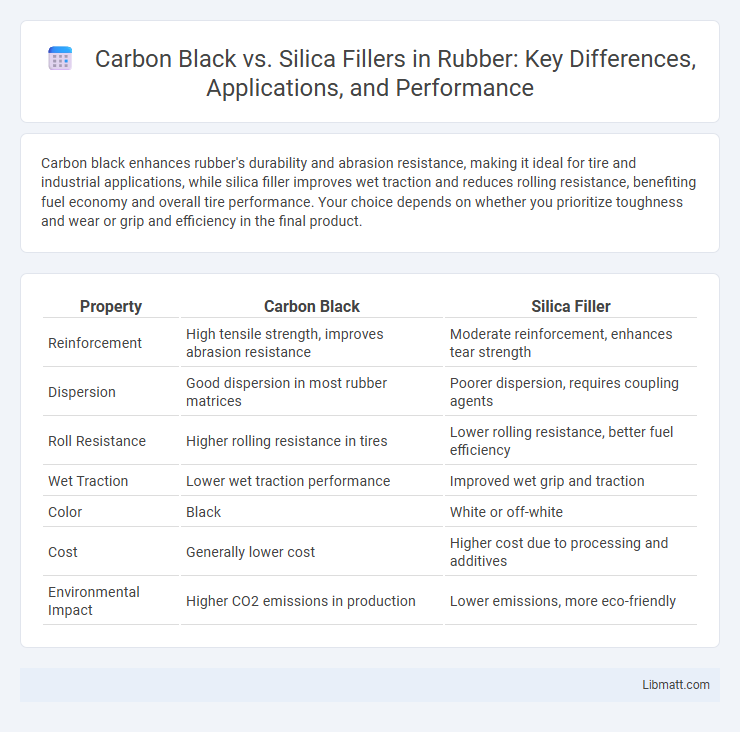

Carbon black enhances rubber's durability and abrasion resistance, making it ideal for tire and industrial applications, while silica filler improves wet traction and reduces rolling resistance, benefiting fuel economy and overall tire performance. Your choice depends on whether you prioritize toughness and wear or grip and efficiency in the final product.

Table of Comparison

| Property | Carbon Black | Silica Filler |

|---|---|---|

| Reinforcement | High tensile strength, improves abrasion resistance | Moderate reinforcement, enhances tear strength |

| Dispersion | Good dispersion in most rubber matrices | Poorer dispersion, requires coupling agents |

| Roll Resistance | Higher rolling resistance in tires | Lower rolling resistance, better fuel efficiency |

| Wet Traction | Lower wet traction performance | Improved wet grip and traction |

| Color | Black | White or off-white |

| Cost | Generally lower cost | Higher cost due to processing and additives |

| Environmental Impact | Higher CO2 emissions in production | Lower emissions, more eco-friendly |

Introduction to Fillers in Rubber Compounds

Carbon black and silica are essential fillers in rubber compounds, enhancing mechanical properties and durability. Carbon black improves tensile strength, abrasion resistance, and conductivity, making it ideal for tires and heavy-duty applications. Silica, favored for low rolling resistance and improved wet traction, is widely used in fuel-efficient tires and eco-friendly rubber products.

What is Carbon Black?

Carbon black is a fine black powder produced by the incomplete combustion of heavy petroleum products, primarily used as a reinforcing filler in rubber and plastics to enhance durability and wear resistance. Compared to silica filler, carbon black provides superior conductivity, UV protection, and improved tensile strength, making it essential in tire manufacturing and industrial applications. Your choice between carbon black and silica depends on desired mechanical properties, cost, and application requirements.

What is Silica Filler?

Silica filler is a fine, powdered mineral derived from silicon dioxide used to enhance the mechanical properties and durability of rubber and plastic products. It improves abrasion resistance, tensile strength, and reduces rolling resistance in tires, contributing to better fuel efficiency and longer wear life. You can choose silica filler over carbon black when seeking enhanced performance in applications requiring lower heat buildup and improved wet traction.

Key Differences Between Carbon Black and Silica

Carbon Black and Silica differ primarily in their chemical composition and reinforcing properties; Carbon Black, a carbon-based filler, enhances abrasion resistance and conductivity, while Silica, a silicon dioxide compound, improves tear strength and reduces rolling resistance in rubber products. The particle size and surface energy of Silica promote better interaction with polar elastomers, resulting in improved fuel efficiency and wet traction in tires, compared to Carbon Black's superior durability and UV protection. Your choice between these fillers depends on the desired mechanical performance and application, with Carbon Black favored for heavy-duty uses and Silica preferred for high-performance, eco-friendly solutions.

Performance Impact: Carbon Black vs. Silica

Carbon black significantly enhances tensile strength, abrasion resistance, and electrical conductivity in rubber compounds, making it ideal for automotive tires and industrial applications. Silica fillers improve wet traction, rolling resistance, and fuel efficiency due to their ability to reinforce tire tread with lower hysteresis losses. The choice between carbon black and silica filler directly influences durability, grip, and overall performance characteristics of rubber products in various environments.

Environmental Considerations and Sustainability

Carbon black production generates significant CO2 emissions and relies heavily on fossil fuels, raising environmental concerns, whereas silica filler is derived from abundant natural sand and offers a lower carbon footprint. Silica fillers improve tire fuel efficiency by reducing rolling resistance, contributing to lower greenhouse gas emissions during use. The shift towards silica fillers aligns with sustainability goals, promoting eco-friendly tire manufacturing and enhanced recyclability compared to traditional carbon black.

Cost Analysis: Carbon Black and Silica Fillers

Carbon Black typically offers a lower cost per unit compared to Silica fillers, making it a budget-friendly option for rubber and tire manufacturing. Silica fillers often incur higher upfront costs but provide enhanced performance benefits such as improved fuel efficiency and reduced rolling resistance. Your choice between Carbon Black and Silica will depend on balancing cost constraints with desired product durability and performance characteristics.

Applications in the Tire Industry

Carbon black serves as a primary reinforcing filler in tire manufacturing, providing superior abrasion resistance, enhanced tensile strength, and improved rolling resistance, which contributes to better fuel efficiency. Silica filler is increasingly used in tire treads to reduce rolling resistance and enhance wet traction, optimizing fuel economy and safety performance. Combining carbon black and silica fillers in tire compounds balances durability with improved grip and low rolling resistance, meeting stringent industry standards for performance and environmental impact.

Processing and Compatibility with Polymers

Carbon black offers superior compatibility with nonpolar polymers such as natural rubber and styrene-butadiene rubber, enhancing reinforcement and electrical conductivity during processing. Silica filler tends to provide better interaction with polar polymers like nitrile rubber and ethylene-propylene-diene monomer (EPDM), improving mechanical properties and wet traction performance. Your choice between carbon black and silica filler should consider the specific polymer matrix and desired processing characteristics for optimal composite performance.

Future Trends in Filler Technology

Advancements in filler technology are driving a shift towards hybrid systems combining carbon black and silica to enhance tire performance and sustainability. Research emphasizes nano-sized silica particles and surface treatments that improve dispersion and reinforce rubber matrices without compromising durability. Emerging trends prioritize eco-friendly fillers with reduced environmental impact while maintaining or exceeding the mechanical properties provided by traditional carbon black.

Carbon Black vs Silica Filler Infographic

libmatt.com

libmatt.com