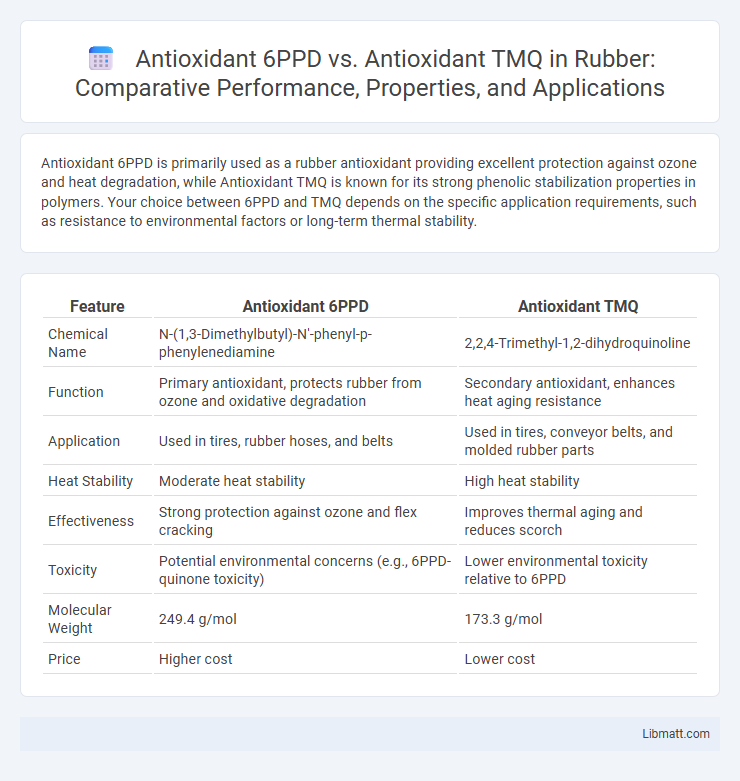

Antioxidant 6PPD is primarily used as a rubber antioxidant providing excellent protection against ozone and heat degradation, while Antioxidant TMQ is known for its strong phenolic stabilization properties in polymers. Your choice between 6PPD and TMQ depends on the specific application requirements, such as resistance to environmental factors or long-term thermal stability.

Table of Comparison

| Feature | Antioxidant 6PPD | Antioxidant TMQ |

|---|---|---|

| Chemical Name | N-(1,3-Dimethylbutyl)-N'-phenyl-p-phenylenediamine | 2,2,4-Trimethyl-1,2-dihydroquinoline |

| Function | Primary antioxidant, protects rubber from ozone and oxidative degradation | Secondary antioxidant, enhances heat aging resistance |

| Application | Used in tires, rubber hoses, and belts | Used in tires, conveyor belts, and molded rubber parts |

| Heat Stability | Moderate heat stability | High heat stability |

| Effectiveness | Strong protection against ozone and flex cracking | Improves thermal aging and reduces scorch |

| Toxicity | Potential environmental concerns (e.g., 6PPD-quinone toxicity) | Lower environmental toxicity relative to 6PPD |

| Molecular Weight | 249.4 g/mol | 173.3 g/mol |

| Price | Higher cost | Lower cost |

Introduction to Antioxidants in Rubber Industry

Antioxidants like 6PPD and TMQ play crucial roles in the rubber industry by preventing oxidative degradation that leads to brittleness and loss of elasticity. 6PPD provides excellent protection against ozone and flex cracking, making it ideal for tire manufacturing, while TMQ offers superior thermal stability and is effective in maintaining rubber's physical properties during high-temperature processing. Your choice between these antioxidants depends on the specific application requirements and environmental conditions faced by the rubber product.

Overview of Antioxidant 6PPD

Antioxidant 6PPD is a widely used polymer additive designed to protect rubber products from ozone and oxidative degradation, significantly extending the lifespan of tires and industrial rubber goods. It works by scavenging free radicals and preventing chain reactions that cause premature aging and cracking under exposure to environmental stressors. Your rubber formulations benefit from 6PPD's high compatibility and efficient protection, making it an essential component for maintaining durability and performance.

Properties of Antioxidant TMQ

Antioxidant TMQ (2,4,7-trimethyl-1,2-dihydroquinoline) exhibits excellent thermal stability and strong resistance to oxidation, making it highly effective in rubber compounding applications. It primarily functions as a secondary antioxidant, preventing polymer degradation by scavenging free radicals and decomposing hydroperoxides. TMQ's superior compatibility with synthetic polymers and resistance to extraction enhance its durability compared to antioxidants like 6PPD.

Chemical Structure Comparison: 6PPD vs TMQ

Antioxidant 6PPD features a p-phenylenediamine core with N-phenyl substitutions, enhancing its reactivity against ozone and oxidative degradation in rubber compounds. In contrast, Antioxidant TMQ is structured as a trisubstituted aromatic amine containing a tetramethyl-1,2-dihydroquinoline ring, offering superior thermal stability and prolonged protection in polymer applications. Your selection between 6PPD and TMQ should consider the specific chemical stability required for your material's oxidative resistance.

Mechanisms of Action: How 6PPD and TMQ Work

Antioxidant 6PPD functions primarily by scavenging free radicals and inhibiting ozone-induced rubber degradation through its p-phenylenediamine structure, which offers superior protection in tire polymers. Antioxidant TMQ (tetramethylthiuram disulfide) operates by donating hydrogen atoms to stabilize polymer radicals, effectively preventing the chain reactions responsible for oxidative deterioration in elastomers. The distinct molecular actions of 6PPD and TMQ make them complementary choices for enhancing rubber durability under varying environmental stressors.

Effectiveness in Heat and Oxidation Resistance

Antioxidant 6PPD demonstrates superior heat and oxidation resistance due to its ability to effectively scavenge free radicals generated during rubber processing and service life, thereby extending tire durability. Antioxidant TMQ, while also providing protection, tends to be less effective at higher temperatures and prolonged oxidation conditions, leading to faster degradation in polymer matrices. The incorporation of 6PPD is preferred in applications demanding enhanced thermal stability and resistance to oxidative aging.

Environmental Impact and Safety Concerns

Antioxidant 6PPD, widely used in tire manufacturing, has raised environmental concerns due to its transformation into toxic byproducts affecting aquatic life. Antioxidant TMQ, known for its stability and lower toxicity, presents fewer environmental risks and is considered safer for use in rubber formulations. Your choice between these antioxidants can influence both environmental safety and regulatory compliance in industrial applications.

Applications in Tire and Rubber Manufacturing

Antioxidant 6PPD is extensively used in tire manufacturing for its superior anti-aging properties, effectively protecting rubber compounds from ozone and oxidative degradation. Antioxidant TMQ offers strong thermal stability and is commonly applied in high-temperature rubber processing to maintain the mechanical integrity of tires. Your selection between 6PPD and TMQ should consider the specific environmental and performance demands of tire and rubber products.

Regulatory Status of 6PPD and TMQ

Antioxidant 6PPD faces increasing regulatory scrutiny due to its environmental toxicity, particularly its impact on aquatic life, leading to usage restrictions or bans in several regions. Antioxidant TMQ, widely accepted for tire and rubber stabilization, maintains a more favorable regulatory status with fewer environmental concerns and broader compliance under international chemical safety standards. Regulatory agencies prioritize alternatives like TMQ as safer options in applications demanding antioxidants, influencing market shifts and formulation strategies.

Future Trends in Antioxidant Development

Antioxidant 6PPD is widely recognized for its superior rubber protection and weathering resistance, while Antioxidant TMQ excels in thermal stability and processing efficiency. Future trends indicate a shift towards enhancing eco-friendly formulations and improving synergistic effects between antioxidants like 6PPD and TMQ to extend product lifespan and reduce environmental impact. Your choice of antioxidants will increasingly depend on balancing performance with sustainability requirements in emerging applications.

Antioxidant 6PPD vs Antioxidant TMQ Infographic

libmatt.com

libmatt.com