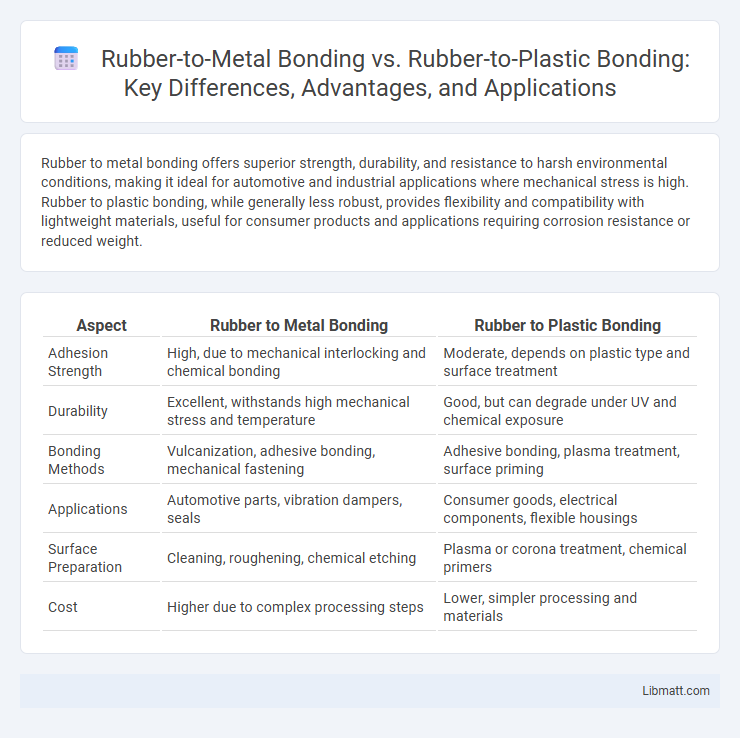

Rubber to metal bonding offers superior strength, durability, and resistance to harsh environmental conditions, making it ideal for automotive and industrial applications where mechanical stress is high. Rubber to plastic bonding, while generally less robust, provides flexibility and compatibility with lightweight materials, useful for consumer products and applications requiring corrosion resistance or reduced weight.

Table of Comparison

| Aspect | Rubber to Metal Bonding | Rubber to Plastic Bonding |

|---|---|---|

| Adhesion Strength | High, due to mechanical interlocking and chemical bonding | Moderate, depends on plastic type and surface treatment |

| Durability | Excellent, withstands high mechanical stress and temperature | Good, but can degrade under UV and chemical exposure |

| Bonding Methods | Vulcanization, adhesive bonding, mechanical fastening | Adhesive bonding, plasma treatment, surface priming |

| Applications | Automotive parts, vibration dampers, seals | Consumer goods, electrical components, flexible housings |

| Surface Preparation | Cleaning, roughening, chemical etching | Plasma or corona treatment, chemical primers |

| Cost | Higher due to complex processing steps | Lower, simpler processing and materials |

Introduction to Rubber to Metal and Rubber to Plastic Bonding

Rubber to metal bonding involves creating a strong adhesive interface between elastomers and metal substrates, essential for applications in automotive, aerospace, and industrial components where durability and resistance to mechanical stress are critical. Rubber to plastic bonding, on the other hand, requires specialized adhesives that can accommodate differences in chemical composition and thermal expansion between elastomers and various plastics, often seen in consumer goods, electronics, and medical devices. Understanding the distinct adhesion mechanisms and surface treatments used in your rubber to metal and rubber to plastic bonding processes ensures optimal performance and longevity in your assembled products.

Key Principles of Rubber Bonding Technologies

Rubber to metal bonding relies on creating a strong chemical adhesive layer combined with mechanical interlocking through surface treatments like etching or priming, ensuring durability under stress and vibration. Rubber to plastic bonding requires compatibility in polymer structures and surface activation methods such as plasma or corona treatment to enhance adhesion strength and flexibility. Understanding these key principles helps optimize your bonding process for enhanced performance and longevity in various applications.

Material Compatibility: Metal vs Plastic Substrates

Rubber to metal bonding offers superior mechanical strength and chemical resistance due to strong adhesion with metal substrates such as steel or aluminum, enhanced by surface treatments like etching or priming. In contrast, rubber to plastic bonding presents challenges related to the diverse chemical composition of plastics like polypropylene or polyethylene, which often require specialized adhesives or surface activation methods such as plasma treatment to improve compatibility. Metal substrates typically provide a more stable and durable base for rubber adhesion compared to plastics, which can vary widely in surface energy and chemical reactivity, influencing bond strength and longevity.

Surface Preparation Techniques for Metal and Plastic

Surface preparation for rubber to metal bonding typically involves abrasive blasting or chemical etching to remove oxides and contaminants, enhancing adhesion by increasing surface roughness and surface energy. In contrast, rubber to plastic bonding requires treatments like plasma, corona discharge, or chemical primers to modify the typically low surface energy of plastics, promoting better compatibility with rubber adhesives. Proper surface activation tailored to the specific metal or plastic substrate is critical to achieving durable and reliable rubber-to-surface bonds.

Adhesive Selection: Metal vs Plastic Bonding Requirements

Adhesive selection for rubber to metal bonding demands high-performance adhesives with excellent resistance to shear stress and temperature variations, typically utilizing epoxy or polyurethane adhesives for durable, strong bonds. Rubber to plastic bonding requires adhesives compatible with the specific plastic type, often involving cyanoacrylates or modified silicones to ensure flexibility and chemical resistance while accommodating varying surface energies. Your choice of adhesive should account for the substrate's mechanical properties and environmental exposure to optimize bond strength and longevity.

Bonding Process Differences: Metal vs Plastic

Rubber to metal bonding involves processes such as adhesive bonding combined with vulcanization, utilizing primers and chemical agents to improve adhesion to metallic surfaces like steel or aluminum. In contrast, rubber to plastic bonding requires surface treatments like corona discharge or plasma treatment to enhance the typically lower surface energy of plastics such as polypropylene or polyethylene. You must select bonding techniques and materials based on the substrate compatibility, curing methods, and environmental resistance for optimal durability and performance.

Performance Characteristics: Strength, Flexibility, and Durability

Rubber to metal bonding offers superior strength and durability due to the strong chemical and mechanical interlocking between rubber and metal surfaces, making it ideal for high-stress applications requiring long-lasting flexibility. In contrast, rubber to plastic bonding generally provides moderate strength and flexibility, as plastic materials often have lower surface energy and varying chemical compatibility, which can reduce bond integrity over time. Your choice depends on the specific performance needs, with rubber to metal bonds excelling in harsh environments requiring robust, durable connections, while rubber to plastic may suit lighter-duty applications with less demanding strength requirements.

Common Applications: Metal-Bonded vs Plastic-Bonded Rubber

Metal-bonded rubber is commonly used in automotive engine mounts, vibration isolators, and industrial machinery where high strength and durability are critical. Plastic-bonded rubber finds applications in consumer goods, medical devices, and lightweight components requiring flexibility and corrosion resistance. The choice depends on load-bearing requirements, environmental exposure, and the mechanical properties of the bonded substrates.

Advantages and Challenges of Each Bonding Method

Rubber to metal bonding offers superior strength, durability, and resistance to wear, making it ideal for high-stress applications such as automotive and industrial components, but challenges include surface preparation complexity and potential corrosion at the interface. Rubber to plastic bonding provides advantages like lightweight assembly, corrosion resistance, and design flexibility, but faces challenges with lower bond strength and difficulties achieving strong adhesion due to plastic surface energy variability. Each bonding method requires tailored adhesives and surface treatments to optimize performance based on the mechanical and environmental demands of the application.

Future Trends in Rubber Bonding Technologies

Future trends in rubber bonding technologies emphasize enhanced durability and environmental sustainability, with innovations in adhesive formulations tailored for rubber to metal and rubber to plastic interfaces. Advanced surface treatments, such as plasma and laser activation, improve bond strength and compatibility across diverse substrates. Integration of smart materials and nanotechnology aims to create adaptive bonds that respond to mechanical stress and temperature changes, revolutionizing industries like automotive and aerospace.

Rubber to metal bonding vs Rubber to plastic bonding Infographic

libmatt.com

libmatt.com