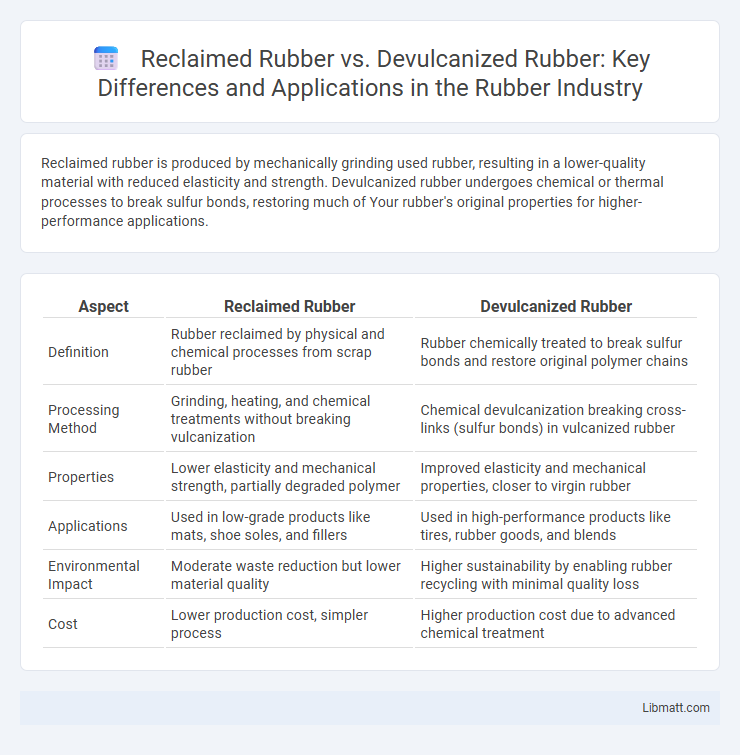

Reclaimed rubber is produced by mechanically grinding used rubber, resulting in a lower-quality material with reduced elasticity and strength. Devulcanized rubber undergoes chemical or thermal processes to break sulfur bonds, restoring much of Your rubber's original properties for higher-performance applications.

Table of Comparison

| Aspect | Reclaimed Rubber | Devulcanized Rubber |

|---|---|---|

| Definition | Rubber reclaimed by physical and chemical processes from scrap rubber | Rubber chemically treated to break sulfur bonds and restore original polymer chains |

| Processing Method | Grinding, heating, and chemical treatments without breaking vulcanization | Chemical devulcanization breaking cross-links (sulfur bonds) in vulcanized rubber |

| Properties | Lower elasticity and mechanical strength, partially degraded polymer | Improved elasticity and mechanical properties, closer to virgin rubber |

| Applications | Used in low-grade products like mats, shoe soles, and fillers | Used in high-performance products like tires, rubber goods, and blends |

| Environmental Impact | Moderate waste reduction but lower material quality | Higher sustainability by enabling rubber recycling with minimal quality loss |

| Cost | Lower production cost, simpler process | Higher production cost due to advanced chemical treatment |

Introduction to Reclaimed and Devulcanized Rubber

Reclaimed rubber is produced by mechanically grinding scrap rubber to restore flexibility and improve processing, making it widely used in rubber manufacturing for cost efficiency and sustainability. Devulcanized rubber involves breaking sulfur cross-links in vulcanized rubber through chemical or thermal processes, enabling the material to regain its original properties for reuse in high-performance applications. Both methods contribute significantly to rubber recycling by reducing waste and promoting circular economy practices within the industry.

What is Reclaimed Rubber?

Reclaimed rubber is produced by mechanically grinding scrap rubber and treating it with heat and chemicals to restore its pliability and usability for new products. This process breaks down the rubber's cross-linked structure without fully reversing vulcanization, resulting in material with reduced mechanical properties compared to virgin rubber. Reclaimed rubber is commonly used in applications such as automotive parts, footwear, and mats where cost-effectiveness and partial material recovery are prioritized.

What is Devulcanized Rubber?

Devulcanized rubber is rubber that has undergone a specialized chemical or mechanical process to break down the sulfur cross-links formed during vulcanization, restoring its original elastic properties. This process allows the rubber to be reprocessed and reused with enhanced flexibility and durability compared to reclaimed rubber, which is mainly ground and lacks full restoration of its molecular structure. Understanding devulcanized rubber helps optimize recycling efforts and improve the quality of rubber materials in your manufacturing applications.

Production Processes Compared

Reclaimed rubber is produced by grinding scrap rubber and applying heat and chemicals to restore flexibility, while devulcanized rubber undergoes a specialized chemical or thermal process to break sulfur bonds without damaging the polymer chains. The devulcanization process allows the rubber to regain its original properties more effectively compared to reclaimed rubber, which typically has reduced mechanical performance. Production of devulcanized rubber requires precise control of temperature and chemicals to ensure selective bond breaking, whereas reclaimed rubber production is more straightforward but less selective.

Material Properties and Performance

Reclaimed rubber retains much of the original vulcanized rubber's elasticity but often exhibits lower tensile strength and abrasion resistance compared to devulcanized rubber, which undergoes chemical processes to break sulphur cross-links, restoring polymer chain mobility. Devulcanized rubber offers improved flexibility, durability, and mechanical properties close to virgin rubber, making it suitable for high-performance applications. Both materials provide cost-effective recycling solutions, yet devulcanized rubber demonstrates superior performance in dynamic environments requiring resilience and elasticity.

Environmental Impact and Sustainability

Reclaimed rubber is produced through mechanical grinding of scrap rubber, resulting in lower energy consumption but limited reuse potential compared to devulcanized rubber, which undergoes chemical or thermal processes to break sulfur bonds, enabling near-original material properties for extensive recycling. Devulcanized rubber supports a circular economy by significantly reducing landfill waste and conserving natural rubber resources, contributing to lower carbon emissions in the manufacturing lifecycle. Your choice between reclaimed and devulcanized rubber affects sustainability outcomes by balancing energy use and material quality in eco-friendly production.

Cost Analysis and Economic Benefits

Reclaimed rubber offers a lower-cost alternative to virgin rubber by utilizing scrap materials through mechanical grinding and heating processes, reducing raw material expenses. Devulcanized rubber, produced via chemical or thermal methods to break sulfur bonds, provides superior elasticity and performance, which can command higher market prices despite increased processing costs. Companies benefit economically by choosing reclaimed rubber for cost-sensitive applications, while devulcanized rubber proves advantageous in high-value products requiring enhanced durability and lifecycle savings.

Applications in Industry

Reclaimed rubber is widely used in non-structural applications such as rubber mats, flooring, and molded goods where cost-effectiveness and moderate performance are prioritized. Devulcanized rubber, possessing properties closer to virgin rubber, finds applications in high-performance tires, automotive parts, and industrial seals requiring enhanced elasticity and durability. Both materials contribute significantly to sustainable manufacturing by reducing waste in rubber-intensive industries.

Challenges and Limitations

Reclaimed rubber faces challenges such as inconsistent quality and limited mechanical properties due to incomplete removal of crosslinks, which affect its usability in high-performance applications. Devulcanized rubber offers improved properties by selectively breaking sulfur bonds, but it involves complex processes that are energy-intensive and costly, limiting large-scale adoption. Your choice depends on balancing economic factors against desired material performance and application requirements.

Future Trends in Rubber Recycling

Reclaimed rubber and devulcanized rubber represent crucial advancements in sustainable rubber recycling, with future trends emphasizing improved chemical processes to enhance material properties and reduce environmental impact. Innovations in devulcanization technologies enable higher-quality rubber suitable for diverse applications, fostering a circular economy in the tire and rubber industry. Your choice to utilize these materials supports the growing demand for eco-friendly alternatives while promoting resource efficiency and waste reduction.

Reclaimed Rubber vs Devulcanized Rubber Infographic

libmatt.com

libmatt.com