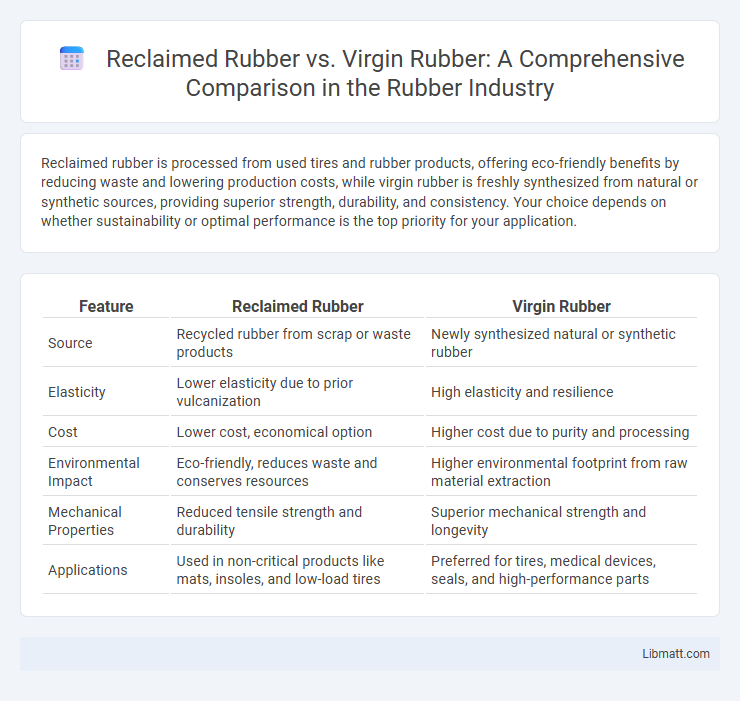

Reclaimed rubber is processed from used tires and rubber products, offering eco-friendly benefits by reducing waste and lowering production costs, while virgin rubber is freshly synthesized from natural or synthetic sources, providing superior strength, durability, and consistency. Your choice depends on whether sustainability or optimal performance is the top priority for your application.

Table of Comparison

| Feature | Reclaimed Rubber | Virgin Rubber |

|---|---|---|

| Source | Recycled rubber from scrap or waste products | Newly synthesized natural or synthetic rubber |

| Elasticity | Lower elasticity due to prior vulcanization | High elasticity and resilience |

| Cost | Lower cost, economical option | Higher cost due to purity and processing |

| Environmental Impact | Eco-friendly, reduces waste and conserves resources | Higher environmental footprint from raw material extraction |

| Mechanical Properties | Reduced tensile strength and durability | Superior mechanical strength and longevity |

| Applications | Used in non-critical products like mats, insoles, and low-load tires | Preferred for tires, medical devices, seals, and high-performance parts |

Introduction to Reclaimed and Virgin Rubber

Reclaimed rubber is produced by processing scrap rubber materials through mechanical and chemical treatments, making it a cost-effective and sustainable alternative in manufacturing. Virgin rubber, derived directly from fresh natural latex or synthetic rubber compounds, offers superior elasticity, tensile strength, and durability crucial for high-performance applications. Understanding the distinct physical and chemical properties of reclaimed versus virgin rubber helps industries optimize product quality and environmental impact.

Defining Reclaimed Rubber

Reclaimed rubber is produced by processing used rubber materials through devulcanization, restoring them to a reusable state without sacrificing flexibility and strength. Unlike virgin rubber, which is derived directly from fresh natural latex or synthetic polymers, reclaimed rubber offers an eco-friendly and cost-effective alternative by recycling waste rubber products. Understanding reclaimed rubber helps you choose sustainable materials that reduce environmental impact while meeting performance requirements.

Understanding Virgin Rubber

Virgin rubber is a natural or synthetic elastomer harvested directly from rubber trees or produced through polymerization processes, ensuring high purity and consistent molecular structure. It exhibits superior physical properties such as elasticity, tensile strength, and thermal stability crucial for demanding applications like tires, seals, and medical devices. The controlled manufacturing environment reduces impurities and contamination, providing predictable performance and long service life compared to reclaimed rubber.

Key Differences in Production Processes

Reclaimed rubber is produced by recycling used rubber products through processes like devulcanization, which breaks down the cross-linked structure to restore elasticity, while virgin rubber is obtained directly from fresh latex or synthetic materials without prior use. The production of reclaimed rubber involves energy-intensive mechanical and chemical treatments to remove contaminants and restore properties, contrasting with the straightforward extraction and purification of virgin rubber. Your choice between reclaimed and virgin rubber impacts product quality, cost, and environmental footprint due to these fundamental differences in production processes.

Environmental Impact Comparison

Reclaimed rubber significantly reduces environmental impact by recycling scrap rubber, lowering landfill waste, and decreasing the demand for new raw materials compared to virgin rubber. Virgin rubber production involves intensive resource consumption, including deforestation and high energy use, contributing to greater carbon emissions. Using reclaimed rubber supports circular economy practices and reduces pollution associated with rubber processing and disposal.

Performance and Durability Analysis

Reclaimed rubber exhibits lower tensile strength and elasticity compared to virgin rubber, resulting in reduced performance in high-stress applications. Virgin rubber maintains superior durability due to its intact molecular structure, offering enhanced resistance to wear, heat, and aging. The performance disparity makes virgin rubber preferable for critical uses requiring long-term reliability and consistent material properties.

Cost Efficiency and Economic Benefits

Reclaimed rubber offers significant cost efficiency by utilizing recycled materials, resulting in lower raw material expenses compared to virgin rubber. The economic benefits include reduced production costs and decreased environmental impact, which align with sustainable business practices. Your choice of reclaimed rubber can lead to improved profitability while supporting eco-friendly initiatives.

Common Applications and Industry Usage

Reclaimed rubber is widely utilized in industries such as automotive, footwear, and construction for products like tire retreading, shoe soles, and mats due to its cost-effectiveness and sustainability benefits. Virgin rubber is preferred in high-performance applications including aerospace, medical devices, and specialty seals where superior elasticity, strength, and purity are critical. Both materials serve essential roles, with reclaimed rubber supporting eco-friendly manufacturing and virgin rubber ensuring uncompromised durability and quality.

Sustainability and Circular Economy Perspectives

Reclaimed rubber plays a crucial role in advancing sustainability by reducing landfill waste and conserving natural resources, as it is produced through recycling discarded rubber products. Virgin rubber, derived from fresh natural latex or synthetic sources, requires significant energy and raw material input, contributing to higher environmental footprints. Incorporating reclaimed rubber into manufacturing supports a circular economy by promoting material reuse and minimizing the demand for raw rubber extraction, thus aligning with eco-friendly production practices.

Future Trends in Rubber Material Selection

Future trends in rubber material selection lean towards increasing incorporation of reclaimed rubber due to its cost-effectiveness and environmental benefits, supporting circular economy initiatives. Advances in recycling technologies are enhancing the performance qualities of reclaimed rubber, narrowing the gap with virgin rubber in applications requiring durability and elasticity. Continued regulatory pressure and consumer demand for sustainable products are driving manufacturers to prioritize blends of reclaimed and virgin rubber to optimize material properties while minimizing ecological impact.

Reclaimed rubber vs Virgin rubber Infographic

libmatt.com

libmatt.com