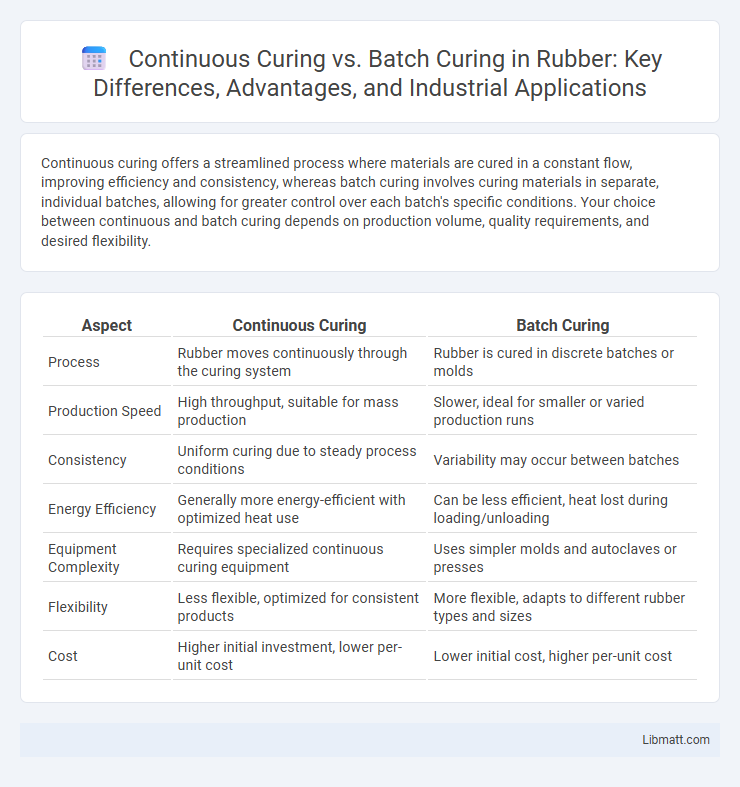

Continuous curing offers a streamlined process where materials are cured in a constant flow, improving efficiency and consistency, whereas batch curing involves curing materials in separate, individual batches, allowing for greater control over each batch's specific conditions. Your choice between continuous and batch curing depends on production volume, quality requirements, and desired flexibility.

Table of Comparison

| Aspect | Continuous Curing | Batch Curing |

|---|---|---|

| Process | Rubber moves continuously through the curing system | Rubber is cured in discrete batches or molds |

| Production Speed | High throughput, suitable for mass production | Slower, ideal for smaller or varied production runs |

| Consistency | Uniform curing due to steady process conditions | Variability may occur between batches |

| Energy Efficiency | Generally more energy-efficient with optimized heat use | Can be less efficient, heat lost during loading/unloading |

| Equipment Complexity | Requires specialized continuous curing equipment | Uses simpler molds and autoclaves or presses |

| Flexibility | Less flexible, optimized for consistent products | More flexible, adapts to different rubber types and sizes |

| Cost | Higher initial investment, lower per-unit cost | Lower initial cost, higher per-unit cost |

Introduction to Curing Methods

Continuous curing and batch curing are two essential industrial processes used to harden or set materials such as rubber, plastics, and composites. Continuous curing involves a steady, uninterrupted flow of material through a curing system, optimizing production efficiency and consistency. Your choice between these methods depends on factors like production volume, material type, and desired product properties.

What is Continuous Curing?

Continuous curing is a manufacturing process where materials are cured in a non-stop flow, allowing for consistent heat or chemical treatment along a production line. This method enhances efficiency by maintaining steady curing conditions, reducing cycle times compared to batch curing. You can achieve higher throughput and uniform product quality with continuous curing systems used in industries like composites and rubber manufacturing.

What is Batch Curing?

Batch curing is a process where materials or products are cured in discrete, separate groups within a controlled environment, allowing for precise temperature and time management. This method ensures uniform curing by treating all items simultaneously, often used in industries like composites, rubber, and coatings. Understanding batch curing helps you select the appropriate technique for your production requirements, balancing quality and efficiency.

Key Differences Between Continuous and Batch Curing

Continuous curing offers a streamlined process with non-stop production, maximizing efficiency and ensuring uniform heat distribution, while batch curing processes materials in fixed quantities with scheduled intervals, allowing more control over curing time and temperature. The primary difference lies in throughput capacity; continuous curing systems handle higher volumes suitable for large-scale manufacturing, whereas batch curing is ideal for smaller runs demanding precision and customization. Your choice depends on production scale, consistency requirements, and material sensitivity to temperature variations during the curing phase.

Efficiency and Throughput Analysis

Continuous curing systems offer superior efficiency and higher throughput by enabling nonstop processing, which minimizes downtime and accelerates production cycles compared to batch curing methods. Batch curing typically involves longer cycle times and frequent equipment reset periods, reducing overall operational efficiency and limiting throughput capacity. Analyzing productivity metrics reveals continuous curing can increase output by up to 30%, making it preferable for large-scale manufacturing environments requiring consistent, high-volume production.

Quality and Consistency Comparison

Continuous curing provides superior quality and consistency by maintaining uniform temperature and processing conditions throughout the production run, reducing variability in material properties. Batch curing can result in inconsistencies due to fluctuations in temperature and curing time between batches, leading to variable mechanical strength and surface finish. The controlled environment of continuous curing enhances repeatability and product reliability, making it ideal for high-volume manufacturing.

Cost Implications of Each Method

Continuous curing offers lower operational costs due to its automated, high-throughput nature, reducing labor expenses and energy consumption per unit. Batch curing, while more flexible for small-scale or specialized production, incurs higher costs from frequent setup changes, longer cycle times, and increased labor. Your choice impacts overall expenditure, with continuous curing being more cost-effective for large-scale manufacturing and batch curing better suited for limited runs or varied product lines.

Industry Applications for Continuous and Batch Curing

Continuous curing is widely employed in industries requiring high-volume production and consistent quality, such as automotive manufacturing, electronics, and packaging. Batch curing suits specialized applications demanding precise control over curing parameters, commonly found in aerospace composites, custom rubber molding, and medical device fabrication. Both methods optimize production efficiency and product performance based on specific industrial needs and material properties.

Environmental and Energy Considerations

Continuous curing processes improve energy efficiency by maintaining constant temperature control and reducing heat losses compared to batch curing, which involves cyclic heating and cooling phases. Batch curing typically consumes more energy due to repeated oven start-ups and cooldowns, leading to higher emissions and increased environmental impact. Optimizing continuous curing systems can further decrease carbon footprints through lower energy consumption and improved process consistency.

Choosing the Right Curing Method for Your Needs

Continuous curing offers consistent temperature control and higher production efficiency, making it ideal for large-scale manufacturing processes requiring uniform quality. Batch curing provides greater flexibility and customization, allowing precise control over curing cycles for specialized applications or smaller production runs. Selecting the right curing method depends on factors such as production volume, material type, and desired product properties to optimize performance and cost-effectiveness.

Continuous curing vs Batch curing Infographic

libmatt.com

libmatt.com