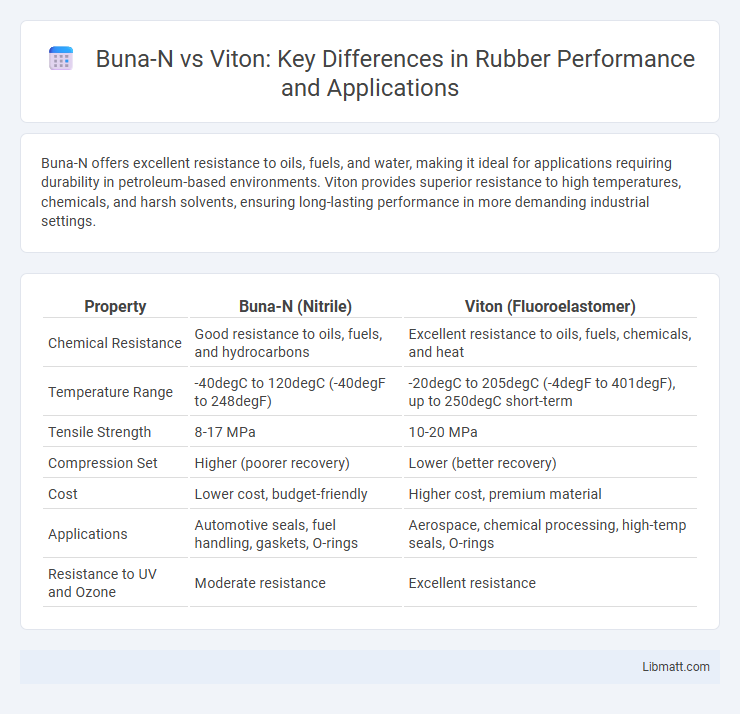

Buna-N offers excellent resistance to oils, fuels, and water, making it ideal for applications requiring durability in petroleum-based environments. Viton provides superior resistance to high temperatures, chemicals, and harsh solvents, ensuring long-lasting performance in more demanding industrial settings.

Table of Comparison

| Property | Buna-N (Nitrile) | Viton (Fluoroelastomer) |

|---|---|---|

| Chemical Resistance | Good resistance to oils, fuels, and hydrocarbons | Excellent resistance to oils, fuels, chemicals, and heat |

| Temperature Range | -40degC to 120degC (-40degF to 248degF) | -20degC to 205degC (-4degF to 401degF), up to 250degC short-term |

| Tensile Strength | 8-17 MPa | 10-20 MPa |

| Compression Set | Higher (poorer recovery) | Lower (better recovery) |

| Cost | Lower cost, budget-friendly | Higher cost, premium material |

| Applications | Automotive seals, fuel handling, gaskets, O-rings | Aerospace, chemical processing, high-temp seals, O-rings |

| Resistance to UV and Ozone | Moderate resistance | Excellent resistance |

Introduction to Buna-N and Viton

Buna-N, also known as Nitrile Rubber, is a synthetic elastomer widely used for its excellent oil, fuel, and chemical resistance, making it ideal for automotive and industrial applications. Viton, a brand of fluorocarbon elastomer, offers superior heat resistance, chemical stability, and durability in harsh environments, often utilized in aerospace and chemical processing industries. Both materials serve critical roles in sealing and gasket applications but differ significantly in temperature tolerance and chemical compatibility.

Chemical Composition and Structure

Buna-N (Nitrile Rubber) is a copolymer of acrylonitrile and butadiene, featuring polar nitrile groups that provide excellent resistance to oils and fuels. Viton, a brand of fluoroelastomer, consists mainly of vinylidene fluoride and hexafluoropropylene, offering superior chemical stability and resistance to high temperatures due to its fluorinated backbone. Your choice between Buna-N and Viton depends on the specific chemical exposure and temperature conditions required for optimal performance.

Temperature Resistance Comparison

Buna-N (Nitrile) typically withstands temperatures ranging from -40degF to 250degF (-40degC to 121degC), making it suitable for moderate heat applications and oil resistance. Viton (FKM) offers superior temperature resistance, performing effectively between -15degF and 400degF (-26degC to 204degC), which makes it ideal for high-temperature environments and aggressive chemical exposure. This significant temperature tolerance difference influences material selection in industries requiring reliable sealing under extreme thermal conditions.

Chemical Compatibility and Resistance

Buna-N (Nitrile) offers excellent resistance to petroleum oils, fuels, and some hydraulic fluids, making it ideal for applications involving hydrocarbons and aliphatic solvents. Viton (FKM) exhibits superior chemical compatibility with aggressive chemicals such as acids, ketones, esters, and aromatic hydrocarbons, providing enhanced resistance to high temperatures and oxidative environments. When selecting materials for seals or gaskets, Viton outperforms Buna-N in chemical resistance for harsh chemicals and extreme conditions, while Buna-N is preferred for cost-effective sealing in less aggressive hydrocarbon environments.

Mechanical Properties and Durability

Buna-N (Nitrile) exhibits excellent resistance to abrasion, tensile strength between 6-11 MPa, and elongation at break around 300-500%, making it suitable for applications requiring flexibility and impact resistance. Viton (Fluorocarbon) offers superior mechanical stability with tensile strength typically in the 9-14 MPa range and elongation at break about 200-300%, coupled with exceptional resistance to high temperatures and chemical degradation. Viton's enhanced durability in harsh environments outperforms Buna-N, especially in exposure to fuels, oils, and solvents, extending service life in demanding automotive and industrial applications.

Applications and Industry Usage

Buna-N (Nitrile) is widely used in automotive fuel systems, oil and gas industries, and general-purpose seals due to its excellent resistance to petroleum-based oils and fuels. Viton (Fluoroelastomer) is preferred in aerospace, chemical processing, and high-temperature applications because of its superior resistance to harsh chemicals, heat, and oxidation. Your choice depends on the operating environment, with Buna-N ideal for moderate temperatures and oil exposure, while Viton excels in more extreme conditions requiring chemical and heat resilience.

Cost and Availability Factors

Buna-N (Nitrile) is significantly more cost-effective and widely available compared to Viton, making it a preferred choice for budget-conscious applications with moderate chemical resistance requirements. Viton, a fluoropolymer elastomer, commands a higher price due to its superior heat, chemical, and oil resistance, but its availability is more limited in general supply channels. Your choice between Buna-N and Viton should consider the balance between upfront material cost and long-term durability in specialized environments.

Performance in Harsh Environments

Buna-N (Nitrile) offers excellent resistance to petroleum oils, fuels, and water, making it suitable for many industrial applications but tends to degrade under high heat or aggressive chemicals. Viton, a fluoroelastomer, excels in extreme temperatures up to 400degF and provides superior chemical resistance against acids, fuels, and solvents. Your choice between Buna-N and Viton should depend on the specific environmental challenges, with Viton being the preferred option for harsher chemical and thermal conditions.

Maintenance and Longevity

Buna-N (Nitrile) offers excellent resistance to oils and fuels, making it ideal for low-cost sealing applications with moderate temperature ranges and easier maintenance due to its abrasion resistance. Viton (Fluoroelastomer) provides superior chemical resistance and high-temperature tolerance, resulting in longer service life in harsh environments and reduced maintenance frequency. Choosing Viton ensures enhanced durability and minimal downtime, while Buna-N suits cost-sensitive uses with less demanding operating conditions.

Choosing Between Buna-N and Viton

Buna-N (Nitrile) offers excellent resistance to petroleum-based oils and fuels, making it ideal for applications in automotive and industrial sectors where exposure to hydraulic fluids and gasoline is common. Viton (Fluorocarbon), however, provides superior resistance to high temperatures, aggressive chemicals, and solvents, which suits aerospace, chemical processing, and high-performance sealing needs. Selecting between Buna-N and Viton depends on factors such as temperature range, chemical compatibility, and cost considerations to ensure optimal durability and performance in specific environments.

Buna-N vs Viton Infographic

libmatt.com

libmatt.com