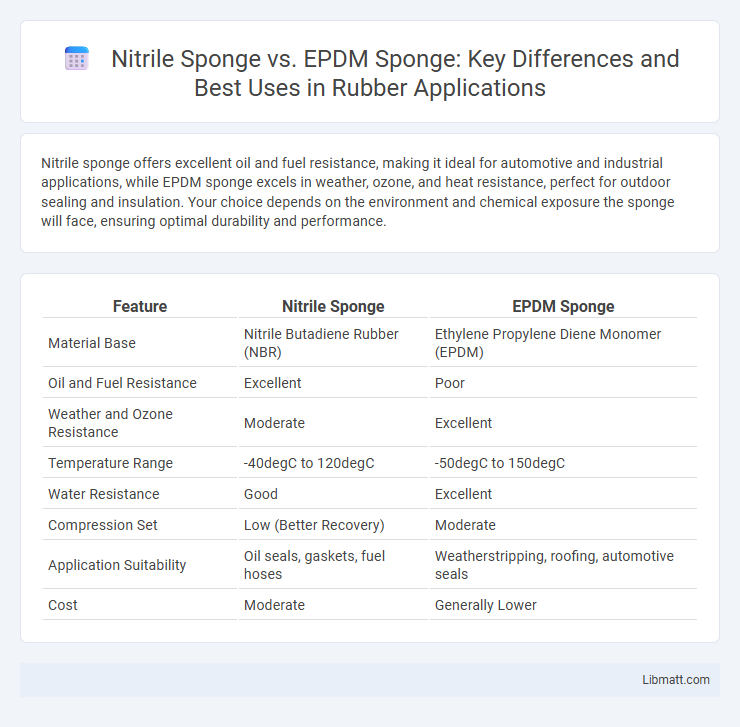

Nitrile sponge offers excellent oil and fuel resistance, making it ideal for automotive and industrial applications, while EPDM sponge excels in weather, ozone, and heat resistance, perfect for outdoor sealing and insulation. Your choice depends on the environment and chemical exposure the sponge will face, ensuring optimal durability and performance.

Table of Comparison

| Feature | Nitrile Sponge | EPDM Sponge |

|---|---|---|

| Material Base | Nitrile Butadiene Rubber (NBR) | Ethylene Propylene Diene Monomer (EPDM) |

| Oil and Fuel Resistance | Excellent | Poor |

| Weather and Ozone Resistance | Moderate | Excellent |

| Temperature Range | -40degC to 120degC | -50degC to 150degC |

| Water Resistance | Good | Excellent |

| Compression Set | Low (Better Recovery) | Moderate |

| Application Suitability | Oil seals, gaskets, fuel hoses | Weatherstripping, roofing, automotive seals |

| Cost | Moderate | Generally Lower |

Introduction to Nitrile and EPDM Sponges

Nitrile sponge is a synthetic rubber known for its excellent resistance to oil, fuel, and chemicals, making it ideal for automotive and industrial sealing applications. EPDM sponge, composed of ethylene propylene diene monomer rubber, excels in weather, ozone, and heat resistance, commonly used in outdoor and roofing seals. Both materials offer unique durability and flexibility suited to specific environmental and mechanical conditions.

Chemical Composition and Structure

Nitrile sponge, composed primarily of acrylonitrile and butadiene copolymers, offers excellent resistance to oils, fuels, and chemicals due to its dense molecular structure rich in nitrile groups. EPDM sponge, made from ethylene propylene diene monomer rubber, features a saturated synthetic polymer chain with excellent resistance to weathering, ozone, and polar solvents but lower compatibility with petroleum-based chemicals. Your choice between nitrile and EPDM sponge depends on the chemical environment and structural properties required for optimal performance.

Key Physical Properties Compared

Nitrile sponge offers excellent oil, fuel, and chemical resistance with strong compression set properties, making it ideal for industrial sealing applications. EPDM sponge excels in weather, ozone, and heat resistance, providing superior durability for outdoor and automotive uses. Your choice depends on specific environmental exposure and mechanical requirements, as both materials deliver distinct performance advantages.

Resistance to Oils and Chemicals

Nitrile sponge offers superior resistance to oils, fuels, and petroleum-based chemicals, making it ideal for environments with frequent exposure to such substances. EPDM sponge excels in resisting weathering, ozone, and a broad range of chemicals but performs poorly against oils and hydrocarbons. Your choice should align with the specific chemical exposure requirements to ensure optimal durability and performance.

Performance in Extreme Temperatures

Nitrile sponge offers excellent resistance to extreme temperatures, typically ranging from -30degC to 120degC, making it ideal for applications exposed to oil, fuel, and other harsh chemicals. EPDM sponge withstands a broader temperature range, from -50degC to 150degC, while providing superior resistance to heat, ozone, and weathering, which is crucial for outdoor and automotive uses. Understanding your specific temperature requirements will help you choose the best material for reliable sealing and insulation performance.

Water and Weather Resistance Differences

Nitrile sponge offers superior water resistance due to its oil and chemical-resistant properties, making it ideal for applications exposed to moisture and harsh environments. EPDM sponge excels in weather resistance, providing excellent protection against UV rays, ozone, and extreme temperatures, which enhances durability in outdoor settings. The choice between nitrile and EPDM sponges depends on the specific environmental challenges, with nitrile favored for water and oil exposure, and EPDM preferred for prolonged weather exposure.

Common Industrial and Commercial Applications

Nitrile sponge is widely used in automotive, oil and gas, and chemical processing industries due to its excellent resistance to oil, fuel, and chemicals, making it ideal for gaskets, seals, and insulation applications. EPDM sponge excels in building construction, HVAC systems, and weatherstripping because of its superior resistance to weather, ozone, and UV radiation, providing effective sealing and thermal insulation. Both materials serve crucial roles in manufacturing automotive parts, industrial equipment, and commercial appliances where durability and environmental resistance are essential.

Cost and Availability Analysis

Nitrile sponge offers a cost-effective solution with moderate pricing and widespread availability due to its common usage in oil-resistant applications. EPDM sponge, though generally priced higher, provides superior weather and ozone resistance but may have limited availability in certain regions compared to nitrile. Your choice depends on balancing budget constraints with the specific environmental durability requirements of your project.

Environmental Impact and Safety

Nitrile Sponge, made from synthetic rubber, offers superior resistance to oil and chemicals but can have a higher environmental impact due to slower biodegradability and reliance on petrochemicals. EPDM Sponge is more environmentally friendly, as it decomposes more readily and exhibits excellent weathering resistance without releasing harmful substances, making it safer for applications involving prolonged human contact. Your choice between these materials should consider both the operational safety needs and the environmental footprint relevant to your project.

Choosing the Right Sponge Material for Your Project

Nitrile sponge offers excellent resistance to oils, fuels, and chemicals, making it ideal for automotive and industrial sealing applications. EPDM sponge excels in weather, ozone, and heat resistance, suitable for outdoor and HVAC projects. Selecting the right sponge material depends on the specific environmental conditions and chemical exposure your project demands.

Nitrile Sponge vs EPDM Sponge Infographic

libmatt.com

libmatt.com