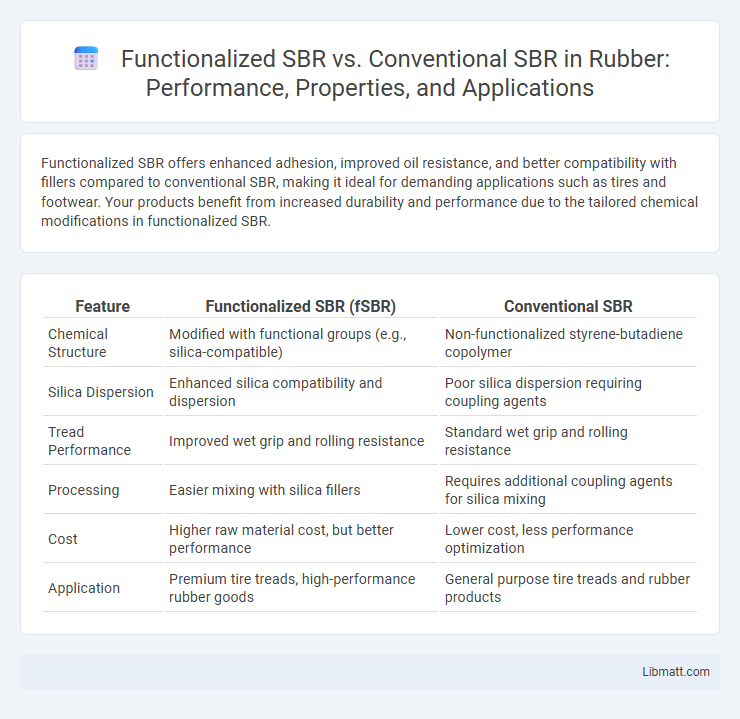

Functionalized SBR offers enhanced adhesion, improved oil resistance, and better compatibility with fillers compared to conventional SBR, making it ideal for demanding applications such as tires and footwear. Your products benefit from increased durability and performance due to the tailored chemical modifications in functionalized SBR.

Table of Comparison

| Feature | Functionalized SBR (fSBR) | Conventional SBR |

|---|---|---|

| Chemical Structure | Modified with functional groups (e.g., silica-compatible) | Non-functionalized styrene-butadiene copolymer |

| Silica Dispersion | Enhanced silica compatibility and dispersion | Poor silica dispersion requiring coupling agents |

| Tread Performance | Improved wet grip and rolling resistance | Standard wet grip and rolling resistance |

| Processing | Easier mixing with silica fillers | Requires additional coupling agents for silica mixing |

| Cost | Higher raw material cost, but better performance | Lower cost, less performance optimization |

| Application | Premium tire treads, high-performance rubber goods | General purpose tire treads and rubber products |

Introduction to SBR: Functionalized vs Conventional

Styrene-Butadiene Rubber (SBR) is a synthetic polymer widely used in tire manufacturing and industrial applications due to its durability and abrasion resistance. Functionalized SBR incorporates specific chemical groups to enhance compatibility with fillers and improve mechanical properties, while conventional SBR lacks these modifications, often resulting in lower performance under demanding conditions. Your choice between functionalized and conventional SBR impacts the efficiency, longevity, and quality of the final product, especially in applications requiring superior strength and elasticity.

Chemical Structure Differences

Functionalized Styrene-Butadiene Rubber (SBR) incorporates polar functional groups, such as carboxyl, hydroxyl, or epoxy groups, within its polymer chain, enhancing its compatibility and interaction with fillers and other materials. Conventional SBR consists primarily of non-polar styrene and butadiene monomers, resulting in limited polarity and weaker interfacial bonding. These chemical structure differences lead to improved mechanical properties and processability in functionalized SBR compared to conventional SBR.

Key Manufacturing Processes

Functionalized Styrene-Butadiene Rubber (SBR) undergoes specialized polymerization techniques such as controlled radical polymerization or the introduction of functional monomers, resulting in enhanced compatibility and reactive sites for improved performance in applications. Conventional SBR is typically produced through emulsion polymerization, yielding a non-functionalized polymer with standard mechanical properties and broad industrial use. The key manufacturing difference lies in the incorporation of functional groups during synthesis, which tailor the polymer characteristics for specific end-use requirements.

Performance in Tire Applications

Functionalized SBR offers superior performance in tire applications compared to conventional SBR due to its enhanced compatibility with fillers like silica, resulting in improved wet traction and reduced rolling resistance. Its tailored molecular structure leads to better abrasion resistance and durability, extending tire lifespan under demanding conditions. Your tires benefit from improved fuel efficiency and safety, making functionalized SBR the preferred choice for high-performance and eco-friendly tires.

Rolling Resistance and Fuel Efficiency

Functionalized SBR (Styrene-Butadiene Rubber) exhibits significantly lower rolling resistance than conventional SBR, contributing to enhanced fuel efficiency in automotive tires. The modified polymer chains in functionalized SBR improve molecular interaction and energy dissipation, reducing hysteresis losses during tire deformation. This optimized rubber composition results in decreased fuel consumption and reduced CO2 emissions compared to tires made with traditional SBR.

Wet and Dry Grip Comparison

Functionalized SBR (Styrene-Butadiene Rubber) offers superior wet and dry grip compared to conventional SBR due to its enhanced polymer structure and surface properties that increase tire-road contact and adhesion. Wet grip improvements result from better water dispersion and tire flexibility, reducing hydroplaning risks, while dry grip benefits from optimized abrasion resistance and tread compound elasticity. Your tire performance, especially in varying weather conditions, can significantly improve with functionalized SBR, delivering safer handling and enhanced traction.

Abrasion Resistance and Tread Wear

Functionalized SBR exhibits superior abrasion resistance compared to conventional SBR due to enhanced polymer chain interactions and improved filler dispersion. This increased durability significantly reduces tread wear in tire applications, extending service life and performance reliability. The incorporation of functional groups in Functionalized SBR optimizes rubber-filler bonding, resulting in enhanced mechanical properties crucial for demanding road conditions.

Environmental Impact and Sustainability

Functionalized Styrene-Butadiene Rubber (SBR) incorporates reactive chemical groups that enhance compatibility with fillers, reducing the need for additional processing aids and thus lowering overall environmental emissions compared to conventional SBR. This improved interaction leads to increased product durability and recyclability, supporting sustainable material lifecycle management in automotive and industrial applications. Your choice of functionalized SBR contributes to reducing carbon footprint and minimizing waste generation, aligning with eco-friendly manufacturing practices.

Cost and Market Availability

Functionalized SBR typically costs more than conventional SBR due to enhanced performance features and specialized chemical modifications. Market availability of functionalized SBR is more limited, often found through niche suppliers or for specific industrial applications, while conventional SBR remains widely accessible and cost-effective for general use. Your selection between these depends on balancing budget constraints with performance needs and supply considerations.

Future Trends in SBR Development

Functionalized SBR incorporates chemically modified polymers that enhance properties such as adhesion, durability, and heat resistance compared to conventional SBR, making it more adaptable for advanced industrial applications. Future trends in SBR development emphasize sustainability, with a focus on bio-based monomers, improved recyclability, and enhanced performance through nanotechnology integration. Your choices in SBR materials will increasingly benefit from innovations that balance environmental impact with superior mechanical and chemical properties.

Functionalized SBR vs Conventional SBR Infographic

libmatt.com

libmatt.com