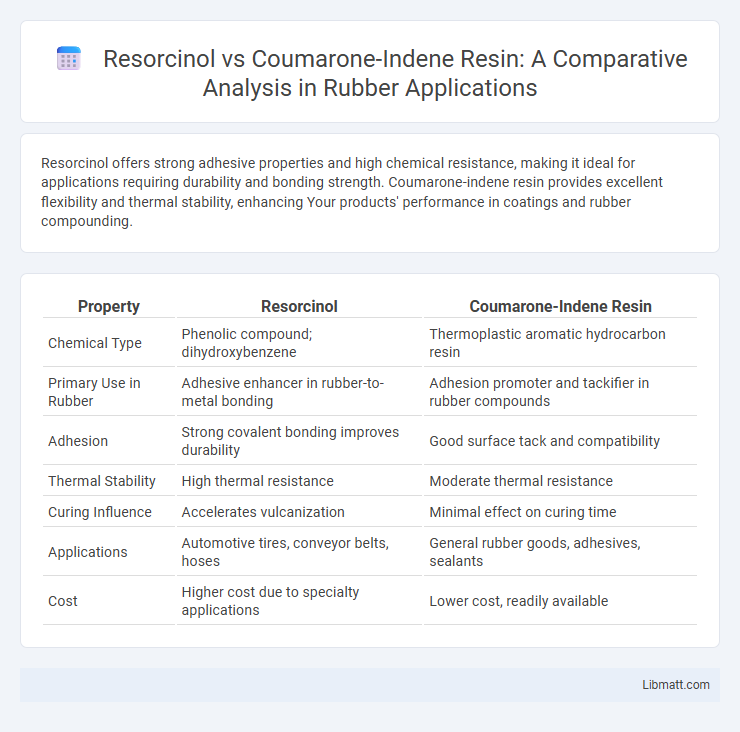

Resorcinol offers strong adhesive properties and high chemical resistance, making it ideal for applications requiring durability and bonding strength. Coumarone-indene resin provides excellent flexibility and thermal stability, enhancing Your products' performance in coatings and rubber compounding.

Table of Comparison

| Property | Resorcinol | Coumarone-Indene Resin |

|---|---|---|

| Chemical Type | Phenolic compound; dihydroxybenzene | Thermoplastic aromatic hydrocarbon resin |

| Primary Use in Rubber | Adhesive enhancer in rubber-to-metal bonding | Adhesion promoter and tackifier in rubber compounds |

| Adhesion | Strong covalent bonding improves durability | Good surface tack and compatibility |

| Thermal Stability | High thermal resistance | Moderate thermal resistance |

| Curing Influence | Accelerates vulcanization | Minimal effect on curing time |

| Applications | Automotive tires, conveyor belts, hoses | General rubber goods, adhesives, sealants |

| Cost | Higher cost due to specialty applications | Lower cost, readily available |

Introduction to Resorcinol and Coumarone-indene Resin

Resorcinol is an organic compound widely used as a cross-linking agent in adhesives and composites, known for its excellent bonding properties and chemical resistance. Coumarone-indene resin, a thermoplastic resin derived from coal tar, is valued for its high hardness, chemical stability, and strong adhesive performance in coatings and rubber applications. Both materials play critical roles in industrial manufacturing, offering distinct advantages based on their chemical structures and functional properties.

Chemical Structure and Composition

Resorcinol is a dihydroxybenzene compound characterized by two hydroxyl groups positioned meta to each other on a benzene ring, contributing to its high reactivity and strong adhesive properties. Coumarone-indene resin is a complex mixture derived from the polymerization of coumarone and indene monomers, consisting primarily of fused aromatic rings with branched alkyl chains, which imparts rigidity and thermal stability. The distinct chemical structures--simple dihydroxybenzene in resorcinol versus polycyclic aromatic hydrocarbons in coumarone-indene resin--result in differing solubility, adhesion, and polymer interaction profiles.

Manufacturing Process Comparison

Resorcinol is synthesized through the reaction of resorcinol with formaldehyde under acidic or basic conditions, forming strong, water-resistant adhesives primarily used in plywood and rubber applications. Coumarone-indene resin is produced via the polymerization of coumarone and indene monomers obtained from coal tar, resulting in a hard, thermoplastic resin commonly applied in coatings, adhesives, and printing inks. Your choice between these resins depends on the required adhesive strength, thermal stability, and specific application, influenced directly by their distinct manufacturing methods.

Physical Properties Overview

Resorcinol exhibits high solubility in water, strong adhesive properties, and exceptional chemical resistance, making it ideal for durable bonding applications. Coumarone-indene resin features excellent thermoplastic properties with high hardness and flexibility, providing superior impact resistance and moisture stability. Your choice between these resins depends on whether high chemical resistance or thermoplastic versatility is more critical for your application.

Thermal Stability and Resistance

Resorcinol exhibits superior thermal stability, maintaining its structural integrity at high temperatures, making it ideal for applications requiring heat resistance. Coumarone-indene resin offers moderate thermal resistance but tends to degrade faster under prolonged heat exposure compared to resorcinol. Your choice between these resins should consider the specific temperature ranges and durability requirements of your project.

Adhesion and Bonding Capabilities

Resorcinol offers superior adhesion and bonding capabilities, especially in wood and rubber applications, due to its strong chemical affinity and ability to form durable, water-resistant bonds. Coumarone-indene resin provides excellent bonding strength in coatings and adhesives, with high resistance to heat and chemicals, but generally falls short of the long-term durability seen with resorcinol-based adhesives. Understanding the differences in your project requirements can help you choose the optimal resin for maximum bonding performance.

Key Industrial Applications

Resorcinol is prominently used in the production of adhesives, especially for rubber and tire manufacturing, as well as in wood glues and coatings due to its strong bonding and resistance to heat and chemicals. Coumarone-indene resin finds key applications in road marking paints, printing inks, and rubber compounding, providing excellent hardness, gloss, and water resistance. Your choice between these resins depends on the specific industrial needs for durability, adhesion, and environmental exposure.

Environmental Impact and Safety

Resorcinol demonstrates moderate environmental persistence with low bioaccumulation potential, but its toxicity to aquatic organisms necessitates controlled industrial use and proper waste management. Coumarone-indene resin, derived from coal tar, poses higher environmental risks due to the presence of polycyclic aromatic hydrocarbons (PAHs), which are carcinogenic and contribute to soil and water contamination. Safety precautions for handling coumarone-indene resins include protective equipment and adequate ventilation to minimize exposure to hazardous fumes and dust, while resorcinol requires safe handling to prevent skin sensitization and respiratory irritation.

Cost Efficiency and Availability

Resorcinol typically offers moderate cost efficiency with widespread availability in industrial markets, making it a reliable choice for adhesives and coatings. Coumarone-indene resin often provides higher cost efficiency due to lower production costs and easier sourcing, especially in regions with abundant coal tar derivatives. Your selection between these resins should consider local supply chains and budget constraints to optimize overall production expenses.

Summary: Choosing the Right Resin

Resorcinol offers exceptional bonding strength and chemical resistance, making it ideal for high-performance adhesives in woodworking and metal repairs. Coumarone-indene resin provides excellent water resistance and flexibility, suitable for coatings, ink formulations, and rubber compounding. Selecting the right resin depends on specific application requirements such as durability, environmental exposure, and mechanical stress tolerance.

Resorcinol vs Coumarone-indene Resin Infographic

libmatt.com

libmatt.com