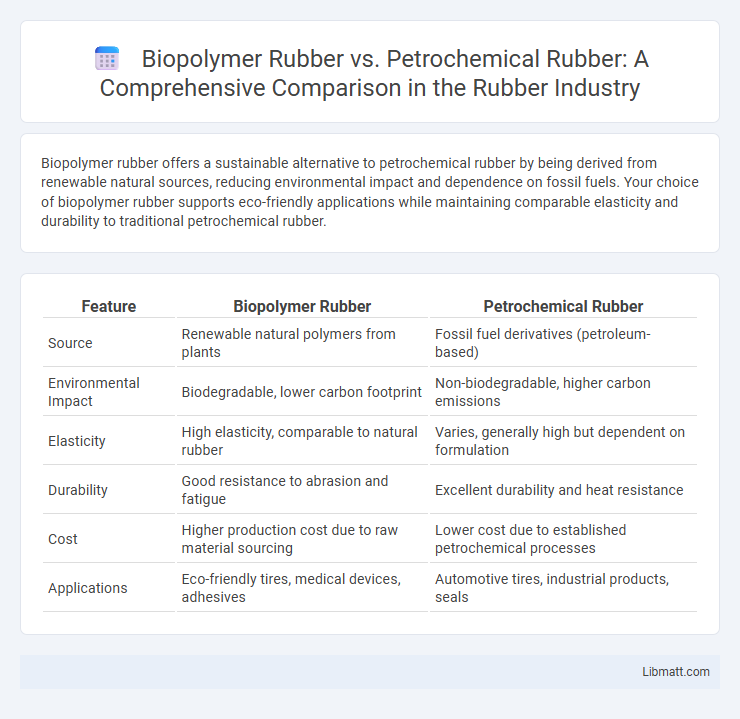

Biopolymer rubber offers a sustainable alternative to petrochemical rubber by being derived from renewable natural sources, reducing environmental impact and dependence on fossil fuels. Your choice of biopolymer rubber supports eco-friendly applications while maintaining comparable elasticity and durability to traditional petrochemical rubber.

Table of Comparison

| Feature | Biopolymer Rubber | Petrochemical Rubber |

|---|---|---|

| Source | Renewable natural polymers from plants | Fossil fuel derivatives (petroleum-based) |

| Environmental Impact | Biodegradable, lower carbon footprint | Non-biodegradable, higher carbon emissions |

| Elasticity | High elasticity, comparable to natural rubber | Varies, generally high but dependent on formulation |

| Durability | Good resistance to abrasion and fatigue | Excellent durability and heat resistance |

| Cost | Higher production cost due to raw material sourcing | Lower cost due to established petrochemical processes |

| Applications | Eco-friendly tires, medical devices, adhesives | Automotive tires, industrial products, seals |

Introduction to Biopolymer and Petrochemical Rubbers

Biopolymer rubber, derived from natural, renewable sources like plants and microorganisms, offers enhanced biodegradability and reduced environmental impact compared to petrochemical rubber, which is produced from non-renewable fossil fuels such as crude oil and natural gas. Petrochemical rubbers, including synthetic variants like styrene-butadiene rubber (SBR) and nitrile rubber (NBR), provide superior durability, chemical resistance, and performance consistency for industrial applications. The growing demand for sustainable materials drives research and development in biopolymer rubber to match or exceed the mechanical properties and longevity of traditional petrochemical rubbers.

Chemical Structure and Composition Differences

Biopolymer rubber is derived from renewable natural sources such as plants, primarily composed of cis-1,4-polyisoprene, which gives it a natural, flexible, and elastic molecular structure. Petrochemical rubber, on the other hand, is synthesized from fossil fuel-based monomers like styrene and butadiene, resulting in a more complex mixture of synthetic polymers with varied physical and chemical properties. Your choice between biopolymer and petrochemical rubber depends on the desired balance between sustainability and performance characteristics linked to their distinct chemical compositions.

Sourcing and Raw Material Origins

Biopolymer rubber is derived from renewable natural sources such as Hevea brasiliensis (rubber tree) latex and other plant-based materials, ensuring sustainability and reduced environmental impact. Petrochemical rubber, conversely, is synthesized from fossil fuels like crude oil and natural gas, relying heavily on non-renewable resources with a significant carbon footprint. The sourcing of biopolymer rubber emphasizes biodegradability and ecological balance, while petrochemical rubber prioritizes consistent quality and large-scale production capacity.

Environmental Impact and Sustainability

Biopolymer rubber significantly reduces environmental impact by being biodegradable and sourced from renewable materials, unlike petrochemical rubber, which relies on fossil fuels and generates higher carbon emissions during production. The sustainable cultivation of rubber trees and advances in biopolymer technology promote carbon sequestration and reduce reliance on non-renewable resources, enhancing the circular economy. In contrast, petrochemical rubber contributes to pollution through extraction processes and slow decomposition, posing long-term ecological risks.

Performance and Mechanical Properties

Biopolymer rubber often exhibits superior elasticity, tensile strength, and abrasion resistance compared to petrochemical rubber due to its natural polymer structure and eco-friendly cross-linking processes. Petrochemical rubber, while offering consistent performance and well-understood mechanical properties such as hardness and resilience, may experience degradation under UV exposure and higher temperatures. Advances in biopolymer formulations have enhanced durability and flexibility, making them competitive alternatives for automotive tires, seals, and vibration dampening applications.

Cost Comparison and Economic Viability

Biopolymer rubber generally incurs higher production costs than petrochemical rubber due to limited raw material availability and less established manufacturing processes. Petrochemical rubber benefits from economies of scale and established supply chains, making it more economically viable for large-scale applications. However, ongoing advancements in biopolymer technology and increasing environmental regulations are progressively improving the cost competitiveness and market feasibility of biopolymer rubber.

Industrial Applications and Market Trends

Biopolymer rubber is increasingly adopted in automotive and medical industries due to its biodegradability and sustainable sourcing, offering a competitive edge over petrochemical rubber, which dominates heavy machinery and construction sectors for its durability and cost-efficiency. Market trends indicate growing investment in biopolymer rubber technologies driven by environmental regulations and consumer demand for eco-friendly products, while petrochemical rubber maintains stability through established supply chains and cost advantages. Industrial applications reflect a shift toward biopolymer composites in tire manufacturing and wearable devices, contrasting with petrochemical rubber's prevalence in conveyor belts and industrial seals.

Challenges in Production and Processing

Biopolymer rubber faces challenges in production due to limited raw material availability and variability in feedstock quality, impacting consistent polymer properties. Processing difficulties include lower thermal stability and different curing behaviors compared to petrochemical rubber, requiring specialized equipment and formulations. Your transition to biopolymer rubber necessitates adapting manufacturing processes to address these material-specific constraints and ensure product performance.

Regulatory Standards and Certifications

Biopolymer rubber complies with emerging regulatory standards such as REACH and FDA guidelines for sustainability and non-toxicity, positioning it favorably in eco-conscious markets. Petrochemical rubber must meet established industrial certifications like ASTM and ISO, ensuring consistent performance but raising environmental compliance challenges. Increasingly stringent global regulations are driving demand for biopolymer rubber certifications, including USDA BioPreferred and EN 13432 for biodegradability, emphasizing its regulatory advantage.

Future Prospects and Innovation in Rubber Technology

Biopolymer rubber offers significant environmental advantages over petrochemical rubber, driving innovation toward sustainable materials with lower carbon footprints. Research in biopolymer rubber focuses on enhancing elasticity, durability, and biodegradability through advanced bioengineering and green chemistry techniques. Future prospects include integrating biopolymer rubber with smart technologies, enabling self-healing properties and improved performance in automotive and industrial applications, positioning it as a key player in the shift toward eco-friendly rubber solutions.

Biopolymer rubber vs Petrochemical rubber Infographic

libmatt.com

libmatt.com