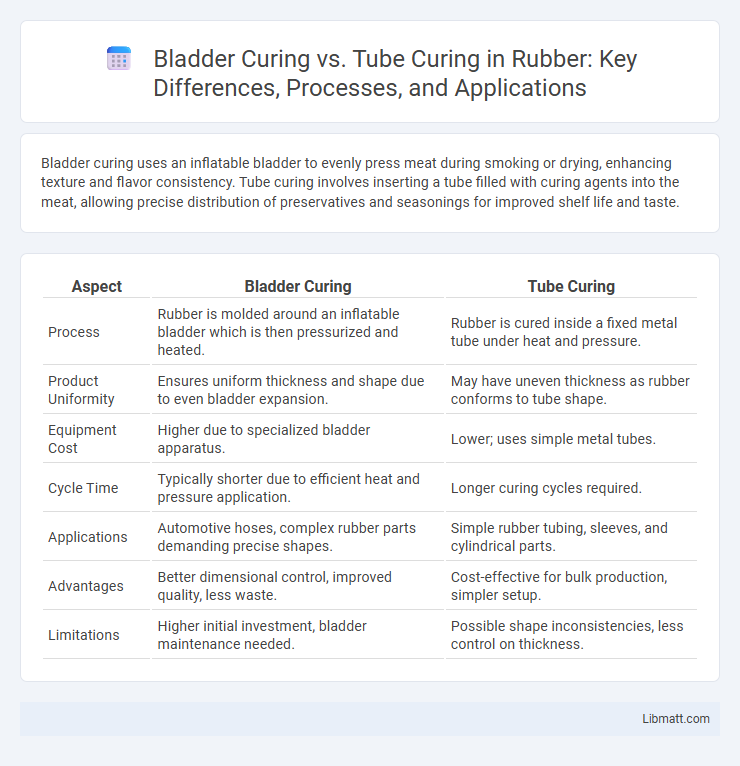

Bladder curing uses an inflatable bladder to evenly press meat during smoking or drying, enhancing texture and flavor consistency. Tube curing involves inserting a tube filled with curing agents into the meat, allowing precise distribution of preservatives and seasonings for improved shelf life and taste.

Table of Comparison

| Aspect | Bladder Curing | Tube Curing |

|---|---|---|

| Process | Rubber is molded around an inflatable bladder which is then pressurized and heated. | Rubber is cured inside a fixed metal tube under heat and pressure. |

| Product Uniformity | Ensures uniform thickness and shape due to even bladder expansion. | May have uneven thickness as rubber conforms to tube shape. |

| Equipment Cost | Higher due to specialized bladder apparatus. | Lower; uses simple metal tubes. |

| Cycle Time | Typically shorter due to efficient heat and pressure application. | Longer curing cycles required. |

| Applications | Automotive hoses, complex rubber parts demanding precise shapes. | Simple rubber tubing, sleeves, and cylindrical parts. |

| Advantages | Better dimensional control, improved quality, less waste. | Cost-effective for bulk production, simpler setup. |

| Limitations | Higher initial investment, bladder maintenance needed. | Possible shape inconsistencies, less control on thickness. |

Introduction to Bladder Curing and Tube Curing

Bladder curing and tube curing are two prominent methods used in food processing to preserve and enhance the flavor of sausages and cured meats. Bladder curing involves filling a flexible bladder with curing ingredients and placing it inside the meat, enabling even distribution of flavors and moisture. Tube curing uses pre-made tubes filled with curing solution to encase the meat, offering efficiency and consistency in industrial production.

Definition and Process Overview

Bladder curing involves inflating a bladder inside a casing to evenly press the meat during the curing process, promoting uniform texture and flavor penetration. Tube curing uses a hollow tube inserted into the meat, allowing curing agents to diffuse directly through the inner surfaces, ensuring thorough preservation and enhanced taste. Your choice between bladder or tube curing impacts the final product's consistency and curing efficiency.

Key Differences Between Bladder Curing and Tube Curing

Bladder curing involves inflating a bladder inside the sausage casing, allowing for even pressure distribution and uniform shape, while tube curing uses a rigid tube to form the sausage, often resulting in a firmer texture. Bladder curing provides better control over the sausage's diameter and reduces casing tension, enhancing the final product's quality. Your choice depends on desired texture and consistency, with bladder curing favored for delicate, evenly shaped sausages and tube curing suited for denser, firmer varieties.

Historical Development of Curing Techniques

Bladder curing and tube curing represent key developments in the historical evolution of meat preservation techniques, with bladder curing dating back to ancient times when natural animal membranes were used to encase and cure meats. Tube curing emerged as a more modern innovation, utilizing synthetic materials that allow for greater control over humidity and airflow during the curing process, enhancing consistency and safety. Understanding these methods can help you appreciate how curing technology has advanced to improve flavor and preservation in contemporary charcuterie.

Advantages of Bladder Curing

Bladder curing offers superior uniformity in tire shape and tread profile, resulting in enhanced performance and extended tire life. Its precise control over pressure and temperature ensures consistent curing, reducing defects and improving overall quality. You benefit from increased production efficiency and reduced material waste compared to traditional tube curing methods.

Advantages of Tube Curing

Tube curing offers enhanced uniformity in temperature distribution, which results in more consistent product quality compared to bladder curing. The method reduces the risk of uneven expansion and potential defects, improving overall durability and structural integrity. Additionally, tube curing increases efficiency in processing time and energy consumption, leading to cost savings in industrial applications.

Applications in Tire Manufacturing

Bladder curing is predominantly used in high-performance tire manufacturing due to its ability to apply uniform pressure and heat, resulting in consistent tread patterns and superior rubber bonding. Tube curing, on the other hand, is commonly employed in smaller-scale or specialized tire production where cost-effectiveness and flexibility in curing different tire sizes are critical. Both methods are integral to optimizing vulcanization processes, but bladder curing better suits mass production of standard passenger and commercial vehicle tires.

Quality and Performance Outcomes

Bladder curing offers superior uniformity in tire sidewall shaping, resulting in enhanced structural integrity and improved overall tire performance compared to tube curing. Tube curing demonstrates slower heat transfer rates, which can cause uneven vulcanization and variable product quality. High-quality finish and consistent mechanical properties make bladder curing the preferred method in modern tire manufacturing.

Energy Efficiency and Environmental Impact

Bladder curing offers superior energy efficiency by using precise heat application and reduced curing times compared to tube curing, which relies on longer, less controlled heat exposure. The environmental impact of bladder curing is minimized due to lower fuel consumption and reduced greenhouse gas emissions, whereas tube curing typically generates higher emissions because of extended heating processes. Bladder curing also supports sustainability efforts by enabling more uniform curing with less waste, contributing to eco-friendly production practices in tire manufacturing.

Choosing the Right Curing Method

Choosing the right curing method between bladder curing and tube curing depends on the product type and desired quality outcomes. Bladder curing offers uniform heat distribution and preservation of casing shape, ideal for whole-muscle products like sausages and hams, while tube curing is better suited for larger cuts requiring slower, controlled curing to enhance flavor development. Understanding the specific requirements of the meat product and production scale is essential to optimize texture, taste, and shelf life.

Bladder Curing vs Tube Curing Infographic

libmatt.com

libmatt.com