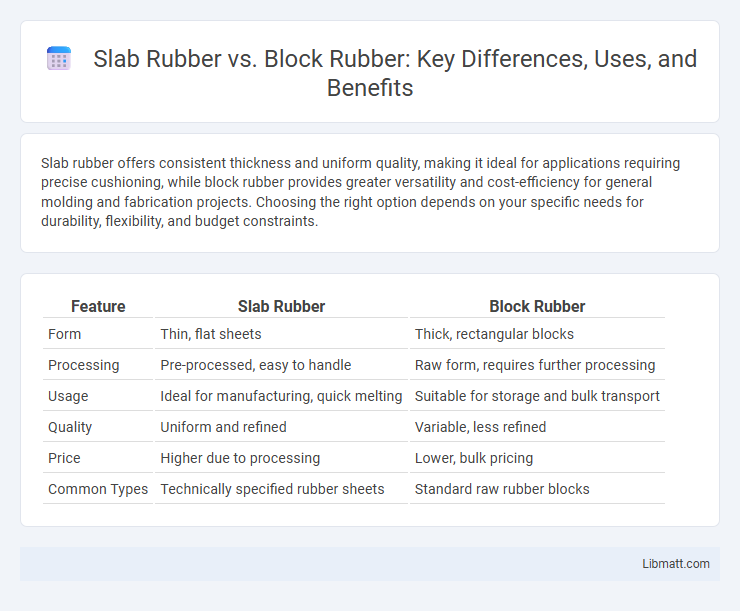

Slab rubber offers consistent thickness and uniform quality, making it ideal for applications requiring precise cushioning, while block rubber provides greater versatility and cost-efficiency for general molding and fabrication projects. Choosing the right option depends on your specific needs for durability, flexibility, and budget constraints.

Table of Comparison

| Feature | Slab Rubber | Block Rubber |

|---|---|---|

| Form | Thin, flat sheets | Thick, rectangular blocks |

| Processing | Pre-processed, easy to handle | Raw form, requires further processing |

| Usage | Ideal for manufacturing, quick melting | Suitable for storage and bulk transport |

| Quality | Uniform and refined | Variable, less refined |

| Price | Higher due to processing | Lower, bulk pricing |

| Common Types | Technically specified rubber sheets | Standard raw rubber blocks |

Introduction to Slab Rubber and Block Rubber

Slab rubber and block rubber are key forms of natural rubber used in various industries for manufacturing and processing. Slab rubber is a thin, flat sheet obtained by coagulating latex, ideal for quick melting and molding, whereas block rubber is a denser, compressed form typically used for more durable applications. Understanding the differences between slab and block rubber can help you select the right material based on flexibility, processing speed, and end-use requirements.

Defining Slab Rubber: Characteristics and Uses

Slab rubber is a form of natural rubber processed into thick, flat sheets primarily used in manufacturing and industrial applications due to its uniform thickness and high tensile strength. It exhibits excellent elasticity, resilience, and resistance to abrasion, making it ideal for producing rubber goods such as tires, conveyor belts, and automotive components. This material's consistent quality and ease of handling distinguish it from block rubber, which is solid and less processed, often requiring further refinement before use.

Understanding Block Rubber: Features and Applications

Block rubber consists of natural rubber latex coagulated and pressed into dense, solid blocks, offering high purity and consistent quality. It is widely used in manufacturing industries for producing tires, footwear, and rubber goods due to its superior elasticity, abrasion resistance, and ease of processing. Your choice of block rubber ensures durability and performance in applications requiring strong, flexible material with reliable chemical stability.

Production Processes: Slab Rubber vs Block Rubber

Slab rubber is produced by mixing raw rubber with chemicals and additives, then sheeting it into flat, thin layers using two-roll mills or calendar machines. Block rubber undergoes a similar compounding process but is shaped into larger, thicker blocks through pressing or molding methods, allowing for easier storage and transportation. The key difference lies in the final form and thickness, with slab rubber being more flexible for immediate processing, while block rubber is better suited for longer-term storage and bulk handling.

Key Differences in Physical Properties

Slab rubber features a smooth, flexible surface that allows for easy cutting and shaping, making it ideal for applications requiring precise dimensions and cushioning. Block rubber is denser and more rigid with a rougher texture, providing enhanced durability and resistance to wear in heavy-duty industrial uses. Your choice depends on whether flexibility or toughness is the priority for your specific rubber application.

Industrial Applications: Where Each Type Excels

Slab rubber is ideal for industrial applications requiring large, uniform sheets, such as conveyor belts, flooring, and vibration dampening, due to its consistent thickness and flexibility. Block rubber excels in sectors needing customizable shapes and sizes, like automotive parts, gaskets, and molded components, because it can be easily cut and processed into specific forms. Each type supports diverse manufacturing needs, optimizing performance based on application-specific demands.

Cost Comparison and Market Availability

Slab rubber is generally more expensive than block rubber due to its higher purity and processing standards, making it preferred for premium applications. Block rubber dominates the market in terms of availability because it is easier to produce and widely used in industrial manufacturing. Price fluctuations in both types are influenced by natural rubber supply, global demand, and regional production capacities.

Environmental Impact and Sustainability

Slab rubber production generates less waste compared to block rubber, making it a more eco-friendly choice for manufacturers aiming to reduce environmental impact. The energy consumption in producing slab rubber is generally lower, contributing to a smaller carbon footprint. By choosing slab rubber, you support sustainable practices that promote efficient resource use and waste minimization in the rubber industry.

Quality Standards and Certification

Slab rubber and block rubber differ significantly in quality standards and certification, with slab rubber often adhering to stricter ISO and ASTM certifications due to its refined processing methods. Block rubber may have variable quality levels depending on its manufacturing origin, and it typically requires additional testing to meet international standards for industrial use. Understanding these certifications ensures your rubber products meet performance and safety requirements critical for specific applications.

Choosing Between Slab Rubber and Block Rubber

Choosing between slab rubber and block rubber depends on your specific application requirements, such as processing convenience and material consistency. Slab rubber offers uniform thickness and is easier to handle for continuous mixing or molding, while block rubber provides greater flexibility for custom sizing and diverse manufacturing needs. Your decision should consider factors like production scale, ease of storage, and the type of rubber compound needed for optimal performance.

Slab Rubber vs Block Rubber Infographic

libmatt.com

libmatt.com