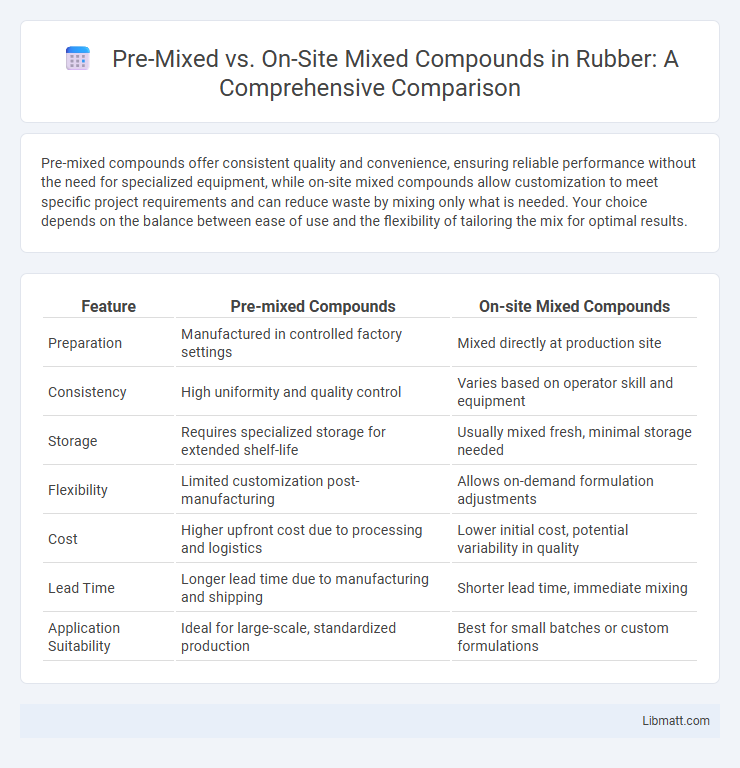

Pre-mixed compounds offer consistent quality and convenience, ensuring reliable performance without the need for specialized equipment, while on-site mixed compounds allow customization to meet specific project requirements and can reduce waste by mixing only what is needed. Your choice depends on the balance between ease of use and the flexibility of tailoring the mix for optimal results.

Table of Comparison

| Feature | Pre-mixed Compounds | On-site Mixed Compounds |

|---|---|---|

| Preparation | Manufactured in controlled factory settings | Mixed directly at production site |

| Consistency | High uniformity and quality control | Varies based on operator skill and equipment |

| Storage | Requires specialized storage for extended shelf-life | Usually mixed fresh, minimal storage needed |

| Flexibility | Limited customization post-manufacturing | Allows on-demand formulation adjustments |

| Cost | Higher upfront cost due to processing and logistics | Lower initial cost, potential variability in quality |

| Lead Time | Longer lead time due to manufacturing and shipping | Shorter lead time, immediate mixing |

| Application Suitability | Ideal for large-scale, standardized production | Best for small batches or custom formulations |

Introduction to Compound Mixing Methods

Pre-mixed compounds offer consistent quality and faster application times, ensuring uniformity in material properties due to factory-controlled processes. On-site mixed compounds allow customization and adaptability for specific project requirements but may introduce variability depending on mixing precision and environmental factors. Selecting the appropriate method depends on factors such as project scale, timing, and desired material characteristics.

What are Pre-mixed Compounds?

Pre-mixed compounds are industrial materials formulated and blended at the manufacturing facility before being shipped to your site, ensuring consistent quality and precise chemical composition. These ready-to-use compounds eliminate the need for on-site mixing equipment and reduce contamination risks, saving time and labor costs during production. Pre-mixed compounds are ideal for applications requiring standardized formulations and reliable performance across various batch sizes.

What are On-site Mixed Compounds?

On-site mixed compounds are formulations prepared directly at the manufacturing location using raw materials tailored to specific production requirements, allowing for greater flexibility and customization. These compounds provide the advantage of adjusting mixtures in real-time to optimize performance, quality, and cost efficiency. Your ability to control the precise formulation enhances product consistency and responsiveness to changing production demands.

Key Differences Between Pre-mixed and On-site Mixed Compounds

Pre-mixed compounds offer consistent formulation and immediate usability, ensuring uniform quality and reducing preparation errors, whereas on-site mixed compounds allow customization and flexibility tailored to specific application requirements. Pre-mixed options streamline processing time and reduce labor costs, while on-site mixing demands skilled personnel and precise measurement to maintain compound integrity. Your choice depends on factors like production volume, quality control standards, and operational capabilities.

Advantages of Pre-mixed Compounds

Pre-mixed compounds offer consistent quality and precise formulation, reducing variability in production processes and mitigating the risk of human error during mixing. They save time and labor costs by eliminating the need for on-site measurement and blending, increasing operational efficiency. Additionally, pre-mixed compounds enhance safety by minimizing exposure to raw chemicals and reducing storage requirements for multiple materials.

Benefits of On-site Mixing

On-site mixed compounds offer superior freshness and customization, allowing precise adjustments to formulation and viscosity, which enhance application efficiency and tailor performance to specific project requirements. This method reduces transportation costs and environmental impact by eliminating the need to ship heavy pre-mixed materials, ensuring cost-effectiveness and sustainability. Immediate availability of freshly mixed compounds minimizes downtime and waste, improving overall productivity on construction or manufacturing sites.

Cost Comparison: Pre-mixed vs On-site Mixed

Pre-mixed compounds often incur higher upfront costs due to factory processing, packaging, and transportation fees, whereas on-site mixed compounds can reduce expenses by eliminating shipping and allowing bulk ingredient purchases. Your overall cost efficiency depends on the scale of usage and labor costs tied to on-site mixing equipment and quality control. Businesses with consistent, high-volume demand may find on-site mixing more economical, while those with variable needs benefit from the convenience and reduced waste of pre-mixed compounds.

Quality Control and Consistency

Pre-mixed compounds offer superior quality control and consistency due to batch-tested formulations produced in controlled factory environments, ensuring uniform performance across applications. On-site mixed compounds can vary in quality and consistency depending on mixing precision, ingredient measurements, and environmental factors, potentially leading to inconsistent product characteristics. Manufacturers and contractors prioritize pre-mixed compounds for standardized results and reduced risk of human error during preparation.

Application Scenarios: Which Method Suits Your Project?

Pre-mixed compounds offer convenience and consistency ideal for small-scale or remote projects with limited equipment, ensuring precise formulation and reduced labor time. On-site mixed compounds suit large-scale or customized projects where adjustments in mixture properties are needed in real-time, providing flexibility and potential cost savings in bulk applications. Choosing between pre-mixed and on-site mixed depends on project size, location, resource availability, and specific material performance requirements.

Conclusion: Choosing the Right Compound Mixing Method

Selecting the appropriate compound mixing method depends on factors such as project scale, cost efficiency, and consistency requirements. Pre-mixed compounds offer convenience and uniform quality, ideal for smaller projects or when time constraints exist. On-site mixed compounds provide customization flexibility and potentially lower costs for large-scale applications, ensuring tailored performance for specific needs.

Pre-mixed vs On-site mixed compounds Infographic

libmatt.com

libmatt.com