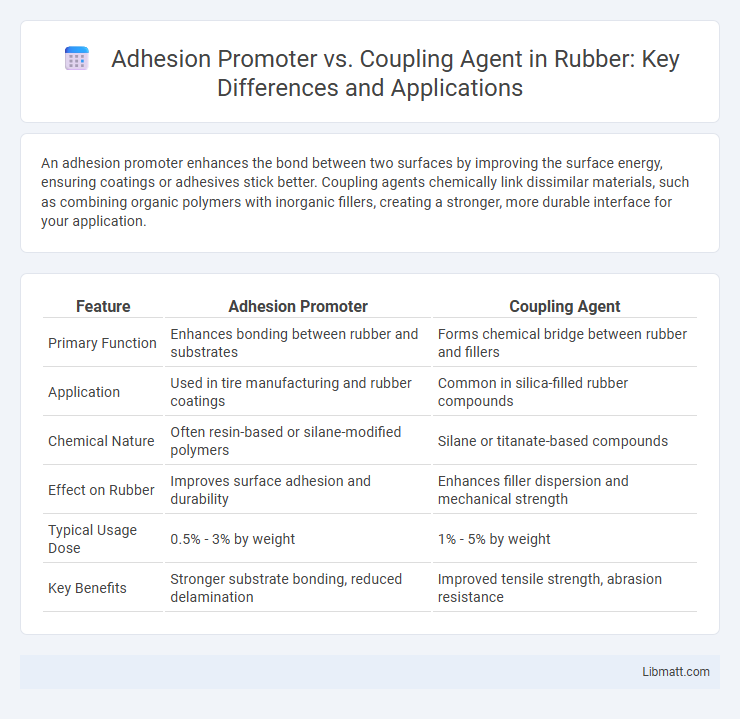

An adhesion promoter enhances the bond between two surfaces by improving the surface energy, ensuring coatings or adhesives stick better. Coupling agents chemically link dissimilar materials, such as combining organic polymers with inorganic fillers, creating a stronger, more durable interface for your application.

Table of Comparison

| Feature | Adhesion Promoter | Coupling Agent |

|---|---|---|

| Primary Function | Enhances bonding between rubber and substrates | Forms chemical bridge between rubber and fillers |

| Application | Used in tire manufacturing and rubber coatings | Common in silica-filled rubber compounds |

| Chemical Nature | Often resin-based or silane-modified polymers | Silane or titanate-based compounds |

| Effect on Rubber | Improves surface adhesion and durability | Enhances filler dispersion and mechanical strength |

| Typical Usage Dose | 0.5% - 3% by weight | 1% - 5% by weight |

| Key Benefits | Stronger substrate bonding, reduced delamination | Improved tensile strength, abrasion resistance |

Introduction to Adhesion Promoters and Coupling Agents

Adhesion promoters and coupling agents enhance the bonding between different materials by improving surface interactions at the molecular level. Adhesion promoters are typically used to increase the compatibility between coatings or adhesives and substrates, while coupling agents like silanes chemically bridge organic and inorganic materials for stronger, more durable bonds. Understanding these substances helps optimize your manufacturing or repair processes by ensuring superior adhesion performance.

Defining Adhesion Promoters

Adhesion promoters are specialized chemical agents designed to enhance the bond between two dissimilar materials by improving surface compatibility and increasing intermolecular forces. These substances typically form a molecular bridge that facilitates stronger adhesion, particularly in coatings, adhesives, and composite materials. Unlike coupling agents, which chemically bond two different phases, adhesion promoters primarily focus on modifying surface energy to optimize physical adhesion.

What Are Coupling Agents?

Coupling agents are specialized chemical compounds that enhance the bond between two dissimilar materials, such as organic polymers and inorganic surfaces, by forming a molecular bridge at the interface. These agents improve adhesion, mechanical strength, and durability in composites, coatings, adhesives, and sealants. Common coupling agents include silanes, titanates, and zirconates, each tailored for specific material compatibility and functional performance.

Key Differences Between Adhesion Promoters and Coupling Agents

Adhesion promoters enhance the bond strength between two surfaces by improving compatibility and surface energy, primarily used in coatings and adhesives applications. Coupling agents chemically link dissimilar materials like organic polymers and inorganic substrates by forming a covalent or ionic bond, frequently used in composite materials and reinforcement processes. The key difference lies in adhesion promoters modifying surface properties to increase adhesion, while coupling agents create chemical bridges ensuring a durable and stable interface.

Mechanisms of Action: How Adhesion Promoters Work

Adhesion promoters enhance the bond between dissimilar materials by modifying surface energy to improve wettability and increase chemical compatibility. These substances create a molecular bridge through the formation of covalent or hydrogen bonds between the substrate and adhesive layers, thereby strengthening interfacial adhesion. Their mechanisms often involve surface activation, such as the introduction of reactive functional groups or the removal of contaminants, to facilitate stronger intermolecular interactions.

Mechanisms of Action: How Coupling Agents Function

Coupling agents function by forming chemical bonds between dissimilar materials, typically inorganic fillers and organic polymers, enhancing interfacial adhesion and mechanical strength. These agents possess dual reactive groups, such as organofunctional and hydrolyzable groups, which react with both the substrate and the polymer matrix. This dual reactivity facilitates improved dispersion, durability, and performance in composite materials and coatings.

Applications of Adhesion Promoters in Industry

Adhesion promoters are widely used in industries such as automotive, electronics, and construction to enhance the bond strength between dissimilar materials like metals, plastics, and composites. These chemicals improve paint adhesion on metal surfaces, facilitate stronger seals in electronic components, and increase durability in coatings applied to concrete and wood. Their application ensures long-lasting performance and resistance to environmental factors in industrial manufacturing processes.

Typical Uses of Coupling Agents Across Sectors

Coupling agents play a crucial role in enhancing the bond between dissimilar materials, such as polymers and metals or glass, widely used in automotive, aerospace, and construction industries to improve durability and performance. In electronics, coupling agents facilitate better adhesion and electrical properties in composite materials, while in coatings and adhesives manufacturing, they ensure stronger, long-lasting bonds. Your choice of coupling agent depends on the specific material interface and desired mechanical properties for optimal results.

Selecting the Right Option: Factors to Consider

When selecting between an adhesion promoter and a coupling agent, consider the substrate type, environmental exposure, and desired bond strength for your project. Adhesion promoters enhance surface energy and improve initial bonding on non-reactive or smooth surfaces, while coupling agents chemically bond dissimilar materials by forming molecular bridges. Evaluating compatibility with materials, application conditions, and long-term performance ensures you choose the right option to optimize durability and adhesion efficiency.

Future Trends in Surface Modification Technologies

Future trends in surface modification technologies emphasize the development of multifunctional adhesion promoters and coupling agents that enhance bond strength, durability, and environmental resistance for advanced composites and polymers. Innovations harness nanotechnology and bio-based chemicals to create eco-friendly, sustainable solutions that improve interfacial compatibility and mechanical performance. The integration of smart surface treatments capable of responding to environmental stimuli is advancing material adaptability in aerospace, automotive, and biomedical industries.

Adhesion Promoter vs Coupling Agent Infographic

libmatt.com

libmatt.com