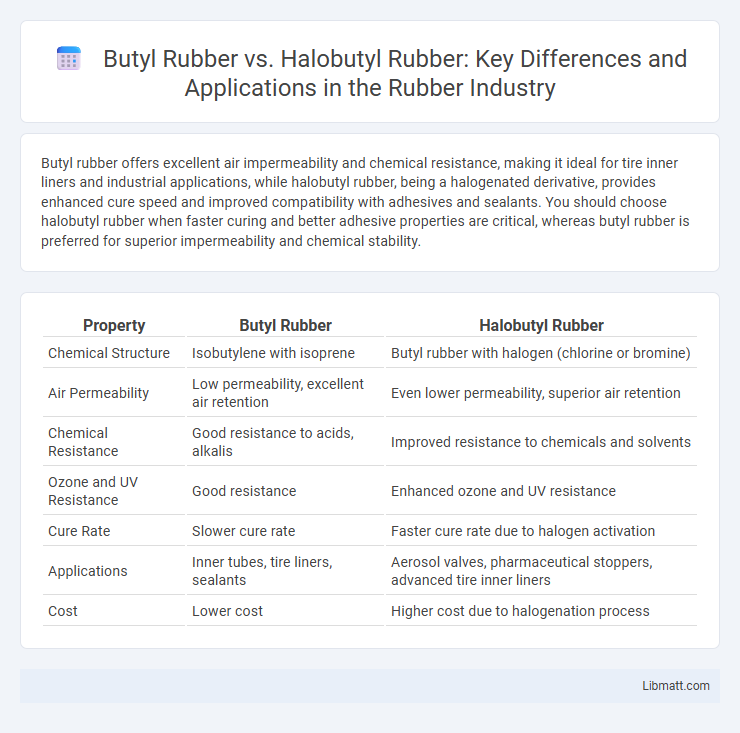

Butyl rubber offers excellent air impermeability and chemical resistance, making it ideal for tire inner liners and industrial applications, while halobutyl rubber, being a halogenated derivative, provides enhanced cure speed and improved compatibility with adhesives and sealants. You should choose halobutyl rubber when faster curing and better adhesive properties are critical, whereas butyl rubber is preferred for superior impermeability and chemical stability.

Table of Comparison

| Property | Butyl Rubber | Halobutyl Rubber |

|---|---|---|

| Chemical Structure | Isobutylene with isoprene | Butyl rubber with halogen (chlorine or bromine) |

| Air Permeability | Low permeability, excellent air retention | Even lower permeability, superior air retention |

| Chemical Resistance | Good resistance to acids, alkalis | Improved resistance to chemicals and solvents |

| Ozone and UV Resistance | Good resistance | Enhanced ozone and UV resistance |

| Cure Rate | Slower cure rate | Faster cure rate due to halogen activation |

| Applications | Inner tubes, tire liners, sealants | Aerosol valves, pharmaceutical stoppers, advanced tire inner liners |

| Cost | Lower cost | Higher cost due to halogenation process |

Introduction to Butyl Rubber and Halobutyl Rubber

Butyl rubber, a synthetic elastomer known for excellent impermeability and chemical resistance, is widely used in tire inner linings and sealing applications. Halobutyl rubber, a modified version of butyl rubber, incorporates halogen atoms to enhance cure rate, heat resistance, and adhesion properties, making it ideal for medical and automotive uses. Understanding the distinct characteristics of these materials helps you select the optimal rubber for your specific industrial or commercial needs.

Chemical Composition Differences

Butyl rubber consists primarily of isobutylene with a small amount of isoprene, providing excellent impermeability and flexibility. Halobutyl rubber is chemically modified by halogenation, typically chlorination or bromination, which enhances its chemical resistance and curing properties compared to standard butyl rubber. Your choice between these materials depends on the required balance of chemical resistance and processing performance.

Manufacturing Processes

Butyl rubber is produced through the copolymerization of isobutylene with a small amount of isoprene, typically using a cationic polymerization process at low temperatures. Halobutyl rubber, derived from butyl rubber, undergoes a post-polymerization halogenation step where chlorine or bromine atoms are introduced to enhance chemical resistance and curing efficiency. The halogenation process improves halobutyl's performance in sealing and tire inner liners by increasing its impermeability and compatibility with sulfur curing agents.

Key Physical Properties

Butyl rubber exhibits excellent impermeability to gases, superior flexibility, and high resistance to heat, ozone, and weathering, making it ideal for applications requiring airtight seals. Halobutyl rubber, a halogenated form of butyl, offers enhanced chemical resistance, improved cure rates, and better adhesion properties compared to standard butyl rubber. Both materials maintain excellent low-temperature flexibility, but halobutyl rubber is favored in tire inner liners and pharmaceutical stoppers for its superior barrier and durability performance.

Air and Gas Permeability

Butyl rubber exhibits moderate air and gas permeability, making it suitable for applications requiring general impermeability, while halobutyl rubber significantly enhances gas barrier properties due to its halogenation process. Halobutyl rubber's lower permeability to gases like oxygen and nitrogen makes it the preferred material for inner liners in tubeless tires and pharmaceutical stoppers. The improved chemical resistance and reduced air transmission rates of halobutyl rubber extend product shelf life and performance in sealing applications.

Resistance to Chemicals and Aging

Butyl rubber exhibits strong resistance to a wide range of chemicals, including acids and bases, but halobutyl rubber offers superior resistance to ozone, weathering, and aging due to its improved molecular structure with halogen atoms. Halobutyl rubber's enhanced impermeability to gases and resistance to oxidation make it the preferred choice for applications requiring long-term durability in harsh environments. Selecting halobutyl rubber for your products ensures better chemical stability and extended lifespan compared to traditional butyl rubber.

Typical Applications in Industry

Butyl rubber is widely used in tire inner liners, adhesives, and sealants thanks to its excellent impermeability and flexibility, making it ideal for automotive and pharmaceutical applications. Halobutyl rubber, enhanced by halogenation, offers superior resistance to heat, chemicals, and weathering, which suits it for high-performance tire inner liners, pharmaceutical stoppers, and industrial gaskets. Your choice between these rubbers depends on application-specific requirements such as chemical resistance, durability, and cost-effectiveness in demanding environments.

Cost Comparison and Availability

Butyl rubber generally offers lower raw material costs and wider availability compared to halobutyl rubber, making it a more budget-friendly choice for many applications. Halobutyl rubber, although more expensive due to its enhanced impermeability and chemical resistance, is available in smaller quantities and specialized markets. Your decision depends on balancing cost constraints with the performance benefits specific to your project needs.

Environmental Impact and Sustainability

Butyl rubber and halobutyl rubber differ significantly in environmental impact and sustainability, with halobutyl rubber offering enhanced chemical resistance and lower gas permeability, leading to longer product life and reduced waste. Halobutyl rubber's improved durability means fewer replacements, minimizing resource consumption and landfill contributions over time. Choosing halobutyl can enhance your sustainability efforts by supporting materials that promote longer-lasting performance and reduced environmental footprints.

Choosing the Right Rubber for Your Needs

Butyl rubber offers excellent air impermeability and chemical resistance, making it ideal for applications requiring airtight seals and durability, such as inner tubes and protective gloves. Halobutyl rubber, enhanced with halogens, provides superior heat resistance and improved compatibility with adhesives and vulcanization processes, making it suitable for high-performance tire inner liners and pharmaceutical stoppers. Your choice between butyl and halobutyl rubber should consider factors like temperature tolerance, chemical exposure, and bonding requirements to ensure optimal performance.

Butyl rubber vs Halobutyl rubber Infographic

libmatt.com

libmatt.com