HNBR offers superior heat, oil, and chemical resistance compared to NBR, making it ideal for demanding automotive and industrial applications. Your choice between HNBR and NBR depends on the specific environmental conditions and performance requirements of your project.

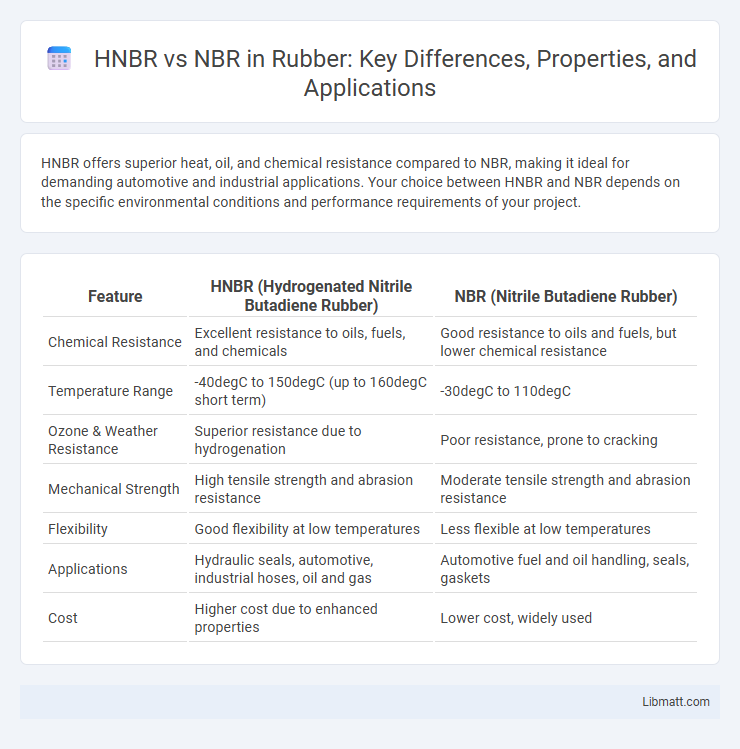

Table of Comparison

| Feature | HNBR (Hydrogenated Nitrile Butadiene Rubber) | NBR (Nitrile Butadiene Rubber) |

|---|---|---|

| Chemical Resistance | Excellent resistance to oils, fuels, and chemicals | Good resistance to oils and fuels, but lower chemical resistance |

| Temperature Range | -40degC to 150degC (up to 160degC short term) | -30degC to 110degC |

| Ozone & Weather Resistance | Superior resistance due to hydrogenation | Poor resistance, prone to cracking |

| Mechanical Strength | High tensile strength and abrasion resistance | Moderate tensile strength and abrasion resistance |

| Flexibility | Good flexibility at low temperatures | Less flexible at low temperatures |

| Applications | Hydraulic seals, automotive, industrial hoses, oil and gas | Automotive fuel and oil handling, seals, gaskets |

| Cost | Higher cost due to enhanced properties | Lower cost, widely used |

Introduction to HNBR and NBR

HNBR (Hydrogenated Nitrile Butadiene Rubber) is a synthetic elastomer known for its enhanced resistance to heat, ozone, and chemicals compared to NBR (Nitrile Butadiene Rubber). NBR is widely used for its strong oil and fuel resistance, making it a common choice in automotive and industrial sealing applications. The hydrogenation process in HNBR saturates the polymer bonds, improving durability and performance in harsher environments relative to standard NBR.

Chemical Structure Comparison

HNBR (Hydrogenated Nitrile Butadiene Rubber) features a saturated carbon chain achieved through hydrogenation of the double bonds present in the NBR (Nitrile Butadiene Rubber) polymer backbone, resulting in enhanced resistance to heat, oxidation, and ozone. The chemical structure of NBR consists of copolymerized acrylonitrile and butadiene units with unsaturated double bonds, making it more prone to degradation under harsh environments. This structural difference gives HNBR superior mechanical properties and chemical stability compared to standard NBR, especially in high-temperature and aggressive chemical applications.

Key Physical Properties

HNBR exhibits superior heat resistance, maintaining excellent mechanical properties at temperatures up to 150degC, while NBR typically withstands temperatures up to 100degC. HNBR offers enhanced chemical resistance and greater tensile strength, making it more durable in harsh environments compared to NBR, which is more susceptible to swelling in oils. Your choice between HNBR and NBR should consider these key physical properties for optimal performance in temperature and chemical exposure conditions.

Temperature Resistance

HNBR (Hydrogenated Nitrile Butadiene Rubber) exhibits superior temperature resistance compared to NBR (Nitrile Butadiene Rubber), maintaining stability in continuous operating temperatures up to 150degC and short-term exposures reaching 165degC. NBR generally withstands temperatures up to 100degC during continuous use but degrades faster under higher thermal stress. This enhanced heat resistance makes HNBR ideal for automotive, oil, and industrial applications requiring prolonged exposure to elevated temperatures.

Oil and Chemical Compatibility

HNBR (Hydrogenated Nitrile Butadiene Rubber) exhibits superior oil and chemical compatibility compared to standard NBR (Nitrile Butadiene Rubber), making it ideal for applications involving aggressive oils, fuels, and chemicals. Its hydrogenation process enhances resistance to heat, ozone, and swelling in aromatic hydrocarbons and acids, extending seal and gasket lifespans. NBR remains suitable for general oil resistance but degrades faster under exposure to harsh chemical environments where HNBR excels.

Mechanical Strength and Durability

HNBR (Hydrogenated Nitrile Butadiene Rubber) offers superior mechanical strength and enhanced durability compared to standard NBR (Nitrile Butadiene Rubber), thanks to its improved resistance to heat, ozone, and chemical exposure. Your choice of HNBR ensures better performance in demanding environments where long-lasting elastomeric materials are critical. This makes HNBR ideal for applications requiring excellent tensile strength, abrasion resistance, and extended service life.

Common Applications

HNBR (Hydrogenated Nitrile Butadiene Rubber) is widely used in automotive fuel systems, seals, and O-rings due to its superior heat, chemical, and oil resistance compared to standard NBR (Nitrile Butadiene Rubber). NBR is commonly applied in oil seals, gaskets, and hoses, particularly in low to moderate temperature environments where resistance to oils and fuels is essential. Both materials are popular in industrial and automotive sectors, but HNBR is preferred for high-temperature and more chemically aggressive applications.

Cost and Availability

HNBR (Hydrogenated Nitrile Butadiene Rubber) generally costs more than standard NBR (Nitrile Butadiene Rubber) due to enhanced chemical and temperature resistance properties. NBR is widely available in the market and often chosen for budget-sensitive applications, while HNBR's availability may be more limited and targeted towards specialized industrial uses. Cost differences reflect HNBR's superior durability and performance in harsh environments compared to the more common NBR.

Environmental and Safety Factors

HNBR (Hydrogenated Nitrile Butadiene Rubber) offers superior resistance to ozone, heat, and chemical degradation compared to standard NBR (Nitrile Butadiene Rubber), making it more environmentally stable and safer for use in harsh conditions. Its enhanced durability reduces the frequency of replacements, minimizing waste and environmental impact in industrial applications. Your choice of HNBR ensures improved safety performance, especially in automotive and aerospace seals exposed to aggressive fluids and extreme temperatures.

Choosing Between HNBR and NBR

Choosing between HNBR (Hydrogenated Nitrile Butadiene Rubber) and NBR (Nitrile Butadiene Rubber) depends on temperature resistance, chemical compatibility, and durability requirements. HNBR offers superior heat resistance, retaining flexibility up to 150degC, making it ideal for automotive and industrial applications exposed to high temperatures. NBR provides excellent resistance to oils and fuels at moderate temperatures but degrades faster under extreme thermal stress, making it suitable for general-purpose seals and gaskets.

HNBR vs NBR Infographic

libmatt.com

libmatt.com