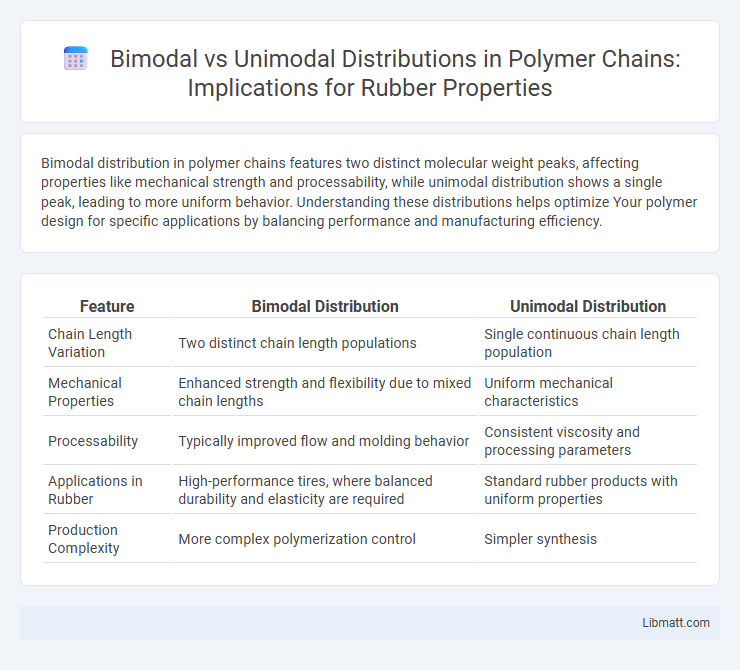

Bimodal distribution in polymer chains features two distinct molecular weight peaks, affecting properties like mechanical strength and processability, while unimodal distribution shows a single peak, leading to more uniform behavior. Understanding these distributions helps optimize Your polymer design for specific applications by balancing performance and manufacturing efficiency.

Table of Comparison

| Feature | Bimodal Distribution | Unimodal Distribution |

|---|---|---|

| Chain Length Variation | Two distinct chain length populations | Single continuous chain length population |

| Mechanical Properties | Enhanced strength and flexibility due to mixed chain lengths | Uniform mechanical characteristics |

| Processability | Typically improved flow and molding behavior | Consistent viscosity and processing parameters |

| Applications in Rubber | High-performance tires, where balanced durability and elasticity are required | Standard rubber products with uniform properties |

| Production Complexity | More complex polymerization control | Simpler synthesis |

Introduction to Polymer Chain Distributions

Polymer chain distributions describe the variation in molecular weights within a polymer sample, crucial for determining material properties. Unimodal distribution features a single, dominant molecular weight peak, leading to more uniform chain lengths and predictable mechanical characteristics. Bimodal distribution consists of two distinct molecular weight peaks, offering enhanced processing flexibility and improved performance by combining properties of both low- and high-molecular-weight chains in Your polymer matrix.

Defining Unimodal Distribution in Polymers

Unimodal distribution in polymers refers to a molecular weight distribution characterized by a single, distinct peak, indicating uniform polymer chain lengths within the sample. This distribution is crucial for applications requiring consistent physical properties, such as tensile strength and viscosity, due to the homogeneous chain length. The unimodal molecular weight distribution is typically quantified using techniques like gel permeation chromatography (GPC), which provides precise measurements of polymer chain length uniformity.

Understanding Bimodal Distribution in Polymer Chains

Bimodal distribution in polymer chains refers to the presence of two distinct molecular weight populations within a single polymer sample, enhancing material properties such as strength and processability. Understanding this distribution allows you to tailor polymer characteristics by balancing low and high molecular weight fractions, optimizing viscosity and mechanical performance. Unlike unimodal distributions, which consist of a single, uniform molecular weight, bimodal polymers improve blend homogeneity and enable better end-use applications in packaging and automotive industries.

Key Differences: Bimodal vs Unimodal Distributions

Bimodal distributions in polymer chains feature two distinct molecular weight peaks, representing a mixture of low and high molecular weight fractions, whereas unimodal distributions exhibit a single, continuous peak indicating a more uniform polymer size. This dual-peak characteristic in bimodal polymers enhances material properties such as strength and processability by combining the advantages of different chain lengths. Unimodal distributions, with their narrow molecular weight range, typically offer consistent mechanical properties and predictable processing behavior.

Methods for Analyzing Polymer Chain Distributions

Gel permeation chromatography (GPC) stands as a primary method for distinguishing bimodal and unimodal polymer chain distributions by measuring molecular weight distributions through size exclusion principles. Nuclear magnetic resonance (NMR) spectroscopy complements GPC by providing insights into the chemical structure and branching, assisting in identifying distribution modalities. Light scattering techniques, including multi-angle light scattering (MALS), enable precise molecular weight and size determination, enhancing differentiation between unimodal and bimodal polymer distributions.

Effects on Polymer Properties: Unimodal vs Bimodal

Unimodal polymer chain distributions exhibit consistent molecular weights, resulting in predictable mechanical properties and uniform processing behavior. Bimodal distributions combine low and high molecular weight chains, enhancing toughness and processability by balancing strength and flow characteristics. This dual distribution improves impact resistance and reduces viscosity compared to unimodal polymers, optimizing performance for industrial applications.

Applications of Bimodal Polymer Distributions

Bimodal polymer distributions offer enhanced mechanical properties and processability compared to unimodal distributions, making them ideal for applications such as injection molding, blow molding, and extrusion where toughness and flow behavior are critical. The presence of both low and high molecular weight fractions in bimodal polymers improves melt strength and impact resistance, benefiting industries like automotive, packaging, and consumer goods. Your choice of bimodal polymers can optimize performance in components requiring a balance between stiffness and flexibility.

Industrial Relevance of Unimodal Polymers

Unimodal polymer distributions provide consistent molecular weight profiles that enhance processability and mechanical properties in industrial applications, ensuring predictable performance in manufacturing environments. These polymers are favored for producing uniform materials with reliable strength, durability, and viscosity, crucial for sectors like packaging, automotive, and consumer goods. Your choice of unimodal polymers supports streamlined production workflows and high-quality end products due to their narrow molecular weight dispersity.

Challenges in Synthesizing Bimodal and Unimodal Polymers

Synthesizing bimodal polymer chains involves challenges in precisely controlling molecular weight distribution to achieve two distinct peaks, which requires advanced polymerization techniques and stringent reaction conditions. Unimodal polymers demand uniform reaction rates and consistent catalyst activity to maintain a narrow, single-peaked molecular weight distribution, making scalability and reproducibility key difficulties. Your ability to optimize polymer properties depends heavily on overcoming these synthesis challenges to tailor molecular architecture effectively.

Future Trends in Polymer Distribution Research

Future trends in polymer distribution research emphasize the design and control of bimodal versus unimodal molecular weight distributions to enhance polymer performance and processing. Advanced characterization techniques and machine learning models are employed to predict and tailor polymer chain architectures, optimizing properties such as strength, flexibility, and durability. Your ability to leverage these innovations will drive the development of next-generation polymers with customized distribution profiles for specific industrial applications.

Bimodal vs Unimodal distribution in polymer chains Infographic

libmatt.com

libmatt.com