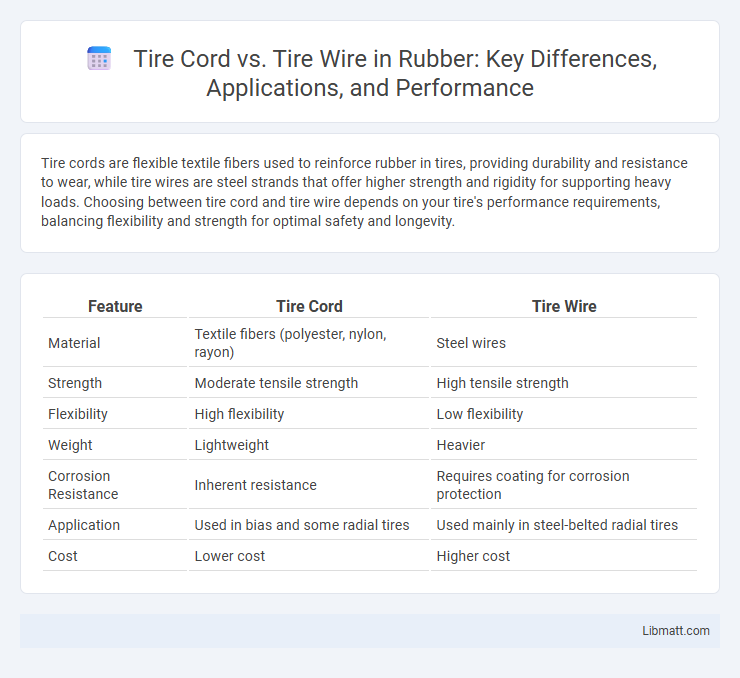

Tire cords are flexible textile fibers used to reinforce rubber in tires, providing durability and resistance to wear, while tire wires are steel strands that offer higher strength and rigidity for supporting heavy loads. Choosing between tire cord and tire wire depends on your tire's performance requirements, balancing flexibility and strength for optimal safety and longevity.

Table of Comparison

| Feature | Tire Cord | Tire Wire |

|---|---|---|

| Material | Textile fibers (polyester, nylon, rayon) | Steel wires |

| Strength | Moderate tensile strength | High tensile strength |

| Flexibility | High flexibility | Low flexibility |

| Weight | Lightweight | Heavier |

| Corrosion Resistance | Inherent resistance | Requires coating for corrosion protection |

| Application | Used in bias and some radial tires | Used mainly in steel-belted radial tires |

| Cost | Lower cost | Higher cost |

Introduction to Tire Cord and Tire Wire

Tire cord consists of high-strength textile fibers, such as polyester, nylon, or rayon, woven into fabric to provide flexibility and reinforcement within the tire structure. Tire wire, in contrast, refers to steel wire used primarily in the tire bead and belt areas to enhance rigidity, durability, and load-bearing capacity. Both materials play critical roles in tire performance by balancing elasticity and strength for optimal safety and longevity.

What is Tire Cord?

Tire cord is a high-strength textile fiber used as the reinforcing material inside tires, providing flexibility and durability to withstand road stress. It is typically made from materials like polyester, nylon, or rayon, which enhance the tire's performance by improving its resistance to tension and deformation. Your tires rely on tire cords to maintain structural integrity and ensure safety during driving.

What is Tire Wire?

Tire wire is a high-tensile steel wire used in the reinforcement of tires, providing structural strength and durability essential for vehicle safety. It differs from tire cord in its manufacturing process and physical properties, typically being thicker and used in bead wires or tire belt edge reinforcements. The primary function of tire wire is to maintain the tire's shape under stress and prevent deformation during operation, ensuring consistent performance and longevity.

Material Composition Comparison

Tire cord typically consists of high-strength synthetic fibers such as polyester, nylon, or aramid, offering flexibility and durability to reinforce tires. Tire wire, on the other hand, is made from steel wires that provide superior tensile strength and resistance to heat, enhancing the tire's structural integrity. Understanding the material composition differences helps you select the right reinforcement for specific tire performance and durability requirements.

Manufacturing Processes

Tire cords are manufactured using high-strength polyester, rayon, or nylon fibers woven into fabric before being coated with rubber to provide flexibility and durability. Tire wires consist of steel filaments twisted and heat-treated to enhance tensile strength and corrosion resistance, making them ideal for reinforcing tire belts. The key difference lies in tire cords being textile-based with rubber impregnation, while tire wires are metallic, requiring precise wire drawing and heat treatment processes.

Strength and Durability Differences

Tire cords, typically made of textile fibers such as polyester or nylon, offer excellent flexibility and moderate strength, enhancing tire comfort and wear resistance. Tire wires, composed of high-tensile steel, provide superior strength and durability, enabling the tire to withstand heavy loads and high pressure without deformation. The primary difference lies in the tensile strength and longevity, with steel tire wire outperforming textile tire cord in heavy-duty applications requiring maximum durability.

Applications in the Tire Industry

Tire cord and tire wire serve crucial roles in the tire industry, with tire cords primarily used as reinforcement materials in the carcass and belts of radial and bias tires, enhancing strength and flexibility. Tire wire, typically made of high-strength steel, is utilized in bead wire applications to provide firm anchoring of the tire to the rim, ensuring stability and durability under high pressure and load conditions. The integration of these components improves overall tire performance, including wear resistance, structural integrity, and safety in automotive and heavy-duty vehicle tires.

Performance Impact on Tires

Tire cord and tire wire both significantly influence tire durability and driving safety, with tire cord providing enhanced flexibility and tensile strength that improves overall performance under dynamic stresses. Tire cord's high tensile strength allows for better resistance to wear and deformation, leading to longer tire life and improved handling, especially in high-speed and heavy-load conditions. In contrast, tire wire tends to be stiffer, which can contribute to increased rigidity but may reduce comfort and increase the risk of premature tire failure under extreme stress.

Environmental Considerations

Tire cord and tire wire differ significantly in their environmental impacts due to material composition and production processes; tire cord, often made from synthetic fibers like polyester or nylon, tends to have a lower carbon footprint compared to tire wire, which is typically steel-based with higher energy consumption during manufacturing. Recycling tire wire is more challenging due to its metallic nature, whereas tire cord, being textile-based, offers improved opportunities for reuse and incorporation into secondary products. Selecting tire cord over tire wire can contribute to reduced landfill waste and lower emissions in tire production and disposal stages.

Choosing Between Tire Cord and Tire Wire

Choosing between tire cord and tire wire depends on specific tire performance requirements, as tire cords offer flexibility and lightweight strength ideal for passenger vehicles, while tire wires provide superior rigidity and durability suited for heavy-duty tires. Tire cord, typically made of polyester or rayon fibers, enhances tire elasticity and reduces rolling resistance, whereas tire wire, usually composed of steel, excels in reinforcing tire structure and increasing load capacity. Evaluating the intended use, load demands, and tire design specifications ensures the optimal choice between tire cord and tire wire for safety and longevity.

Tire Cord vs Tire Wire Infographic

libmatt.com

libmatt.com