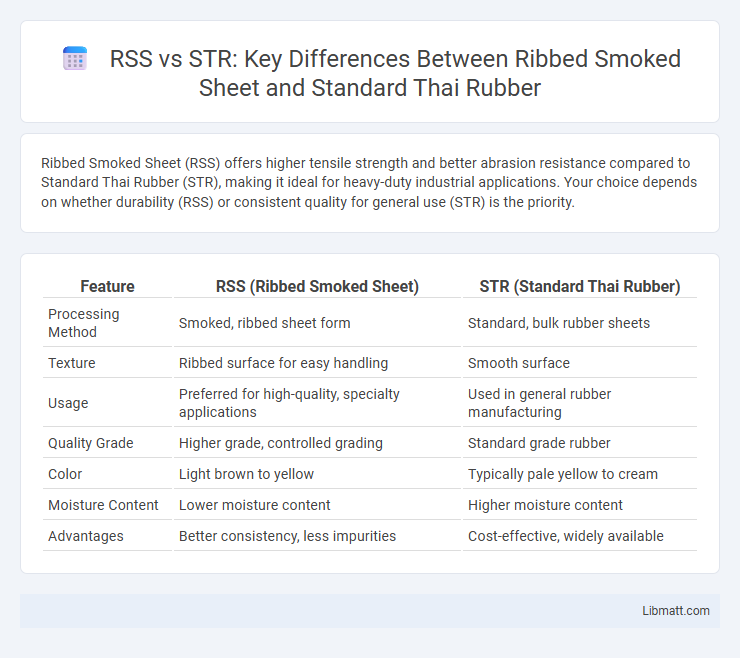

Ribbed Smoked Sheet (RSS) offers higher tensile strength and better abrasion resistance compared to Standard Thai Rubber (STR), making it ideal for heavy-duty industrial applications. Your choice depends on whether durability (RSS) or consistent quality for general use (STR) is the priority.

Table of Comparison

| Feature | RSS (Ribbed Smoked Sheet) | STR (Standard Thai Rubber) |

|---|---|---|

| Processing Method | Smoked, ribbed sheet form | Standard, bulk rubber sheets |

| Texture | Ribbed surface for easy handling | Smooth surface |

| Usage | Preferred for high-quality, specialty applications | Used in general rubber manufacturing |

| Quality Grade | Higher grade, controlled grading | Standard grade rubber |

| Color | Light brown to yellow | Typically pale yellow to cream |

| Moisture Content | Lower moisture content | Higher moisture content |

| Advantages | Better consistency, less impurities | Cost-effective, widely available |

Introduction to RSS and STR

Ribbed Smoked Sheet (RSS) and Standard Thai Rubber (STR) are two primary types of natural rubber widely used in industrial applications. RSS is characterized by its ribbed texture and is produced through a specific smoking process that enhances durability and quality. In contrast, STR refers to a standardized grade of latex rubber that is typically processed into sheets or crepes, known for consistent purity and reliable performance in manufacturing.

Understanding Ribbed Smoked Sheet (RSS)

Ribbed Smoked Sheet (RSS) is a form of natural rubber processed by coagulating latex into sheets with ribbed surfaces to enhance drying and improve quality. The ribs on RSS facilitate uniform smoke penetration, which provides better preservation, increased tensile strength, and resistance to dirt compared to Standard Thai Rubber (STR). RSS's unique preparation method makes it highly sought after in industries requiring durable and high-quality rubber materials.

Overview of Standard Thai Rubber (STR)

Standard Thai Rubber (STR) is a primary form of natural rubber widely used in industrial applications due to its consistent quality and high purity. STR is produced through a standardized coagulation process, ensuring uniform ribbed sheets ideal for manufacturing tires, gloves, and adhesives. Your choice of STR guarantees reliable performance and compatibility with diverse rubber processing technologies.

Production Processes: RSS vs STR

Production of Ribbed Smoked Sheet (RSS) involves coagulating latex into sheets which are then subjected to a smoking process over several days to enhance durability and resistance to microbial attack. Standard Thai Rubber (STR) production differentiates itself by employing centrifugation to extract dry rubber content from latex, resulting in a granular product that requires minimal further processing. The smoking in RSS improves physical properties such as tensile strength, whereas the centrifugation in STR focuses on purity and uniformity, affecting subsequent usage in manufacturing.

Key Physical and Chemical Differences

RSS (Ribbed Smoked Sheet) features a unique ribbed surface providing higher tensile strength and better abrasion resistance compared to STR (Standard Thai Rubber), which has a smoother texture and more uniform thickness. Chemically, RSS contains lower protein and ash content, resulting in enhanced purity and elasticity, whereas STR typically exhibits higher nitrogen content influencing vulcanization properties. Your choice between RSS and STR impacts product durability and performance in rubber manufacturing applications.

Quality Grades and Standardization

RSS (Ribbed Smoked Sheet) offers higher quality grades characterized by uniform thickness and minimal impurities, enhancing its consistency and durability in manufacturing. Standard Thai Rubber (STR) follows stringent classification protocols, with grades like STR 20 and STR 10 standardized based on viscosity and ash content to ensure reliability for industrial use. Understanding these distinctions helps you select the appropriate rubber grade tailored to specific performance and quality standards in rubber products.

Applications and End Uses

Ribbed Smoked Sheet (RSS) is primarily used in high-quality tire manufacturing, footwear, and industrial products due to its superior tensile strength and uniformity, making it ideal for applications requiring enhanced durability and elasticity. Standard Thai Rubber (STR) is widely applied in general rubber goods such as mats, gloves, and automotive parts, favored for its consistent purity and cost-effectiveness in mass production. Both RSS and STR serve the rubber industry but target distinct end uses based on their physical properties, with RSS preferred for performance-critical components and STR for everyday rubber products.

Pricing and Market Factors

RSS (Ribbed Smoked Sheet) typically commands higher prices than STR (Standard Thai Rubber) due to its superior quality and enhanced durability, making it preferred for manufacturing high-end rubber products. Market factors such as global demand, production costs, and export policies in Thailand influence pricing fluctuations for both RSS and STR. Your choice between RSS and STR should consider cost-effectiveness and specific application requirements in the rubber industry.

Environmental and Sustainability Considerations

Ribbed Smoked Sheet (RSS) production relies on natural rubber extraction and traditional processing methods that demand sustainable tapping practices to minimize environmental impact, while Standard Thai Rubber (STR) utilizes centrifugation techniques, resulting in less waste and reduced water consumption. You should consider that RSS involves smoke drying, which emits some pollutants, whereas STR's more mechanized process generally offers better emission controls and energy efficiency. Choosing between RSS and STR depends on your prioritization of eco-friendly raw material sourcing versus industrial sustainability measures.

Choosing Between RSS and STR: Factors to Consider

Choosing between Ribbed Smoked Sheet (RSS) and Standard Thai Rubber (STR) depends on specific application requirements such as product durability, processing methods, and quality standards. RSS, known for its higher purity and consistent ribbed texture, is ideal for products demanding superior tensile strength and uniformity, while STR offers greater flexibility due to its general-grade form and is often used in mass production where cost-effectiveness is critical. Factors like end-use performance, processing compatibility, and budget constraints play pivotal roles in selecting the most suitable rubber grade.

RSS vs STR (Ribbed Smoked Sheet vs Standard Thai Rubber) Infographic

libmatt.com

libmatt.com