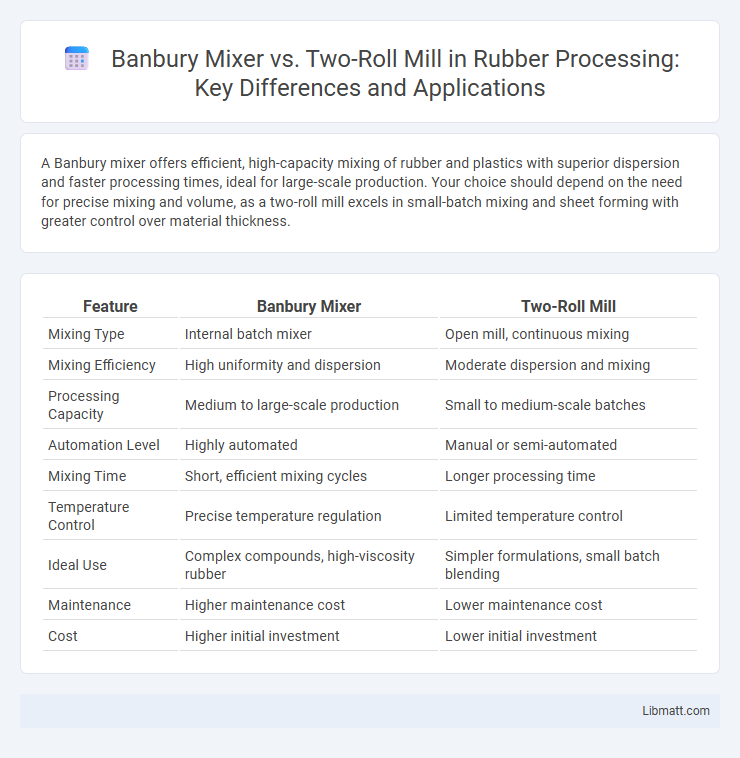

A Banbury mixer offers efficient, high-capacity mixing of rubber and plastics with superior dispersion and faster processing times, ideal for large-scale production. Your choice should depend on the need for precise mixing and volume, as a two-roll mill excels in small-batch mixing and sheet forming with greater control over material thickness.

Table of Comparison

| Feature | Banbury Mixer | Two-Roll Mill |

|---|---|---|

| Mixing Type | Internal batch mixer | Open mill, continuous mixing |

| Mixing Efficiency | High uniformity and dispersion | Moderate dispersion and mixing |

| Processing Capacity | Medium to large-scale production | Small to medium-scale batches |

| Automation Level | Highly automated | Manual or semi-automated |

| Mixing Time | Short, efficient mixing cycles | Longer processing time |

| Temperature Control | Precise temperature regulation | Limited temperature control |

| Ideal Use | Complex compounds, high-viscosity rubber | Simpler formulations, small batch blending |

| Maintenance | Higher maintenance cost | Lower maintenance cost |

| Cost | Higher initial investment | Lower initial investment |

Introduction to Rubber Mixing Technologies

Banbury mixers and two-roll mills are essential machines in rubber processing, each offering distinct advantages for mixing raw materials into uniform compounds. The Banbury mixer excels in high-capacity, intensive mixing with precise temperature control, making it ideal for large-scale rubber production. Your choice between these technologies depends on factors like production volume, mixing efficiency, and the type of rubber compound required.

Overview of Banbury Mixer

The Banbury Mixer is an industrial machine designed for high-intensity mixing of rubber and plastics, ensuring uniform dispersion of fillers and additives through its powerful rotors inside a heated mixing chamber. It offers precise temperature control and efficient energy transfer, making it ideal for producing homogeneous compounds with consistent properties. Compared to the Two-Roll Mill, the Banbury Mixer provides faster mixing cycles and better control over material consistency, particularly in large-scale manufacturing.

Overview of Two-Roll Mill

The Two-Roll Mill is a mechanical device used in the rubber and plastics industries for mixing and sheeting materials. It consists of two horizontally positioned rolls rotating in opposite directions at different speeds to achieve thorough kneading and blending of compounds. This equipment allows precise control over temperature and pressure, making it ideal for processing natural and synthetic rubbers.

Key Differences in Mixing Mechanisms

Banbury Mixers utilize a powerful internal rotor system to create intense shear and compressive forces, ensuring rapid and homogeneous blending of materials, while Two-Roll Mills employ two counter-rotating rolls that crush, stretch, and fold the compound, offering precise control over the mixing and sheeting process. The Banbury Mixer is ideal for high-viscosity rubber and plastic compounds requiring thorough dispersion, whereas the Two-Roll Mill is preferred for lower-viscosity materials and allows manual adjustments during mixing. These fundamental differences in mixing mechanisms directly impact processing speed, heat generation, and consistency of the final product.

Processing Capacities and Efficiency

Banbury Mixers deliver high-speed, intensive mixing ideal for large-scale rubber and polymer processing, achieving superior dispersion with processing capacities ranging from 20 to 400 liters. Two-Roll Mills offer precise, low-volume batch mixing suited for small to medium-scale applications, typically handling capacities up to 50 kilograms with excellent control over compound thickness. Banbury Mixers outperform Two-Roll Mills in processing efficiency by reducing mixing times and minimizing operator intervention, making them preferable for high-throughput manufacturing environments.

Quality and Consistency of Output

Banbury mixers deliver superior quality and consistency of output by ensuring thorough and uniform mixing of rubber and plastic compounds through intense shear and heat control, making them ideal for high-performance materials. Two-roll mills may produce variable results depending on operator skill, temperature control, and mixing time, which can lead to less uniformity and potential inconsistencies in compound properties. Your choice between the two should consider Banbury mixers for precise, repeatable batch quality and two-roll mills for more manual, flexible processing needs.

Applications and Suitable Materials

Banbury mixers excel in processing viscous materials like rubber and plastics, making them ideal for large-scale mixing of composites, adhesives, and elastomers. Two-roll mills are suitable for smaller batch sizes and precise mixing or milling of softer materials such as rubber, plastic sheets, and compounds requiring thorough sheeting or blending. Your choice depends on the scale and consistency needed for materials ranging from heavy-duty rubber compounds to delicate plastic formulations.

Operational Safety and Maintenance

Banbury Mixers feature enclosed designs with advanced safety interlocks, minimizing operator exposure to moving parts and reducing accident risks during operation. Two-Roll Mills require careful handling due to open rolls, increasing potential hazards, though regular maintenance like lubrication and cleaning ensures their safe function. Choosing the appropriate equipment impacts your operational safety protocols and maintenance schedules, influencing overall plant efficiency.

Cost Considerations and Investment

Banbury mixers require a higher initial investment due to advanced technology and robust construction designed for large-scale, continuous mixing applications, but they offer lower operational costs through enhanced efficiency and reduced labor. Two-roll mills have a lower upfront cost, making them suitable for small to medium-sized production, yet their manual operation and slower processing can lead to higher long-term expenses. Evaluating total cost of ownership, including maintenance and energy consumption, is crucial when choosing between Banbury mixers and two-roll mills for rubber and plastic compounding.

Choosing the Right Mixing Equipment

Choosing the right mixing equipment depends on factors such as material viscosity, batch size, and mixing precision. Banbury mixers excel in high-viscosity compounds and large-scale production due to their enclosed, high-torque mixing chambers, ensuring efficient heat control and uniform dispersion. Two-roll mills are preferred for small batches and materials requiring shearing and surface mixing, providing greater control over thickness and texture in rubber and plastic processing.

Banbury Mixer vs Two-Roll Mill Infographic

libmatt.com

libmatt.com