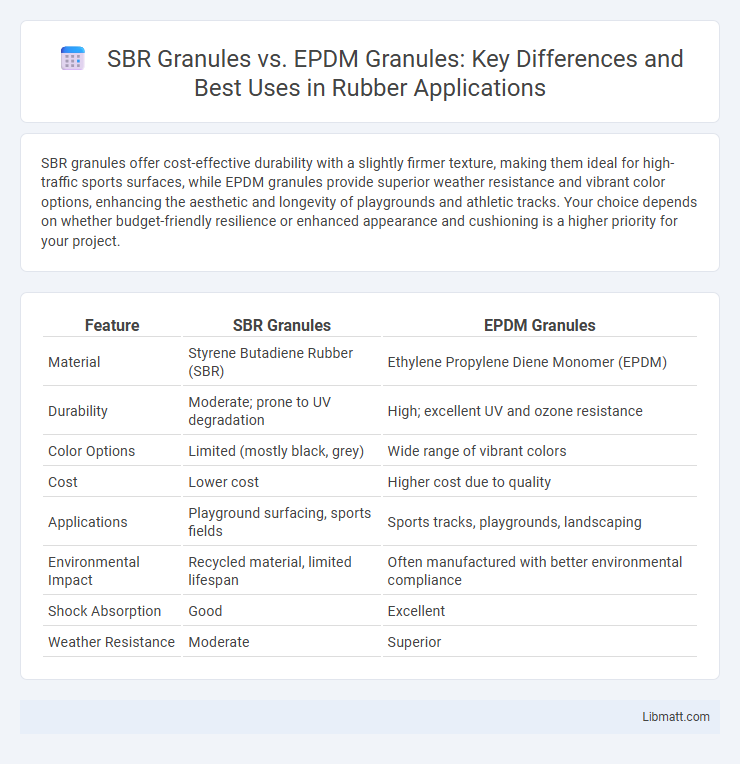

SBR granules offer cost-effective durability with a slightly firmer texture, making them ideal for high-traffic sports surfaces, while EPDM granules provide superior weather resistance and vibrant color options, enhancing the aesthetic and longevity of playgrounds and athletic tracks. Your choice depends on whether budget-friendly resilience or enhanced appearance and cushioning is a higher priority for your project.

Table of Comparison

| Feature | SBR Granules | EPDM Granules |

|---|---|---|

| Material | Styrene Butadiene Rubber (SBR) | Ethylene Propylene Diene Monomer (EPDM) |

| Durability | Moderate; prone to UV degradation | High; excellent UV and ozone resistance |

| Color Options | Limited (mostly black, grey) | Wide range of vibrant colors |

| Cost | Lower cost | Higher cost due to quality |

| Applications | Playground surfacing, sports fields | Sports tracks, playgrounds, landscaping |

| Environmental Impact | Recycled material, limited lifespan | Often manufactured with better environmental compliance |

| Shock Absorption | Good | Excellent |

| Weather Resistance | Moderate | Superior |

Introduction to SBR and EPDM Granules

SBR granules, derived from Styrene-Butadiene Rubber, offer durability and cost-effectiveness for playgrounds and sports surfaces, while EPDM granules, made from Ethylene Propylene Diene Monomer, provide superior UV resistance, elasticity, and vibrant color options. The molecular structure of EPDM enhances weather resistance and longevity compared to the slightly less resilient SBR. Choosing between SBR and EPDM granules depends on factors like environmental exposure, budget, and desired surface performance.

Composition and Material Properties

SBR granules are made from recycled styrene-butadiene rubber, offering durability and cost-effectiveness with moderate elasticity and abrasion resistance. EPDM granules consist of ethylene propylene diene monomer rubber, providing superior weather, UV, and ozone resistance, along with excellent flexibility and long-term performance. Understanding these material properties helps you choose the right granules for applications requiring specific resilience and environmental durability.

Manufacturing Processes Explained

SBR granules are produced from styrene-butadiene rubber through a polymerization process that involves the polymerization of styrene and butadiene monomers, followed by vulcanization and grinding into granules. EPDM granules originate from ethylene propylene diene monomer rubber, manufactured by copolymerizing ethylene, propylene, and a diene component, then vulcanizing and granulating the material. The key difference lies in their base polymers and polymerization methods, impacting the durability and performance characteristics of the granules used in applications like playground surfacing and athletic tracks.

Key Applications and Uses

SBR granules are widely used in playground surfacing, sports fields, and athletic tracks due to their excellent shock absorption and cost-effectiveness. EPDM granules offer superior UV resistance, durability, and color retention, making them ideal for outdoor sports courts, rooftop surfaces, and landscaping projects. Your choice between SBR and EPDM granules depends on the specific application requirements, including performance, aesthetics, and environmental exposure.

Performance and Durability Comparison

SBR granules offer cost-effective shock absorption and durability ideal for playground surfaces but tend to degrade faster under extreme weather conditions compared to EPDM granules. EPDM granules provide superior color retention, UV resistance, and long-term elasticity, making them more durable and suitable for high-performance sports fields. The enhanced wear resistance of EPDM granules results in extended lifespan and consistent performance in diverse environmental settings.

Safety and Environmental Considerations

SBR granules, derived from recycled tires, may contain trace amounts of heavy metals and volatile organic compounds, raising concerns about potential environmental leachates and human exposure during installation and use. EPDM granules, made from ethylene propylene diene monomer rubber, are recognized for their lower toxicity and improved UV resistance, reducing environmental degradation and minimizing harmful emissions. Both materials require proper handling and disposal protocols to ensure safety compliance and environmental protection in playgrounds and sports surfaces.

Cost Analysis: SBR vs EPDM

SBR granules typically offer a more cost-effective solution compared to EPDM granules, with prices approximately 20-30% lower due to their recycled tire origin. EPDM granules command a premium cost, often twice that of SBR, driven by their superior durability, vibrant color retention, and UV resistance. Budget-sensitive projects commonly favor SBR for affordability, while long-term investments prioritize EPDM for enhanced performance and longevity.

Maintenance and Longevity

SBR granules typically require more frequent maintenance due to their lower UV resistance and faster wear rate compared to EPDM granules, which exhibit superior durability and color retention. EPDM granules maintain their elasticity and surface integrity longer, reducing the need for repairs and replacements over time. Your choice of EPDM granules ensures enhanced longevity and less intensive upkeep, providing a cost-effective solution for long-term performance.

Installation Process and Challenges

SBR granules typically require a more complex installation process due to their irregular shape, which can result in less uniform compaction and increased settling over time. EPDM granules offer a smoother, more consistent texture that simplifies spreading and compaction, leading to a more even surface with fewer voids. You may find EPDM granules easier to handle during installation, reducing labor time and minimizing challenges related to surface consistency.

Choosing the Right Granules for Your Project

SBR granules, derived from recycled rubber tires, offer durability and cost-effectiveness, making them ideal for playground surfaces and sports fields requiring shock absorption. EPDM granules, made from ethylene propylene diene monomer rubber, provide superior color retention, UV resistance, and flexibility, perfect for environments demanding aesthetic appeal and long-term performance. Selecting between SBR and EPDM granules depends on project priorities like budget constraints, exposure conditions, and desired lifespan.

SBR Granules vs EPDM Granules Infographic

libmatt.com

libmatt.com