, fewer impurities | High impurities, irregular polymer structure |

| Application | Used in manufacturing rubber products requiring molding | Limited to small-scale or specialized applications |

| Physical Properties | Smoother, uniform texture | Coarser, variable texture |

| Cost | Higher due to processing ease and quality | Lower but requires additional processing steps |

| Quality Control | Subject to strict quality standards | Variable quality, less consistent |

Introduction to Millable and Non-Millable Gum

Millable gum refers to raw natural rubber that can be processed and refined into finished rubber products, whereas non-millable gum typically denotes rubber that is either unprocessed or unsuitable for milling due to impurities or damaged quality. The distinction between millable and non-millable gum significantly impacts the rubber manufacturing industry, influencing the efficiency and quality of rubber production. Understanding whether your material qualifies as millable gum helps optimize processing techniques and ensures consistent product performance.

Definition of Millable Gum

Millable gum refers to a type of natural or synthetic gum that can be processed or milled into fine particles for further manufacturing use, such as in adhesives, pharmaceuticals, or food products. Non-millable gum lacks this property and cannot be effectively ground or milled without losing its functional characteristics. Understanding the definition of millable gum helps you select the appropriate material for industrial applications requiring consistent texture and reactivity.

Definition of Non-Millable Gum

Non-millable gum refers to the sticky, gummy substances present in crude oil that hinder efficient refinery processing and cannot be removed during standard milling procedures. Unlike millable gum, which can be broken down or separated through mechanical or chemical methods, non-millable gum remains insoluble and causes equipment fouling and processing disruptions. Its presence significantly impacts refining efficiency and increases operational costs due to the need for specialized treatment or blending techniques.

Key Differences Between Millable and Non-Millable Gum

Millable gum is characterized by its ability to be processed and refined into usable products through mechanical milling, while non-millable gum cannot undergo such refinement due to its chemical or physical properties. The key differences include texture, usability, and industrial applications--millable gum is versatile for manufacturing chewing gum and food additives, whereas non-millable gum is primarily used in natural or raw forms like traditional resins and adhesives. Understanding these distinctions helps you select the appropriate gum type for specific commercial or consumer needs.

Chemical Composition Comparison

Millable gum contains higher concentrations of natural polymers such as polyisoprene, contributing to its elasticity and processability in manufacturing. Non-millable gum typically exhibits lower polymer content and increased impurities, resulting in reduced flexibility and difficulties during processing. Understanding these chemical composition differences helps you select the appropriate gum type for specific industrial applications.

Manufacturing Processes

Millable gum undergoes a controlled manufacturing process where the gum base is softened and blended with additives to create a pliable, moldable consistency ideal for rolling, extruding, and shaping. Non-millable gum, however, is produced through a simpler process where the base does not require softening or milling, resulting in a firmer, less flexible texture that limits manufacturing techniques to cutting or scoring. Your choice between millable and non-millable gum affects production speed, mold complexity, and the final product's texture.

Applications of Millable Gum

Millable gum is extensively used in manufacturing products that require high flexibility, such as automotive parts, footwear soles, and flexible tubing, due to its excellent processing properties and consistent curing. Unlike non-millable gum, which may be more brittle and less workable, millable gum allows for efficient mixing and shaping with additives and fillers, making it ideal for custom rubber formulations. Your production processes benefit from millable gum's ability to be easily molded and vulcanized into durable, high-performance rubber components.

Applications of Non-Millable Gum

Non-millable gum finds critical applications in specialized industries such as pharmaceuticals, food additives, and cosmetics, where its unique functional properties like viscosity and emulsification are essential. It is often used as a stabilizer, thickener, or binder in formulations requiring precise texture and consistency, particularly in gluten-free and low-calorie products. Its resistance to milling processes preserves its molecular structure, making it ideal for sensitive chemical and biological applications.

Advantages and Disadvantages

Millable gum offers advantages such as consistent texture and ease of processing, making it ideal for uniform product manufacturing but may have limitations in flavor retention and naturalness. Non-millable gum provides a more authentic taste and can contain fewer additives, appealing to consumers seeking natural products, though it often presents challenges in processing and variable texture. The choice depends on balancing production efficiency and product quality based on the targeted consumer preference.

Choosing the Right Gum for Specific Applications

Millable gum offers superior pliability and strength, making it ideal for applications requiring extensive molding or shaping, such as in chewing gum production. Non-millable gum is better suited for items where structural integrity and shelf stability are prioritized, like in certain confectionery coatings or adhesives. Your choice between millable and non-millable gum should align with the specific mechanical and sensory properties needed for your product.

Millable gum vs Non-millable gum Infographic

libmatt.com

libmatt.com