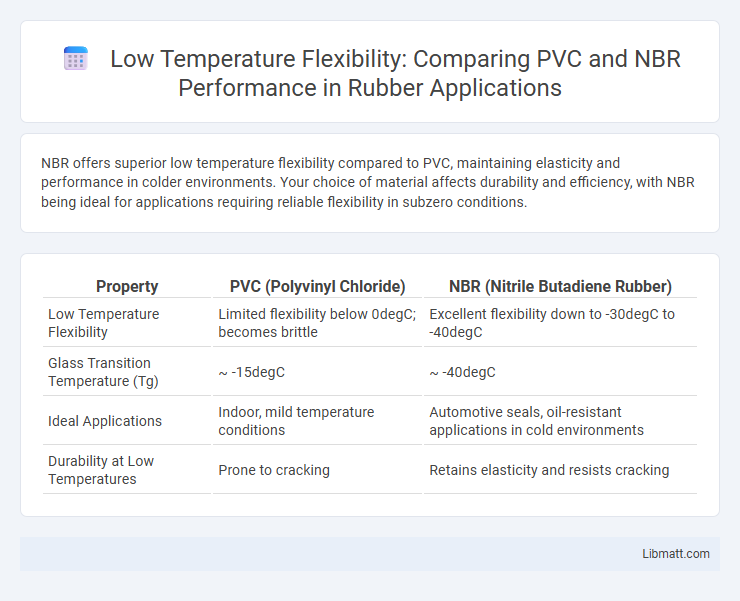

NBR offers superior low temperature flexibility compared to PVC, maintaining elasticity and performance in colder environments. Your choice of material affects durability and efficiency, with NBR being ideal for applications requiring reliable flexibility in subzero conditions.

Table of Comparison

| Property | PVC (Polyvinyl Chloride) | NBR (Nitrile Butadiene Rubber) |

|---|---|---|

| Low Temperature Flexibility | Limited flexibility below 0degC; becomes brittle | Excellent flexibility down to -30degC to -40degC |

| Glass Transition Temperature (Tg) | ~ -15degC | ~ -40degC |

| Ideal Applications | Indoor, mild temperature conditions | Automotive seals, oil-resistant applications in cold environments |

| Durability at Low Temperatures | Prone to cracking | Retains elasticity and resists cracking |

Introduction to Low Temperature Flexibility

Low temperature flexibility refers to the ability of materials like PVC (polyvinyl chloride) and NBR (nitrile butadiene rubber) to maintain elasticity and resist cracking when exposed to cold environments. PVC typically becomes brittle at temperatures below -15degC, limiting its use in extreme cold, whereas NBR exhibits superior low temperature performance, remaining flexible down to approximately -30degC. This makes NBR a preferred choice for applications requiring durability and flexibility in subzero conditions.

Understanding PVC and NBR Materials

PVC offers moderate low temperature flexibility, maintaining performance down to around -15degC, making it suitable for applications requiring rigidity and chemical resistance. NBR excels in low temperature flexibility, remaining pliable at temperatures as low as -40degC, which benefits your needs in environments demanding superior cold resistance and elasticity. Understanding the distinct polymer structures explains why NBR's nitrile content contributes to its enhanced cold flexibility compared to PVC's more rigid vinyl chloride composition.

Importance of Low Temperature Flexibility in Applications

Low temperature flexibility is crucial in applications where materials must withstand extreme cold without cracking or losing elasticity, such as in automotive seals and outdoor equipment. PVC typically becomes rigid and brittle at low temperatures, limiting its use in cold environments, whereas NBR (Nitrile Butadiene Rubber) maintains its flexibility down to much lower temperatures, enhancing durability and performance. Understanding these differences ensures Your choice of material will withstand harsh conditions while maintaining functionality.

PVC: Low Temperature Performance Overview

PVC exhibits moderate low temperature flexibility, typically becoming brittle below -15degC, which limits its use in extremely cold environments. Its rigid molecular structure reduces elasticity at low temperatures, affecting durability and performance in applications requiring flexibility. You should consider alternatives like NBR if superior flexibility and resilience are needed in colder conditions.

NBR: Low Temperature Performance Overview

NBR (Nitrile Butadiene Rubber) exhibits superior low temperature flexibility compared to PVC (Polyvinyl Chloride), maintaining elasticity and resilience at temperatures as low as -40degC. This makes NBR ideal for applications in cold climates or where extreme temperature fluctuations occur. Its molecular structure allows NBR to resist stiffness and cracking, outperforming PVC in low temperature environments.

Comparative Analysis: PVC vs NBR Flexibility

NBR exhibits superior low temperature flexibility compared to PVC, maintaining pliability down to -30degC, whereas PVC typically becomes brittle below -10degC. This enhanced elasticity of NBR at subzero temperatures makes it ideal for applications requiring reliable performance in cold environments. PVC, while chemically resistant, is less suited for dynamic flexing in low temperature conditions due to its rigid molecular structure.

Factors Influencing Flexibility at Low Temperatures

Low temperature flexibility in PVC and NBR is influenced by polymer composition, glass transition temperature (Tg), and plasticizer content. PVC typically has a higher Tg around 80degC, making it less flexible at subzero temperatures, while NBR has a significantly lower Tg ranging from -30degC to -50degC, enhancing its pliability in cold environments. The presence and type of plasticizers in both materials modulate molecular mobility, with NBR's nitrile groups providing superior resistance to cold brittleness compared to the rigid PVC backbone.

Typical Industry Applications Requiring Flexibility

Low temperature flexibility is critical for industries where materials endure cold environments, such as automotive, oil and gas, and cold storage sectors. PVC typically serves applications requiring chemical resistance and durability but may become brittle below -15degC, limiting its use in low-temperature conditions. NBR excels in applications needing strong oil resistance and flexibility down to -40degC, making it suitable for seals, hoses, and gaskets in cold climates.

Pros and Cons: PVC vs NBR in Cold Environments

PVC exhibits limited low temperature flexibility, becoming brittle below -15degC, which restricts its use in cold environments; however, it maintains good chemical resistance and cost-effectiveness. NBR (Nitrile Butadiene Rubber) remains flexible down to approximately -40degC, offering superior performance in extreme cold but has lower resistance to ozone and weathering compared to PVC. Your choice depends on balancing flexibility needs in sub-zero conditions against durability and chemical exposure requirements.

Conclusion: Choosing the Right Material for Low Temperature Conditions

NBR excels in low temperature flexibility, maintaining elasticity and performance down to around -40degC, whereas PVC typically becomes rigid below -20degC, risking cracking. Your application requires NBR when elasticity and durability in cold environments are critical, making it the superior choice. PVC suits moderate conditions but lacks the resilience needed for extreme low temperatures.

Low temperature flexibility: PVC vs NBR Infographic

libmatt.com

libmatt.com