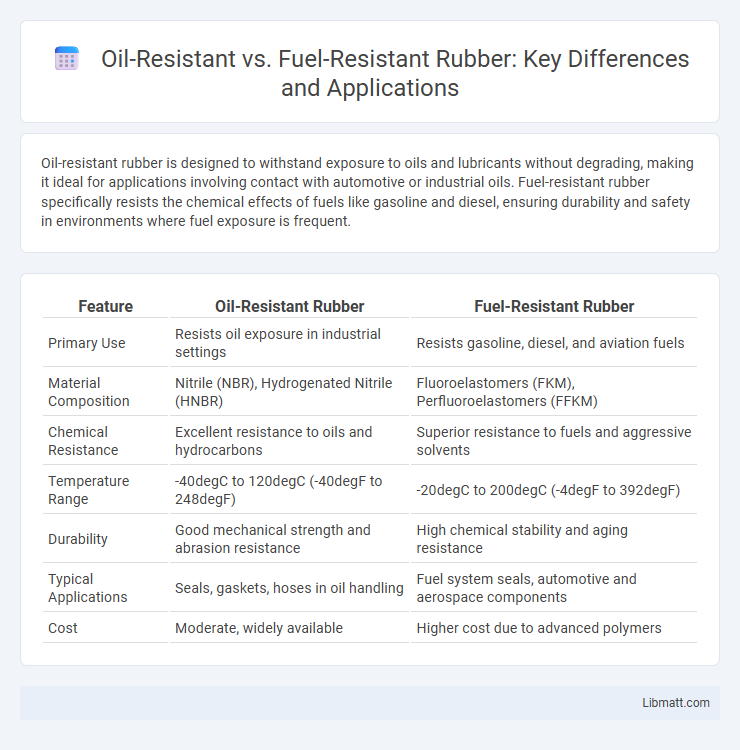

Oil-resistant rubber is designed to withstand exposure to oils and lubricants without degrading, making it ideal for applications involving contact with automotive or industrial oils. Fuel-resistant rubber specifically resists the chemical effects of fuels like gasoline and diesel, ensuring durability and safety in environments where fuel exposure is frequent.

Table of Comparison

| Feature | Oil-Resistant Rubber | Fuel-Resistant Rubber |

|---|---|---|

| Primary Use | Resists oil exposure in industrial settings | Resists gasoline, diesel, and aviation fuels |

| Material Composition | Nitrile (NBR), Hydrogenated Nitrile (HNBR) | Fluoroelastomers (FKM), Perfluoroelastomers (FFKM) |

| Chemical Resistance | Excellent resistance to oils and hydrocarbons | Superior resistance to fuels and aggressive solvents |

| Temperature Range | -40degC to 120degC (-40degF to 248degF) | -20degC to 200degC (-4degF to 392degF) |

| Durability | Good mechanical strength and abrasion resistance | High chemical stability and aging resistance |

| Typical Applications | Seals, gaskets, hoses in oil handling | Fuel system seals, automotive and aerospace components |

| Cost | Moderate, widely available | Higher cost due to advanced polymers |

Introduction to Oil-Resistant and Fuel-Resistant Rubber

Oil-resistant rubber is engineered to withstand degradation from exposure to oils, lubricants, and similar hydrocarbon-based substances, maintaining elasticity and strength in automotive and industrial applications. Fuel-resistant rubber specifically resists the harsh chemical effects of gasoline, diesel, and other fuel types, preventing swelling, cracking, and loss of performance in fuel systems. Understanding the differences helps you select the appropriate material for seals, hoses, and gaskets that operate in distinct oil or fuel environments.

Key Differences Between Oil-Resistant and Fuel-Resistant Rubber

Oil-resistant rubber is specifically formulated to withstand exposure to various oils, maintaining flexibility and structural integrity without degrading, while fuel-resistant rubber is designed to resist damage and swelling caused by fuels like gasoline and diesel. The primary difference lies in their chemical composition; oil-resistant rubber typically contains nitrile or neoprene compounds, whereas fuel-resistant varieties often use fluorocarbon or hydrogenated nitrile to provide enhanced resistance to aggressive hydrocarbons. Understanding these distinctions helps you select the appropriate material for applications where exposure to specific liquids demands targeted durability.

Chemical Composition and Structure

Oil-resistant rubber typically contains polymers like nitrile butadiene rubber (NBR) with polar nitrile groups that enhance resistance to hydrocarbons and oils. Fuel-resistant rubber often incorporates fluorocarbon polymers such as Viton (FKM), which have a unique fluorine atom structure providing superior resistance to aggressive fuels and solvents. The chemical composition and molecular structure differences determine their specific compatibility and durability in various chemical environments.

Types of Oil-Resistant Rubber Compounds

Oil-resistant rubber compounds primarily include nitrile butadiene rubber (NBR), hydrogenated nitrile butadiene rubber (HNBR), and fluorocarbon rubber (FKM), each offering varying degrees of resistance to oils, fuels, and hydrocarbons. NBR is widely used for its excellent resistance to petroleum-based oils and fuels, while HNBR provides enhanced heat and chemical durability for more demanding applications. FKM compounds deliver superior performance in aggressive chemical environments, including exposure to synthetic oils and high-temperature fuels.

Types of Fuel-Resistant Rubber Compounds

Fuel-resistant rubber compounds include nitrile rubber (NBR), fluoroelastomers (FKM), and hydrogenated nitrile butadiene rubber (HNBR), each offering distinct levels of resistance to fuels and oils. NBR is highly effective against petroleum-based fuels, while FKM provides superior chemical and high-temperature resistance, making it ideal for more aggressive fuel types. Your choice depends on the specific fuel exposure and operating conditions required for optimal performance and durability.

Common Applications in Industry

Oil-resistant rubber is widely used in automotive seals, gaskets, and hoses exposed to lubricants, providing durability against oils and greases. Fuel-resistant rubber finds common applications in fuel lines, fuel tanks, and injector seals where exposure to hydrocarbons and gasoline is critical. Your choice between these materials depends on the specific chemical environment and performance requirements in industry settings.

Performance Under Harsh Conditions

Oil-resistant rubber offers superior durability against petroleum-based substances, maintaining elasticity and strength when exposed to oils and lubricants. Fuel-resistant rubber, however, is specifically formulated to withstand aggressive hydrocarbons like gasoline and diesel, preventing swelling, cracking, and degradation during extended contact. Your choice between these materials depends on the specific harsh chemical environment and performance requirements for resistance and longevity.

Advantages and Limitations of Each Rubber Type

Oil-resistant rubber offers superior durability and flexibility when exposed to hydraulic oils, mineral oils, and lubricants, making it ideal for automotive and industrial seals; however, it can degrade when in contact with aromatic hydrocarbons and certain solvents. Fuel-resistant rubber excels in withstanding exposure to gasoline, diesel, and ethanol blends, providing excellent chemical resistance and longevity in fuel system components, but it often lacks the mechanical flexibility and temperature tolerance of oil-resistant variants. Selecting between these rubbers depends on specific fluid compatibility, operating temperature, and application demands.

Selection Criteria for Industrial Use

Oil-resistant rubber is ideal for applications exposed primarily to petroleum-based oils, offering excellent durability against hydrocarbon degradation, while fuel-resistant rubber is formulated to withstand a broader range of aggressive fuels and chemical compounds. Your selection criteria should include the specific type of fluids in contact, operating temperature ranges, mechanical stress, and expected lifespan to ensure optimal performance and cost-effectiveness. Testing material compatibility and consulting industry standards like ASTM D2000 can further guide you in choosing the most suitable rubber type for industrial use.

Future Trends in Oil and Fuel-Resistant Rubber Technology

Advancements in oil-resistant rubber focus on enhancing durability against hydrocarbon exposure and extreme temperatures, incorporating nanocomposites and bio-based materials for improved sustainability. Fuel-resistant rubber technology is progressing with the development of specialized polymers that offer superior resistance to diverse fuel types, including biofuels and synthetic fuels, ensuring longer service life and better performance. Your selection of these materials will benefit from innovations aimed at reducing environmental impact while boosting resistance to harsh chemical environments in automotive and industrial applications.

Oil-Resistant Rubber vs Fuel-Resistant Rubber Infographic

libmatt.com

libmatt.com