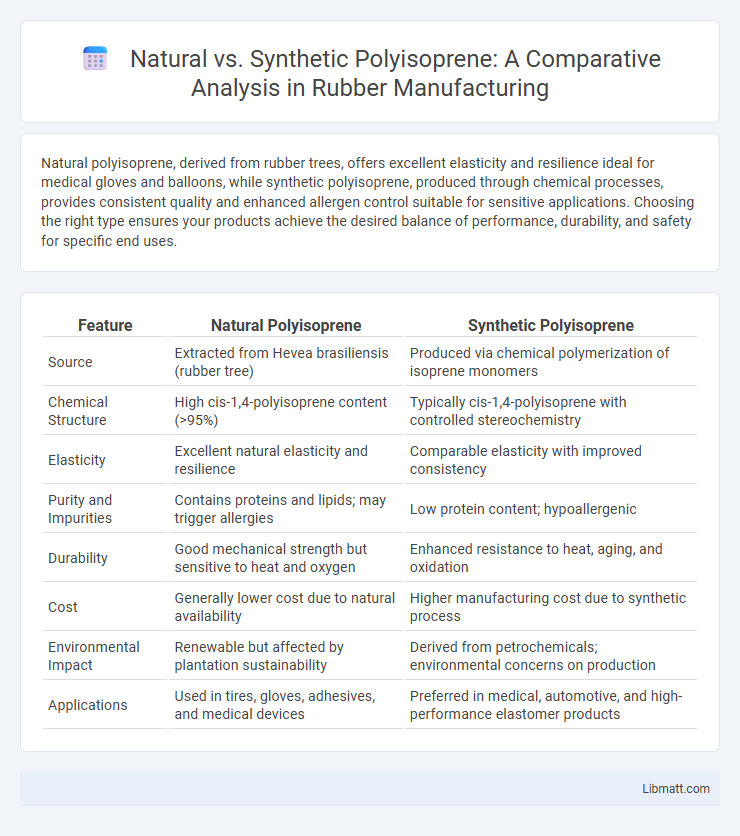

Natural polyisoprene, derived from rubber trees, offers excellent elasticity and resilience ideal for medical gloves and balloons, while synthetic polyisoprene, produced through chemical processes, provides consistent quality and enhanced allergen control suitable for sensitive applications. Choosing the right type ensures your products achieve the desired balance of performance, durability, and safety for specific end uses.

Table of Comparison

| Feature | Natural Polyisoprene | Synthetic Polyisoprene |

|---|---|---|

| Source | Extracted from Hevea brasiliensis (rubber tree) | Produced via chemical polymerization of isoprene monomers |

| Chemical Structure | High cis-1,4-polyisoprene content (>95%) | Typically cis-1,4-polyisoprene with controlled stereochemistry |

| Elasticity | Excellent natural elasticity and resilience | Comparable elasticity with improved consistency |

| Purity and Impurities | Contains proteins and lipids; may trigger allergies | Low protein content; hypoallergenic |

| Durability | Good mechanical strength but sensitive to heat and oxygen | Enhanced resistance to heat, aging, and oxidation |

| Cost | Generally lower cost due to natural availability | Higher manufacturing cost due to synthetic process |

| Environmental Impact | Renewable but affected by plantation sustainability | Derived from petrochemicals; environmental concerns on production |

| Applications | Used in tires, gloves, adhesives, and medical devices | Preferred in medical, automotive, and high-performance elastomer products |

Introduction to Polyisoprene

Polyisoprene, a versatile polymer, exists in two primary forms: natural and synthetic, each with distinct properties and applications. Natural polyisoprene is derived from latex extracted from rubber trees, known for its superior elasticity, resilience, and biodegradability. Synthetic polyisoprene, produced through chemical polymerization, offers consistent quality, enhanced purity, and tailored physical characteristics for industrial uses.

Chemical Structure and Sources

Natural polyisoprene is primarily sourced from the latex of the Hevea brasiliensis tree and consists mostly of cis-1,4-polyisoprene, giving it excellent elasticity and resilience. Synthetic polyisoprene is chemically engineered through the polymerization of isoprene monomers, allowing control over its microstructure but often resulting in a slightly different arrangement, such as varying cis-trans configurations. Your choice between natural and synthetic polyisoprene depends on the desired chemical properties and application requirements.

Overview of Natural Polyisoprene

Natural polyisoprene is a polymer derived primarily from the latex of rubber trees (Hevea brasiliensis), known for its excellent elasticity, tensile strength, and resilience. This biopolymer is widely used in the production of high-performance products such as medical gloves, tires, and adhesives due to its superior biodegradability and low allergenic potential compared to synthetic alternatives. Understanding the benefits of natural polyisoprene can help you select materials that balance durability with environmental sustainability.

Overview of Synthetic Polyisoprene

Synthetic polyisoprene is a man-made polymer designed to mimic the properties of natural polyisoprene but with enhanced consistency and purity. Produced through the polymerization of isoprene derived from petroleum, it offers superior resistance to aging, chemicals, and environmental factors compared to its natural counterpart. Your applications benefit from synthetic polyisoprene's predictable performance and reduced allergenic potential, making it ideal for medical, automotive, and industrial uses.

Production Processes: Natural vs Synthetic

Natural polyisoprene is produced through the harvesting of latex from rubber trees (Hevea brasiliensis), involving tapping the tree bark to extract the milky fluid that undergoes coagulation and drying. Synthetic polyisoprene is manufactured via chemical polymerization of isoprene monomers, typically using catalysts in controlled industrial reactors to mimic the molecular structure of natural rubber. Understanding these distinct production processes helps you select the appropriate type based on availability, cost, and performance requirements.

Physical and Mechanical Properties Comparison

Natural polyisoprene offers superior elasticity, tensile strength, and abrasion resistance compared to its synthetic counterpart, making it ideal for applications requiring high durability. Synthetic polyisoprene typically provides more consistent quality and enhanced aging resistance due to controlled polymerization processes. Understanding these physical and mechanical property differences helps you select the most suitable polyisoprene type for your specific performance needs.

Environmental Impact and Sustainability

Natural polyisoprene, derived from rubber trees, offers a renewable and biodegradable alternative with a lower carbon footprint compared to synthetic variants produced from petrochemicals. Synthetic polyisoprene's reliance on fossil fuels contributes to higher greenhouse gas emissions and environmental pollution during manufacturing and disposal. Choosing natural polyisoprene can reduce your ecological impact, supporting sustainability through responsible sourcing and biodegradability.

Typical Applications and Uses

Natural polyisoprene is predominantly used in medical gloves, condoms, and adhesives due to its excellent elasticity, resilience, and biocompatibility. Synthetic polyisoprene offers consistent quality and purity, making it suitable for high-performance tires, footwear, and industrial rubber goods where chemical resistance and durability are critical. Both materials serve distinct markets, with natural polyisoprene favored for medical and hygiene applications and synthetic variants preferred in automotive and manufacturing industries.

Cost and Availability Considerations

Natural polyisoprene is often more expensive due to its reliance on rubber tree cultivation and seasonal harvesting, which can limit availability and increase costs. Synthetic polyisoprene, produced through petrochemical processes, offers more consistent supply and lower price volatility, making it a cost-effective option for large-scale manufacturing. You should weigh the trade-offs between natural origin and budget constraints when selecting the appropriate polyisoprene type for your application.

Choosing Between Natural and Synthetic Polyisoprene

Choosing between natural and synthetic polyisoprene depends on the specific application requirements; natural polyisoprene offers superior elasticity, resilience, and biodegradability, making it ideal for medical gloves and high-performance tires. Synthetic polyisoprene provides consistent quality, chemical resistance, and longer shelf life, suited for products demanding controlled properties such as adhesives and rubber bands. Cost considerations and allergy concerns also influence the decision, with synthetic variants favored in environments requiring hypoallergenic materials.

Natural vs Synthetic Polyisoprene Infographic

libmatt.com

libmatt.com