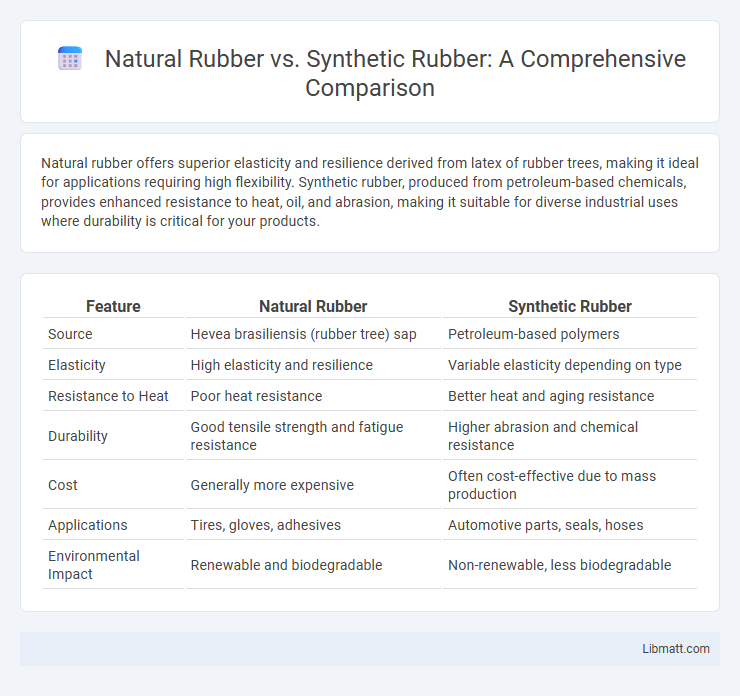

Natural rubber offers superior elasticity and resilience derived from latex of rubber trees, making it ideal for applications requiring high flexibility. Synthetic rubber, produced from petroleum-based chemicals, provides enhanced resistance to heat, oil, and abrasion, making it suitable for diverse industrial uses where durability is critical for your products.

Table of Comparison

| Feature | Natural Rubber | Synthetic Rubber |

|---|---|---|

| Source | Hevea brasiliensis (rubber tree) sap | Petroleum-based polymers |

| Elasticity | High elasticity and resilience | Variable elasticity depending on type |

| Resistance to Heat | Poor heat resistance | Better heat and aging resistance |

| Durability | Good tensile strength and fatigue resistance | Higher abrasion and chemical resistance |

| Cost | Generally more expensive | Often cost-effective due to mass production |

| Applications | Tires, gloves, adhesives | Automotive parts, seals, hoses |

| Environmental Impact | Renewable and biodegradable | Non-renewable, less biodegradable |

Introduction to Natural and Synthetic Rubber

Natural rubber, derived from the latex sap of Hevea brasiliensis trees, offers excellent elasticity, tensile strength, and resilience, making it ideal for tires, gloves, and adhesives. Synthetic rubber, produced from petroleum-based monomers such as styrene and butadiene, provides enhanced resistance to heat, chemicals, and abrasion, used extensively in industrial applications and automotive parts. The choice between natural and synthetic rubber depends on performance requirements, cost, and environmental factors, with synthetic variants often tailored for specific durability needs.

Origins and Production Processes

Natural rubber originates from the latex sap of Hevea brasiliensis trees, primarily cultivated in Southeast Asia, and undergoes tapping and coagulation to produce raw rubber sheets. Synthetic rubber is derived from petrochemical monomers such as styrene and butadiene through polymerization processes like emulsion or solution polymerization in chemical plants. The production of natural rubber depends on renewable agricultural resources, while synthetic rubber manufacturing relies on non-renewable fossil fuels and complex industrial synthesis methods.

Chemical Composition and Structure

Natural rubber is primarily composed of cis-1,4-polyisoprene, a polymer with a high molecular weight and a crystalline structure that provides excellent elasticity and resilience. Synthetic rubber, such as styrene-butadiene rubber (SBR) or nitrile rubber (NBR), consists of copolymers synthesized from petrochemical monomers, offering tailored chemical properties like oil resistance and heat stability. The molecular architecture of natural rubber features long, naturally occurring polymer chains, whereas synthetic rubbers have more controlled, customizable polymer chain compositions and cross-linking densities.

Key Physical Properties Comparison

Natural rubber offers superior elasticity and tensile strength, making it ideal for applications requiring high flexibility and resilience. Synthetic rubber, such as styrene-butadiene (SBR) and nitrile rubber (NBR), provides enhanced resistance to oil, heat, and aging, ensuring durability in harsh environments. Understanding these key physical properties helps you select the most suitable rubber type based on performance needs and operating conditions.

Environmental Impact and Sustainability

Natural rubber, derived from rubber trees, offers greater sustainability due to its renewable source and ability to absorb carbon dioxide during growth, reducing environmental impact. Synthetic rubber, produced from petroleum-based chemicals, contributes to higher carbon emissions and relies on non-renewable fossil fuels, increasing ecological footprint. Your choice of natural rubber supports eco-friendly practices and promotes a circular economy in the rubber industry.

Cost and Economic Considerations

Natural rubber typically incurs higher production costs due to reliance on rubber tree plantations and seasonal harvesting, leading to price volatility influenced by climate and labor factors. Synthetic rubber, derived from petrochemical sources, generally offers more stable pricing and large-scale production efficiencies, benefiting from advancements in chemical synthesis and refining. Economic considerations favor synthetic rubber in industries requiring consistent supply and cost control, while natural rubber remains preferred for applications demanding superior elasticity and resilience.

Performance in Industrial Applications

Natural rubber offers superior elasticity, resilience, and tensile strength, making it ideal for products requiring high durability and flexibility such as tires, seals, and vibration dampers. Synthetic rubber, including types like styrene-butadiene and nitrile rubber, provides enhanced resistance to oils, chemicals, and extreme temperatures, ensuring consistent performance in harsh industrial environments. Choosing between natural and synthetic rubber depends on your specific application demands for wear resistance, environmental exposure, and mechanical properties.

Advantages of Natural Rubber

Natural rubber offers superior elasticity, tensile strength, and resilience compared to synthetic rubber, making it ideal for applications requiring high flexibility and durability, such as tires and medical gloves. Its biodegradability ensures an environmentally friendly option, reducing long-term ecological impact as opposed to petroleum-based synthetic alternatives. You benefit from natural rubber's excellent resistance to wear, heat, and abrasion, which enhances product performance and longevity.

Benefits of Synthetic Rubber

Synthetic rubber offers enhanced resistance to heat, oil, and chemicals compared to natural rubber, making it ideal for automotive and industrial applications. Its consistent quality and versatility enable precise manufacturing of products like tires, seals, and hoses with improved durability. Synthetic rubber also provides better performance in extreme temperatures and longer lifespan under harsh environmental conditions.

Choosing Between Natural and Synthetic Rubber

Choosing between natural and synthetic rubber depends on your specific application requirements, such as durability, elasticity, and resistance to chemicals or temperature fluctuations. Natural rubber offers excellent elasticity and tensile strength, making it ideal for products requiring flexibility and resilience, while synthetic rubber provides superior resistance to oil, heat, and aging, suited for industrial uses and harsh environments. Assess your performance needs and environmental conditions to determine whether the sustainable, biodegradable qualities of natural rubber or the customizable properties of synthetic rubber best suit your project.

Natural Rubber vs Synthetic Rubber Infographic

libmatt.com

libmatt.com