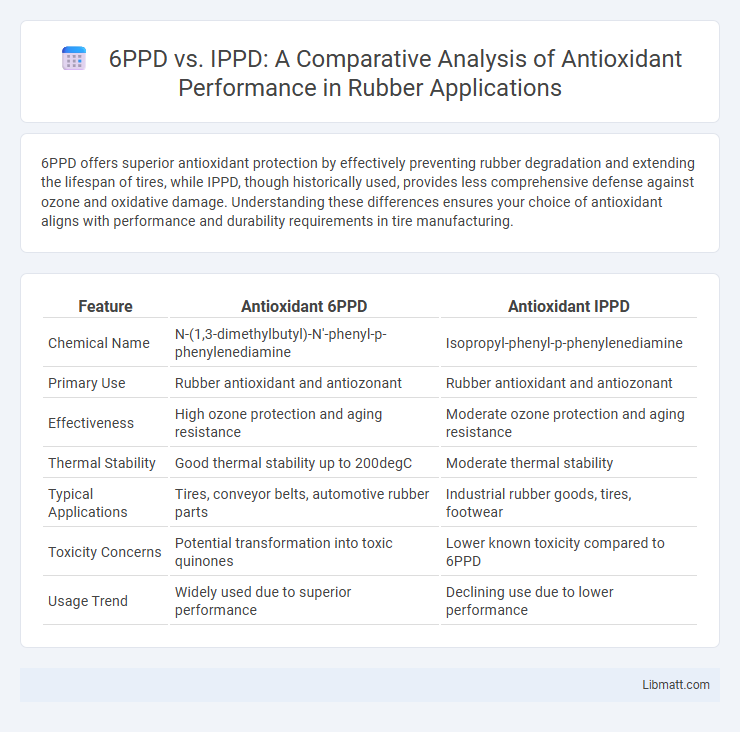

6PPD offers superior antioxidant protection by effectively preventing rubber degradation and extending the lifespan of tires, while IPPD, though historically used, provides less comprehensive defense against ozone and oxidative damage. Understanding these differences ensures your choice of antioxidant aligns with performance and durability requirements in tire manufacturing.

Table of Comparison

| Feature | Antioxidant 6PPD | Antioxidant IPPD |

|---|---|---|

| Chemical Name | N-(1,3-dimethylbutyl)-N'-phenyl-p-phenylenediamine | Isopropyl-phenyl-p-phenylenediamine |

| Primary Use | Rubber antioxidant and antiozonant | Rubber antioxidant and antiozonant |

| Effectiveness | High ozone protection and aging resistance | Moderate ozone protection and aging resistance |

| Thermal Stability | Good thermal stability up to 200degC | Moderate thermal stability |

| Typical Applications | Tires, conveyor belts, automotive rubber parts | Industrial rubber goods, tires, footwear |

| Toxicity Concerns | Potential transformation into toxic quinones | Lower known toxicity compared to 6PPD |

| Usage Trend | Widely used due to superior performance | Declining use due to lower performance |

Introduction to Antioxidants in Rubber Industry

Antioxidants such as 6PPD and IPPD play crucial roles in the rubber industry by preventing oxidative degradation, which extends the lifespan and maintains the performance of rubber products. 6PPD is widely recognized for its superior resistance to ozone and heat aging, making it essential in tire manufacturing and industrial rubber applications. IPPD, while also effective in protecting against oxidative damage, is often used in applications where cost efficiency is prioritized without compromising basic durability.

Overview of 6PPD and IPPD

6PPD (N-(1,3-dimethylbutyl)-N'-phenyl-p-phenylenediamine) and IPPD (N-isopropyl-N'-phenyl-p-phenylenediamine) are widely used antioxidants in rubber and tire manufacturing to prevent oxidative degradation and extend product lifespan. 6PPD is favored for its superior resistance against ozone and heat, making it highly effective in protecting vehicle tires under harsh environmental conditions. Your choice between 6PPD and IPPD depends on the specific durability requirements and regulatory standards for antioxidant performance in rubber applications.

Chemical Structures and Properties

6PPD (N-(1,3-dimethylbutyl)-N'-phenyl-p-phenylenediamine) and IPPD (N-isopropyl-N'-phenyl-p-phenylenediamine) are both p-phenylenediamine antioxidants used in rubber stabilization but differ significantly in their chemical structures and properties. 6PPD features a bulky 1,3-dimethylbutyl side chain that enhances its steric hindrance and oxidation resistance, resulting in superior antiozonant performance compared to the smaller isopropyl group in IPPD. Your choice between 6PPD and IPPD impacts the antioxidant's effectiveness in extending tire and rubber product lifespans by influencing oxidation stability and compatibility with other additives.

Mechanisms of Antioxidant Action

Antioxidants 6PPD and IPPD protect rubber compounds by different mechanisms; 6PPD primarily acts as a radical scavenger, interrupting the oxidative chain reactions that cause polymer degradation, while IPPD functions by preferentially reacting with oxygen-derived radicals, thereby preventing the initiation of polymer oxidation. The enhanced stability and extended durability of rubber products are largely due to 6PPD's ability to form stable quinone derivatives, which effectively neutralize harmful radicals. Understanding these distinct antioxidant actions helps optimize your formulation for increased resistance to aging and environmental damage.

Performance Comparison: 6PPD vs IPPD

6PPD outperforms IPPD in antioxidant performance by providing superior protection against ozone and heat degradation, extending the lifespan of rubber products significantly. Its enhanced stability reduces the rate of polymer oxidation, ensuring better durability in tires and elastomers compared to IPPD. Your choice of 6PPD results in improved overall material longevity and resistance to environmental stress factors.

Applications in Rubber Manufacturing

6PPD and IPPD are crucial antioxidants in rubber manufacturing, preventing degradation caused by heat, oxygen, and ozone. 6PPD is widely favored for its superior antiozonant properties, especially in tire production, enhancing durability and lifespan. Your rubber products benefit from 6PPD's ability to maintain elasticity and prevent cracking, while IPPD is more commonly applied in general-purpose rubber goods with moderate ozone exposure.

Environmental and Health Impacts

6PPD and IPPD are widely used antioxidants in tire rubber, but 6PPD is known for its transformation into 6PPD-quinone, a compound highly toxic to aquatic life, especially coho salmon, causing significant environmental concerns. IPPD, while less studied, also poses potential health risks such as skin sensitization and allergic reactions in humans due to its chemical properties. Understanding these impacts is crucial for minimizing Your exposure and promoting safer alternatives in tire production and disposal.

Regulatory Landscape and Restrictions

Antioxidants 6PPD and IPPD face increasing regulatory scrutiny due to concerns over environmental toxicity and human health risks. 6PPD has been restricted or banned in regions such as the European Union, driven by studies linking its byproducts to aquatic toxicity. IPPD is also under regulatory evaluation globally, with limitations imposed on its concentration in rubber products to mitigate potential allergenic effects and ecological impact.

Market Trends and Availability

The market for antioxidants 6PPD and IPPD shows a growing preference for 6PPD due to its enhanced performance in tire rubber applications, driving increased production and availability globally. Supply chain improvements and rising demand in automotive and industrial sectors have made 6PPD more accessible than IPPD, which faces limited availability due to regulatory restrictions and lower adoption rates. Market trends indicate shifts towards 6PPD as manufacturers prioritize durability, oxidative stability, and environmental compliance in rubber processing.

Future Perspectives and Alternatives

6PPD, a widely used antioxidant in rubber manufacturing, faces increasing regulatory scrutiny due to its environmental toxicity, prompting research into safer alternatives such as IPPD and emerging bio-based antioxidants. Advances in material science emphasize the development of sustainable antioxidants with comparable durability and lower ecological impact, including novel synthetic analogs and natural extracts capable of inhibiting rubber degradation efficiently. Future perspectives prioritize enhancing antioxidant performance through nanotechnology integration and molecular engineering to extend tire lifespan while minimizing environmental hazards.

Antioxidant 6PPD vs IPPD Infographic

libmatt.com

libmatt.com