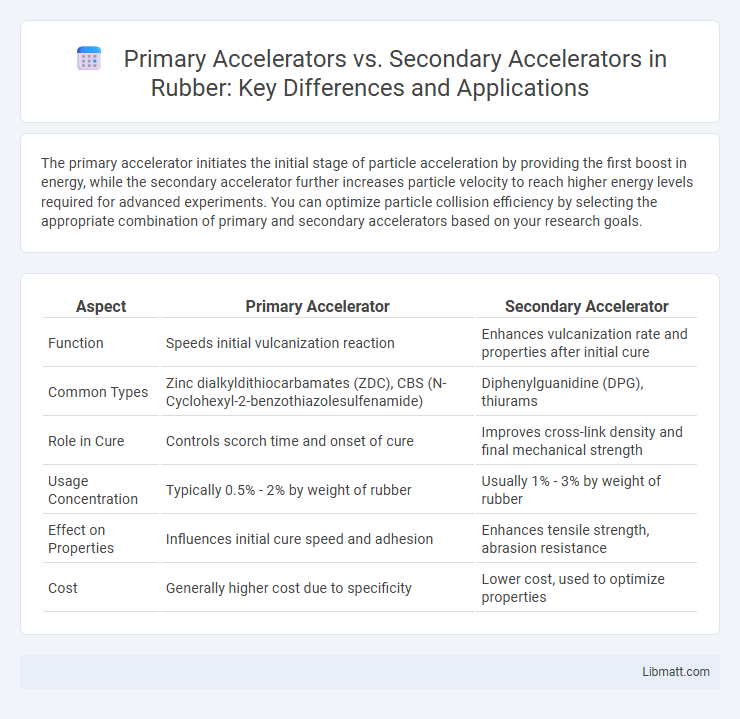

The primary accelerator initiates the initial stage of particle acceleration by providing the first boost in energy, while the secondary accelerator further increases particle velocity to reach higher energy levels required for advanced experiments. You can optimize particle collision efficiency by selecting the appropriate combination of primary and secondary accelerators based on your research goals.

Table of Comparison

| Aspect | Primary Accelerator | Secondary Accelerator |

|---|---|---|

| Function | Speeds initial vulcanization reaction | Enhances vulcanization rate and properties after initial cure |

| Common Types | Zinc dialkyldithiocarbamates (ZDC), CBS (N-Cyclohexyl-2-benzothiazolesulfenamide) | Diphenylguanidine (DPG), thiurams |

| Role in Cure | Controls scorch time and onset of cure | Improves cross-link density and final mechanical strength |

| Usage Concentration | Typically 0.5% - 2% by weight of rubber | Usually 1% - 3% by weight of rubber |

| Effect on Properties | Influences initial cure speed and adhesion | Enhances tensile strength, abrasion resistance |

| Cost | Generally higher cost due to specificity | Lower cost, used to optimize properties |

Understanding Accelerators: Primary vs Secondary

Primary accelerators provide the initial, intense acceleration stage in particle physics experiments, directly increasing particle energy to relativistic speeds. Secondary accelerators receive particle beams from primary accelerators to further boost energy levels or prepare particles for collision or experimentation. Understanding the distinct roles and energy transfer mechanisms of primary and secondary accelerators is crucial for optimizing particle acceleration processes and experimental outcomes.

Key Definitions: What are Primary and Secondary Accelerators?

Primary accelerators are organizations or programs that provide early-stage startups with intensive mentorship, seed funding, and access to a network of investors to accelerate business growth. Secondary accelerators support startups that have already undergone initial acceleration, offering advanced resources, market expansion strategies, and follow-on funding opportunities. Both types play crucial roles in different phases of the startup lifecycle, ensuring continuous development from inception to scaling.

Chemical Structure Differences

Primary accelerators, such as mercaptobenzothiazole (MBT), contain reactive sulfur and nitrogen atoms that facilitate rapid vulcanization of rubber by forming strong cross-links. Secondary accelerators, like thiazoles or sulfenamides, have more complex molecular structures designed to work synergistically with primary accelerators, enhancing vulcanization speed and improving physical properties. Your choice between these accelerators depends on their chemical compatibility and the desired balance between processing efficiency and rubber performance.

Mechanisms of Action in Vulcanization

Primary accelerators in vulcanization, such as sulfenamides and thiurams, enhance the formation of sulfur cross-links by promoting the initial reaction between sulfur and rubber chains, resulting in faster curing times and improved mechanical properties. Secondary accelerators like thioureas and dithiocarbamates synergistically boost the efficiency of primary accelerators by facilitating the breakdown of sulfur-sulfur bonds, thereby increasing cross-link density and elasticity. Understanding the distinct mechanisms of action in your rubber formulation helps optimize vulcanization speed and final product performance.

Typical Applications of Primary Accelerators

Primary accelerators are commonly utilized in industrial processes such as rubber vulcanization and polymer curing to enhance cross-linking and improve material properties. They play a crucial role in manufacturing tires, shoe soles, and conveyor belts by significantly reducing curing time and increasing production efficiency. These accelerators typically work by accelerating the sulfur vulcanization process, enabling faster and more controlled chemical reactions.

Roles and Benefits of Secondary Accelerators

Secondary accelerators complement primary accelerators by providing additional control over the engine's fuel-air mixture, enhancing throttle response and engine efficiency during various driving conditions. Their role includes fine-tuning performance, improving fuel economy, and reducing emissions by adjusting airflow when the primary accelerator alone cannot meet specific demands. You benefit from smoother acceleration and optimized engine behavior, especially during transitions such as idling, startup, and low-speed driving.

Selection Criteria: Choosing the Right Accelerator

Selecting the right accelerator for your startup hinges on understanding the distinct focus of primary and secondary accelerators. Primary accelerators prioritize early-stage ventures with high growth potential, offering intensive mentorship, seed funding, and networking opportunities tailored to your initial business development. Secondary accelerators cater to startups needing growth scaling, emphasizing market expansion, advanced funding rounds, and strategic partnerships to accelerate your business beyond the initial phase.

Comparative Performance in Rubber Compounding

Primary accelerators, such as sulfenamides and thiazoles, offer faster vulcanization and better scorch safety in rubber compounding compared to secondary accelerators like thiurams and dithiocarbamates. Secondary accelerators primarily enhance the cure rate and crosslink density when used in combination with primary accelerators, improving overall mechanical properties and reducing curing time. Your choice between primary and secondary accelerators significantly impacts the balance between processing safety and final rubber performance.

Common Types and Examples of Each Accelerator

Primary accelerators include types such as RISC (Reduced Instruction Set Computer) and CISC (Complex Instruction Set Computer), which directly execute instructions within a CPU to boost performance. Secondary accelerators encompass devices like GPU (Graphics Processing Unit) and FPGA (Field-Programmable Gate Array), specialized for parallel processing tasks and customizable hardware acceleration, respectively. Examples of primary accelerators are Intel Core processors and ARM Cortex chips, while secondary accelerators include NVIDIA GeForce GPUs and Xilinx programmable logic devices.

Future Trends in Accelerator Development

Primary accelerators, designed to increase the speed of the vehicle's engine, are evolving with advancements in electronic throttle control and smart sensors that enable more precise fuel and air mixture regulation. Secondary accelerators, which assist in fine-tuning engine performance during specific conditions, are incorporating adaptive algorithms and IoT connectivity to optimize driving efficiency and reduce emissions. Future trends emphasize integrating AI-driven control systems in both types to enhance responsiveness and provide predictive maintenance alerts tailored to Your vehicle's performance needs.

Primary Accelerator vs Secondary Accelerator Infographic

libmatt.com

libmatt.com