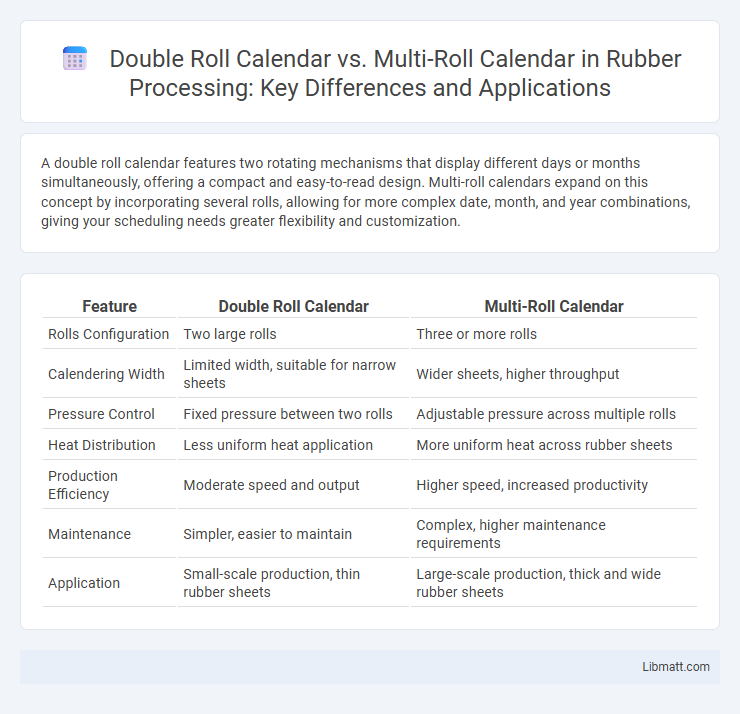

A double roll calendar features two rotating mechanisms that display different days or months simultaneously, offering a compact and easy-to-read design. Multi-roll calendars expand on this concept by incorporating several rolls, allowing for more complex date, month, and year combinations, giving your scheduling needs greater flexibility and customization.

Table of Comparison

| Feature | Double Roll Calendar | Multi-Roll Calendar |

|---|---|---|

| Rolls Configuration | Two large rolls | Three or more rolls |

| Calendering Width | Limited width, suitable for narrow sheets | Wider sheets, higher throughput |

| Pressure Control | Fixed pressure between two rolls | Adjustable pressure across multiple rolls |

| Heat Distribution | Less uniform heat application | More uniform heat across rubber sheets |

| Production Efficiency | Moderate speed and output | Higher speed, increased productivity |

| Maintenance | Simpler, easier to maintain | Complex, higher maintenance requirements |

| Application | Small-scale production, thin rubber sheets | Large-scale production, thick and wide rubber sheets |

Introduction to Calendering in Manufacturing

Calendering in manufacturing involves passing materials through rollers to achieve precise thickness and surface finish, critical for industries like textiles, plastics, and rubber. Double roll calendars consist of two rollers, providing uniform material thickness with moderate pressure, ideal for simpler applications. Multi-roll calendars offer increased control and higher pressure with multiple rollers, enhancing product quality and consistency for more complex or high-volume production, making your choice dependent on specific manufacturing needs.

Overview: Double Roll Calendar

Double Roll Calendar systems feature two parallel rolls that facilitate smoother and more efficient paper dispensing, commonly used in facilities requiring high-volume usage. This design reduces the frequency of roll changes compared to single-roll calendars, enhancing operational efficiency. Your choice between Double Roll and Multi-roll calendars depends on traffic levels and maintenance preferences, with Double Roll often preferred for mid-sized demand environments.

Overview: Multi-Roll Calendar

The Multi-Roll Calendar offers enhanced organizational efficiency by accommodating multiple rolls of labels or receipts simultaneously, making it ideal for high-volume printing environments. It supports seamless transitions between different media types or sizes, reducing downtime and improving productivity. Your workflow benefits from greater flexibility and minimized material wastage compared to the Double Roll Calendar setup.

Key Differences Between Double Roll and Multi-Roll Calendars

Double roll calendars feature two paper rolls designed primarily for healthcare and hospitality sectors, enabling continuous use with fewer replacements. Multi-roll calendars accommodate three or more rolls, offering extended capacity and reduced maintenance suitable for high-traffic commercial environments. Key differences include roll capacity, replacement frequency, and optimal use cases tailored to various business needs.

Material Compatibility and Application Areas

Double roll calendars feature two rollers that ensure a more uniform pressure distribution, making them ideal for processing materials like PVC, polyurethane, and rubber composites that require precise thickness control. Multi-roll calendars incorporate multiple rollers arranged in series, offering enhanced adaptability for a wider range of materials such as thermoplastics, laminates, and advanced composites used in automotive and aerospace applications. Material compatibility with double roll systems centers on consistency and surface finish, while multi-roll calendars excel in complex layering and higher throughput demands across diverse industrial sectors.

Performance and Output Quality Comparison

Double roll calendars typically offer higher output quality due to their ability to maintain consistent tension and alignment, which reduces defects and enhances print sharpness. Multi-roll calendars excel in performance by enabling faster processing speeds and greater production flexibility, accommodating various material types and thicknesses more efficiently. While double roll systems prioritize precision and surface finish, multi-roll setups optimize throughput and adaptability for diverse manufacturing demands.

Operational Efficiency and Maintenance

Double roll calendars enhance operational efficiency by simplifying adjustments with two adjustable rolls, making your production line faster and more precise. Multi-roll calendars support higher throughput and improved surface quality by increasing the number of rolls, but they require more complex maintenance routines to ensure consistent performance. Assess your operational needs and maintenance capacity to determine which calendar system aligns best with your production goals.

Cost Analysis: Double Roll vs Multi-Roll

Double roll calendars generally offer a lower initial cost compared to multi-roll calendars, making them a budget-friendly option for small businesses. Multi-roll calendars, while more expensive, provide greater durability and convenience by allowing access to multiple rolls simultaneously, reducing downtime and replacement frequency. Your choice should weigh the upfront expenses against long-term savings and operational efficiency for optimal cost management.

Choosing the Right Calendar for Your Process

Double roll calendars offer a compact solution with two interchangeable rolls, ideal for processes requiring frequent material changes and minimal downtime. Multi-roll calendars provide versatility with multiple rolls, supporting complex manufacturing workflows and enhanced productivity by handling various materials simultaneously. Selecting the right calendar depends on process requirements, production volume, and material types to optimize efficiency and output quality.

Future Trends in Calendar Technology

Double roll calendars offer streamlined date management with two rotating drums, while multi-roll calendars enhance flexibility by incorporating multiple rotating segments for day, date, month, and year. Future trends in calendar technology emphasize digital integration, AI-driven scheduling, and customizable smart displays that adapt to user preferences and optimize productivity. Advancements in augmented reality and voice-activated commands are poised to revolutionize how users interact with both double roll and multi-roll calendar systems.

Double roll calendar vs Multi-roll calendar Infographic

libmatt.com

libmatt.com