Zinc-free accelerators eliminate the risk of zinc-related environmental toxicity while maintaining efficient vulcanization processes in rubber manufacturing. Your choice between zinc-free and zinc oxide-based accelerators should consider factors like sustainability goals, regulatory compliance, and the specific performance requirements of the rubber compound.

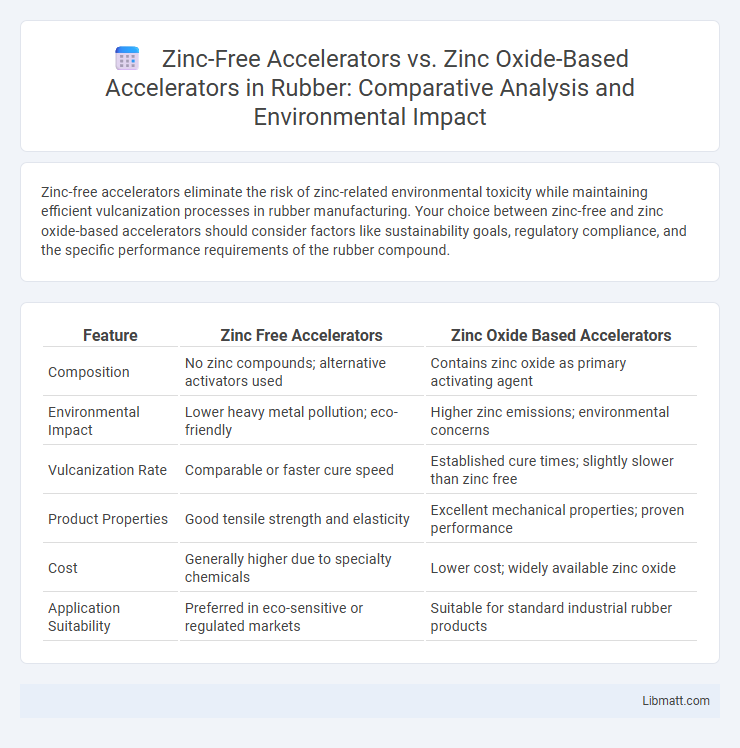

Table of Comparison

| Feature | Zinc Free Accelerators | Zinc Oxide Based Accelerators |

|---|---|---|

| Composition | No zinc compounds; alternative activators used | Contains zinc oxide as primary activating agent |

| Environmental Impact | Lower heavy metal pollution; eco-friendly | Higher zinc emissions; environmental concerns |

| Vulcanization Rate | Comparable or faster cure speed | Established cure times; slightly slower than zinc free |

| Product Properties | Good tensile strength and elasticity | Excellent mechanical properties; proven performance |

| Cost | Generally higher due to specialty chemicals | Lower cost; widely available zinc oxide |

| Application Suitability | Preferred in eco-sensitive or regulated markets | Suitable for standard industrial rubber products |

Introduction to Rubber Accelerators

Rubber accelerators enhance vulcanization, improving rubber's strength, elasticity, and durability. Zinc-free accelerators reduce environmental impact and health hazards compared to traditional zinc oxide-based accelerators, which are widely used for their effectiveness in speeding up cross-linking reactions. Choosing the right accelerator affects your rubber formulation's performance and compliance with regulatory standards.

What Are Zinc Free Accelerators?

Zinc free accelerators are chemical compounds used in rubber vulcanization that do not contain zinc oxide, aiming to provide efficient curing without the environmental and health concerns linked to zinc. These accelerators promote faster cross-linking and improved processing safety while maintaining or enhancing the mechanical properties of the final rubber product. You can choose zinc free accelerators to reduce zinc pollution and regulatory risks associated with traditional zinc oxide based accelerators.

Overview of Zinc Oxide Based Accelerators

Zinc oxide based accelerators are widely used in the rubber vulcanization process due to their efficiency in speeding up curing and enhancing the mechanical properties of rubber products. They act as activators by facilitating the cross-linking between sulfur and rubber molecules, resulting in improved elasticity, strength, and durability. Your choice of zinc oxide based accelerators can significantly impact the overall performance and longevity of rubber materials in industrial applications.

Environmental Impact: Zinc Free vs Zinc Oxide

Zinc free accelerators significantly reduce environmental toxicity by eliminating zinc discharge, which can contaminate soil and waterways, harming aquatic life and ecosystems. Zinc oxide-based accelerators contribute to heavy metal accumulation and pose challenges in wastewater treatment due to persistent zinc residues. Choosing zinc free accelerators supports cleaner production processes and aligns with sustainable manufacturing goals, minimizing your environmental footprint.

Performance and Efficiency Comparison

Zinc-free accelerators demonstrate superior environmental compliance and reduced toxicity compared to traditional zinc oxide-based accelerators, while maintaining comparable curing speeds and adhesion properties in rubber vulcanization. The efficiency of zinc-free alternatives is enhanced by their ability to minimize zinc leaching into the environment, contributing to sustainable manufacturing practices without compromising product durability. Performance metrics indicate that zinc-free accelerators offer stable crosslink density and mechanical strength, matching or exceeding the effectiveness of zinc oxide-based systems in various industrial applications.

Health and Safety Considerations

Zinc free accelerators significantly reduce the risk of skin irritation and respiratory issues compared to zinc oxide based accelerators, which are known to release airborne zinc oxide particles that may cause occupational hazards. Your workplace safety improves with zinc free options due to lower toxicity and diminished environmental impact. Proper handling protocols remain essential, but zinc free accelerators offer a safer alternative for long-term health protection in rubber vulcanization processes.

Cost Implications and Economic Factors

Zinc free accelerators generally offer cost savings compared to zinc oxide-based accelerators due to lower raw material prices and reduced environmental compliance costs. The economic benefits include decreased production expenses, which can improve your overall profitability in rubber manufacturing. However, zinc oxide accelerators often provide enhanced performance, so balancing cost with product quality is essential for optimal economic outcomes.

Regulatory Trends and Industry Standards

Zinc Free Accelerators are gaining traction due to stricter regulatory trends aimed at reducing zinc pollution in rubber manufacturing, especially in the European Union where REACH regulations impose limits on zinc content. Industry standards are increasingly favoring zinc-free alternatives to comply with environmental directives and ensure safer disposal, promoting sustainable manufacturing practices. Zinc Oxide Based Accelerators, while effective, face growing scrutiny under global environmental regulations, driving innovation toward zinc-free formulations in the rubber industry.

Application Areas and Suitability

Zinc-free accelerators are primarily used in industries requiring low toxicity and enhanced environmental compliance, such as medical gloves and food-grade rubber products. Zinc oxide-based accelerators are favored in heavy-duty applications like automotive tires and industrial conveyor belts due to their superior vulcanization speed and mechanical strength enhancement. Selecting the suitable accelerator depends on the specific product requirements, environmental regulations, and desired rubber properties.

Future Outlook of Rubber Accelerator Technologies

Zinc free accelerators offer significant environmental benefits by reducing toxic zinc oxide content while maintaining efficient vulcanization processes, aligning with stricter global regulations. Emerging rubber accelerator technologies emphasize improved sustainability and performance, incorporating bio-based and specialty additives to enhance rubber durability and processing speed. Your choice of zinc free or zinc oxide based accelerators will shape the future of rubber production, balancing regulatory compliance and product quality advancements.

Zinc Free Accelerators vs Zinc Oxide Based Accelerators Infographic

libmatt.com

libmatt.com