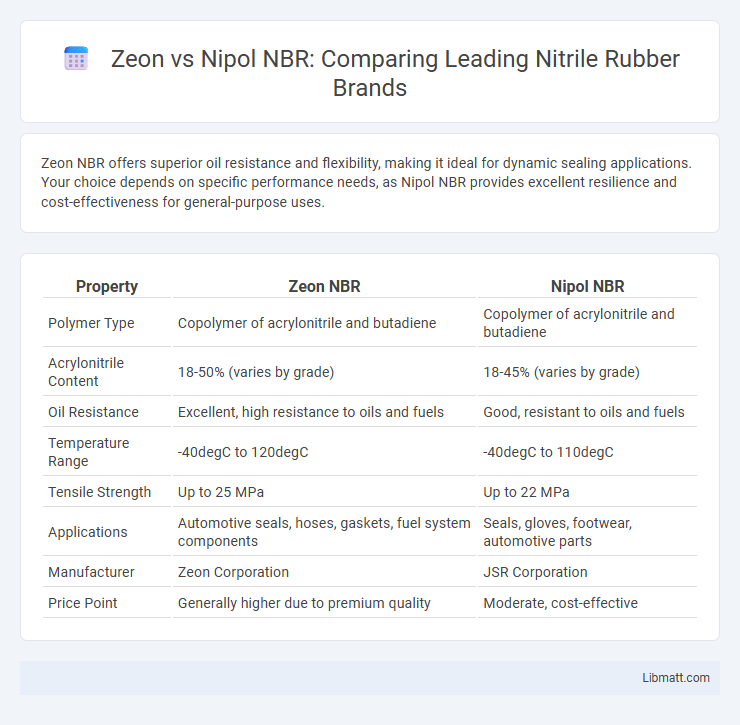

Zeon NBR offers superior oil resistance and flexibility, making it ideal for dynamic sealing applications. Your choice depends on specific performance needs, as Nipol NBR provides excellent resilience and cost-effectiveness for general-purpose uses.

Table of Comparison

| Property | Zeon NBR | Nipol NBR |

|---|---|---|

| Polymer Type | Copolymer of acrylonitrile and butadiene | Copolymer of acrylonitrile and butadiene |

| Acrylonitrile Content | 18-50% (varies by grade) | 18-45% (varies by grade) |

| Oil Resistance | Excellent, high resistance to oils and fuels | Good, resistant to oils and fuels |

| Temperature Range | -40degC to 120degC | -40degC to 110degC |

| Tensile Strength | Up to 25 MPa | Up to 22 MPa |

| Applications | Automotive seals, hoses, gaskets, fuel system components | Seals, gloves, footwear, automotive parts |

| Manufacturer | Zeon Corporation | JSR Corporation |

| Price Point | Generally higher due to premium quality | Moderate, cost-effective |

Introduction to Zeon and Nipol NBR

Zeon NBR and Nipol NBR are leading brands in the synthetic rubber industry, specializing in nitrile butadiene rubber used for applications requiring oil resistance and durability. Zeon produces high-performance NBR polymers tailored for automotive, industrial, and consumer goods, emphasizing advanced chemical properties and consistent quality. Nipol NBR, manufactured by JSR Corporation, offers versatile grades with excellent mechanical strength and flexibility, making it ideal for seals, hoses, and fuel handling components.

Overview of NBR (Acrylonitrile Butadiene Rubber)

NBR (Acrylonitrile Butadiene Rubber) is a synthetic rubber known for its excellent resistance to oils, fuels, and other chemicals, making it ideal for seals, gaskets, and hoses. Zeon and Nipol NBR brands offer high-performance variations with tailored molecular structures that enhance durability and elasticity under harsh conditions. You can expect superior abrasion resistance and improved temperature tolerance, crucial for automotive, industrial, and oilfield applications.

Zeon NBR: Brand Background and Production

Zeon NBR is manufactured by Zeon Corporation, a leading Japanese chemical company specializing in synthetic rubber and specialty chemicals. Established in 1950, Zeon has developed advanced NBR (nitrile butadiene rubber) products known for superior oil resistance, durability, and consistent quality, widely used in automotive seals, hoses, and industrial applications. Their state-of-the-art production facilities leverage proprietary polymerization technologies to ensure enhanced performance characteristics compared to standard NBR offerings.

Nipol NBR: Brand Background and Production

Nipol NBR, produced by Zeon Corporation, is a synthetic rubber brand renowned for its exceptional acrylonitrile-butadiene content, catering to industries demanding superior oil, fuel, and chemical resistance. Zeon's advanced polymerization technology ensures Nipol NBR exhibits consistent quality, excellent tensile strength, and enhanced adhesion properties, making it ideal for automotive and industrial applications. With a robust global manufacturing network, Zeon continuously innovates Nipol NBR grades to meet diverse performance requirements and regulatory standards.

Key Physical Properties Comparison

Zeon NBR exhibits superior tensile strength, typically ranging from 15 to 25 MPa, compared to Nipol NBR's 12 to 20 MPa, enhancing its durability in demanding applications. Shore A hardness values for Zeon NBR span 60 to 90, offering greater flexibility than Nipol's typical 65 to 85 range. Zeon NBR also shows improved compression set resistance, generally below 20%, while Nipol NBR tends to have a higher compression set around 25-30%, affecting long-term sealing performance.

Chemical Resistance: Zeon vs Nipol NBR

Zeon NBR demonstrates superior chemical resistance compared to Nipol NBR, particularly against aromatic hydrocarbons, oils, and fuels. Zeon's unique polymer composition enhances its tolerance to aggressive chemicals, reducing swelling and degradation in harsh environments. Nipol NBR, while effective for general use, exhibits decreased resistance in prolonged exposure to specific solvents and acidic conditions.

Performance in Automotive Applications

Zeon NBR exhibits superior oil and fuel resistance compared to Nipol NBR, making it ideal for automotive fuel systems and seals exposed to harsh hydrocarbon environments. Nipol NBR offers excellent abrasion resistance and flexibility, suitable for dynamic automotive components such as hoses and gaskets. Both materials deliver strong performance in automotive applications, but Zeon's enhanced chemical stability provides longer service life under aggressive conditions.

Cost and Availability Analysis

Zeon NBR typically offers competitive pricing compared to Nipol NBR, making it a cost-effective choice for industrial applications requiring high-performance nitrile rubber. Availability of Zeon NBR is generally strong due to its widespread global manufacturing network, ensuring consistent supply even in high-demand markets. Your choice between Zeon and Nipol NBR will depend on balancing budget constraints with the specific availability in your region for timely procurement.

Environmental Impact and Sustainability

Zeon and Nipol NBR both prioritize sustainability, but Zeon's manufacturing process integrates advanced eco-friendly technologies that reduce carbon emissions and waste generation significantly. Nipol NBR emphasizes the use of renewable raw materials and a closed-loop recycling system to minimize environmental footprint. Zeon's commitment to sustainable development is reflected in its certifications such as ISO 14001, underscoring rigorous environmental management standards.

Choosing Between Zeon and Nipol NBR: Key Considerations

Choosing between Zeon and Nipol NBR hinges on specific performance requirements such as chemical resistance, temperature range, and mechanical properties. Zeon NBR typically offers superior oil and fuel resistance, making it ideal for automotive and industrial applications, while Nipol NBR is favored for its cost-effectiveness and consistent quality in general-purpose sealing solutions. Evaluating your application's environmental conditions and budget constraints will guide your optimal selection.

Zeon vs Nipol NBR Infographic

libmatt.com

libmatt.com