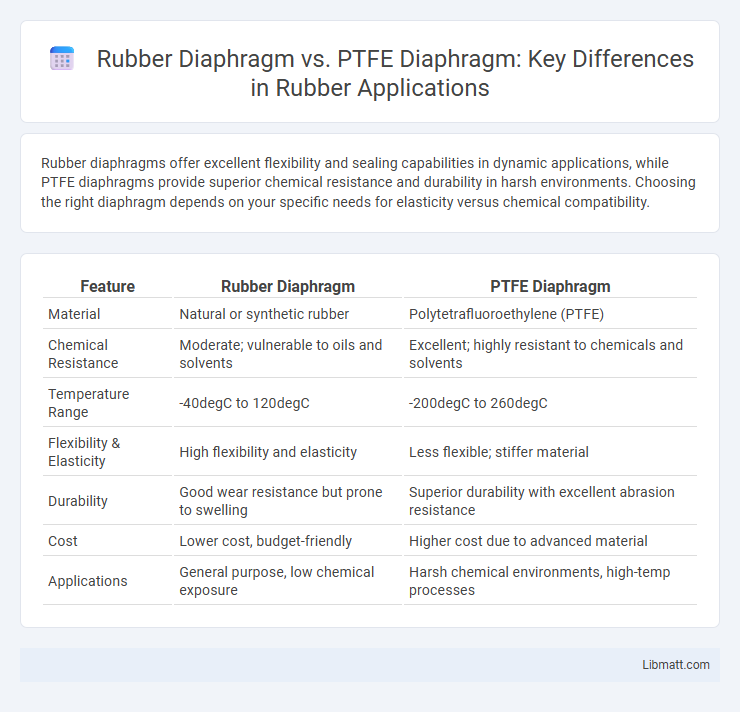

Rubber diaphragms offer excellent flexibility and sealing capabilities in dynamic applications, while PTFE diaphragms provide superior chemical resistance and durability in harsh environments. Choosing the right diaphragm depends on your specific needs for elasticity versus chemical compatibility.

Table of Comparison

| Feature | Rubber Diaphragm | PTFE Diaphragm |

|---|---|---|

| Material | Natural or synthetic rubber | Polytetrafluoroethylene (PTFE) |

| Chemical Resistance | Moderate; vulnerable to oils and solvents | Excellent; highly resistant to chemicals and solvents |

| Temperature Range | -40degC to 120degC | -200degC to 260degC |

| Flexibility & Elasticity | High flexibility and elasticity | Less flexible; stiffer material |

| Durability | Good wear resistance but prone to swelling | Superior durability with excellent abrasion resistance |

| Cost | Lower cost, budget-friendly | Higher cost due to advanced material |

| Applications | General purpose, low chemical exposure | Harsh chemical environments, high-temp processes |

Introduction to Diaphragm Materials

Rubber diaphragms offer excellent flexibility and chemical resistance, making them ideal for applications involving water, oils, and mild chemicals. PTFE diaphragms provide superior chemical inertness and temperature resistance, suited for aggressive media and high-purity environments. Your choice between rubber and PTFE diaphragms should consider factors like chemical compatibility, operating temperature, and mechanical stress.

Overview of Rubber Diaphragms

Rubber diaphragms are flexible membranes commonly used in pumps, valves, and actuators due to their excellent elasticity and chemical resistance. They provide a reliable seal and can absorb pressure fluctuations, making them suitable for a wide range of industrial applications involving water, air, and mild chemicals. Your choice of rubber diaphragm ensures durability and cost-effective performance in systems requiring frequent movement and sealing.

Overview of PTFE Diaphragms

PTFE diaphragms offer superior chemical resistance and high-temperature tolerance compared to rubber diaphragms, making them ideal for aggressive chemical processes and extreme conditions. Their non-stick surface prevents material buildup, ensuring consistent performance and reducing maintenance costs in industrial applications. Choosing PTFE diaphragms enhances your system's durability and reliability in demanding environments where rubber diaphragms may degrade prematurely.

Key Differences Between Rubber and PTFE Diaphragms

Rubber diaphragms offer excellent flexibility and chemical resistance but are limited in high-temperature applications, whereas PTFE diaphragms provide superior chemical inertness and can withstand extreme temperatures. Your choice depends on the specific requirements for durability, chemical compatibility, and temperature tolerance in your application. PTFE diaphragms are ideal for aggressive media and long-lasting performance, while rubber diaphragms excel in cost-effective, flexible sealing solutions.

Chemical Resistance Comparison

Rubber diaphragms offer moderate chemical resistance, performing well against water, oils, and mild acids but deteriorating with exposure to strong solvents, fuels, and aggressive chemicals. PTFE diaphragms demonstrate superior chemical resistance, withstanding a broad range of corrosive substances such as strong acids, alkalis, and solvents without degradation. This makes PTFE diaphragms ideal for applications involving harsh chemical environments where longevity and durability are critical.

Temperature Tolerance Analysis

Rubber diaphragms typically withstand temperatures ranging from -40degC to 120degC depending on the specific compound, such as Nitrile or EPDM, making them suitable for moderate temperature environments. PTFE diaphragms excel in extreme temperature tolerance, withstanding temperatures from -200degC up to 260degC, ideal for high-temperature chemical processing and applications involving aggressive media. The significant difference in temperature tolerance influences the selection of diaphragms based on operational thermal demands and chemical compatibility.

Performance in Industrial Applications

Rubber diaphragms provide excellent flexibility and resilience in industrial applications requiring shock absorption and chemical resistance to non-corrosive substances. PTFE diaphragms offer superior chemical inertness, high-temperature tolerance, and minimal permeability, making them ideal for aggressive chemical processes and sanitary environments. Selecting the right diaphragm depends on your specific industrial conditions, balancing durability, chemical compatibility, and operational temperature.

Longevity and Maintenance Requirements

Rubber diaphragms offer moderate longevity with flexibility that accommodates varying pressure conditions but require frequent maintenance due to susceptibility to wear and chemical degradation. PTFE diaphragms provide superior chemical resistance and extended lifespan, reducing downtime and maintenance frequency, especially in harsh or corrosive environments. Choosing the right diaphragm enhances your system's durability and minimizes operational disruptions.

Cost Considerations: Rubber vs PTFE Diaphragms

Rubber diaphragms generally offer a lower initial cost compared to PTFE diaphragms, making them a budget-friendly choice for many applications. PTFE diaphragms, while more expensive upfront, provide superior chemical resistance, longevity, and reduced maintenance expenses over time. You should weigh the long-term savings from PTFE's durability against the upfront affordability of rubber to determine the most cost-effective option for your specific needs.

Choosing the Right Diaphragm for Your Needs

Rubber diaphragms offer excellent flexibility and cost-effectiveness, making them ideal for applications requiring high elasticity and moderate chemical resistance. PTFE diaphragms provide superior chemical inertness and temperature resistance, suitable for aggressive media and harsh environments. Your selection should consider the operational conditions, chemical compatibility, and durability requirements to ensure optimal diaphragm performance.

Rubber Diaphragm vs PTFE Diaphragm Infographic

libmatt.com

libmatt.com