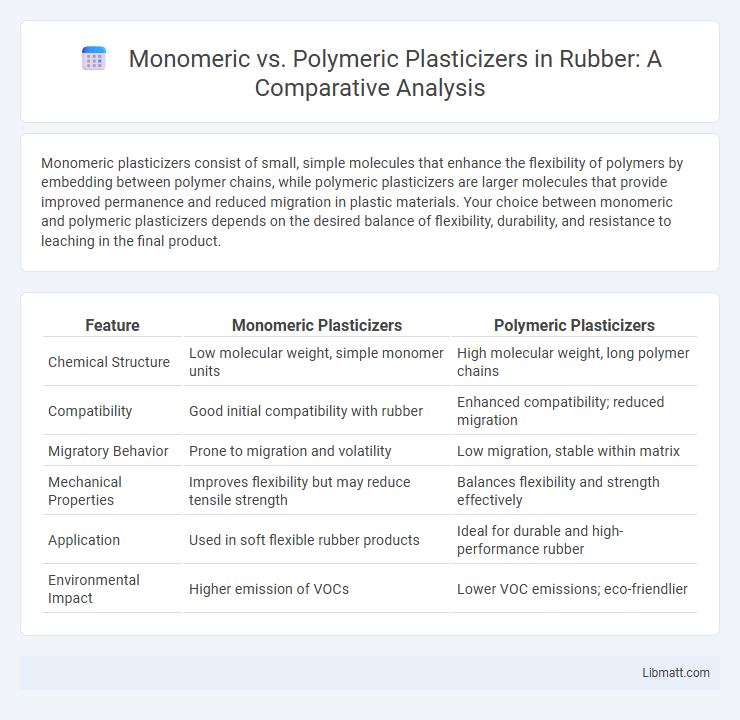

Monomeric plasticizers consist of small, simple molecules that enhance the flexibility of polymers by embedding between polymer chains, while polymeric plasticizers are larger molecules that provide improved permanence and reduced migration in plastic materials. Your choice between monomeric and polymeric plasticizers depends on the desired balance of flexibility, durability, and resistance to leaching in the final product.

Table of Comparison

| Feature | Monomeric Plasticizers | Polymeric Plasticizers |

|---|---|---|

| Chemical Structure | Low molecular weight, simple monomer units | High molecular weight, long polymer chains |

| Compatibility | Good initial compatibility with rubber | Enhanced compatibility; reduced migration |

| Migratory Behavior | Prone to migration and volatility | Low migration, stable within matrix |

| Mechanical Properties | Improves flexibility but may reduce tensile strength | Balances flexibility and strength effectively |

| Application | Used in soft flexible rubber products | Ideal for durable and high-performance rubber |

| Environmental Impact | Higher emission of VOCs | Lower VOC emissions; eco-friendlier |

Introduction to Plasticizers

Plasticizers are additives used to increase the flexibility, workability, and durability of polymers by reducing intermolecular forces and enhancing chain mobility. Monomeric plasticizers consist of small, low-molecular-weight molecules that easily integrate into polymer matrices, providing immediate softening effects. Polymeric plasticizers, with their higher molecular weights and extended chain structures, offer improved permanence and reduced migration, making them suitable for long-term applications in flexible plastics.

What Are Monomeric Plasticizers?

Monomeric plasticizers are low-molecular-weight compounds used to increase the flexibility and workability of polymers by embedding themselves between polymer chains, reducing intermolecular forces. These plasticizers are typically small, simple molecules such as phthalates, adipates, or citrates, known for their efficient compatibility with polyvinyl chloride (PVC) and other plastics. Due to their monomeric structure, they often offer superior initial plasticizing efficiency but may exhibit higher volatility and potential for migration compared to polymeric plasticizers.

Key Properties of Monomeric Plasticizers

Monomeric plasticizers are characterized by low molecular weight and high volatility, which enable them to provide excellent initial flexibility and rapid plasticizing effects in polymer matrices. Their simple molecular structures contribute to efficient dispersion within plastics, enhancing workability and softness. Key properties include good compatibility with a wide range of polymers, fast migration rates, and relatively lower permanence compared to polymeric plasticizers.

Overview of Polymeric Plasticizers

Polymeric plasticizers are high-molecular-weight additives designed to improve the flexibility, durability, and thermal stability of polymers by embedding within their matrix without leaching out easily. These plasticizers provide long-term performance benefits, reduce volatility, and enhance the mechanical properties of materials such as PVC and elastomers. Your choice of polymeric plasticizer can significantly impact the lifespan and environmental resistance of the final product compared to monomeric alternatives.

Key Properties of Polymeric Plasticizers

Polymeric plasticizers exhibit superior compatibility with polymers due to their higher molecular weight, resulting in reduced volatility and migration compared to monomeric plasticizers. Their key properties include enhanced thermal stability, improved mechanical performance, and greater resistance to exudation and leaching, which extend the lifespan of plasticized materials. Your applications benefit from polymeric plasticizers' ability to maintain flexibility and durability under harsh environmental conditions.

Monomeric vs Polymeric Plasticizers: Chemical Structure

Monomeric plasticizers consist of small, low molecular weight molecules that integrate easily into polymer chains, enhancing flexibility by increasing free volume. Polymeric plasticizers feature larger, high molecular weight structures with repeating units that provide superior permanence and reduced volatility in the final product. Understanding the chemical structure of these plasticizers influences your selection for optimizing plastic performance and longevity.

Performance Differences: Monomeric vs Polymeric

Monomeric plasticizers typically offer lower molecular weight, resulting in improved plasticizing efficiency, flexibility, and ease of processing for polymers. Polymeric plasticizers, with their higher molecular weight and larger molecular structure, provide enhanced permanence, reduced volatility, and better compatibility with high-performance plastics. The choice between monomeric and polymeric plasticizers significantly influences mechanical properties, thermal stability, and long-term durability of the polymer products.

Applications and End-Use Industries

Monomeric plasticizers are widely used in applications requiring flexibility and durability in products such as PVC films, wire and cable insulation, and automotive parts. Polymeric plasticizers, with their higher molecular weight, are preferred in end-use industries like construction and adhesives where long-term stability and reduced migration are critical. Your choice between monomeric and polymeric plasticizers depends on the specific performance requirements and regulatory standards of the target application.

Environmental and Health Considerations

Monomeric plasticizers often contain phthalates, which have been linked to endocrine disruption and environmental persistence, raising concerns about their impact on human health and ecosystems. Polymeric plasticizers, composed of larger molecules, tend to exhibit lower volatility and reduced leaching, resulting in decreased toxic exposure and enhanced environmental safety. Choosing polymeric plasticizers for your applications can minimize harmful emissions and improve sustainability without compromising plastic flexibility.

Choosing the Right Plasticizer: Factors to Consider

When choosing the right plasticizer for your project, consider the specific application requirements such as flexibility, compatibility, and environmental impact. Monomeric plasticizers offer low molecular weight for enhanced plasticizing efficiency but may have volatility issues, while polymeric plasticizers provide better permanence and reduced migration due to higher molecular weight. Evaluating factors like chemical resistance, processing temperature, and regulatory compliance will ensure the selected plasticizer meets your material performance and sustainability goals.

Monomeric vs Polymeric plasticizers Infographic

libmatt.com

libmatt.com