A vulcanizing press applies high pressure and heat directly to mold rubber into desired shapes, offering precise control over thickness and surface finish. Your choice depends on production volume and material requirements, as autoclaves provide uniform heat and pressure in a sealed chamber ideal for curing composite materials and large rubber parts.

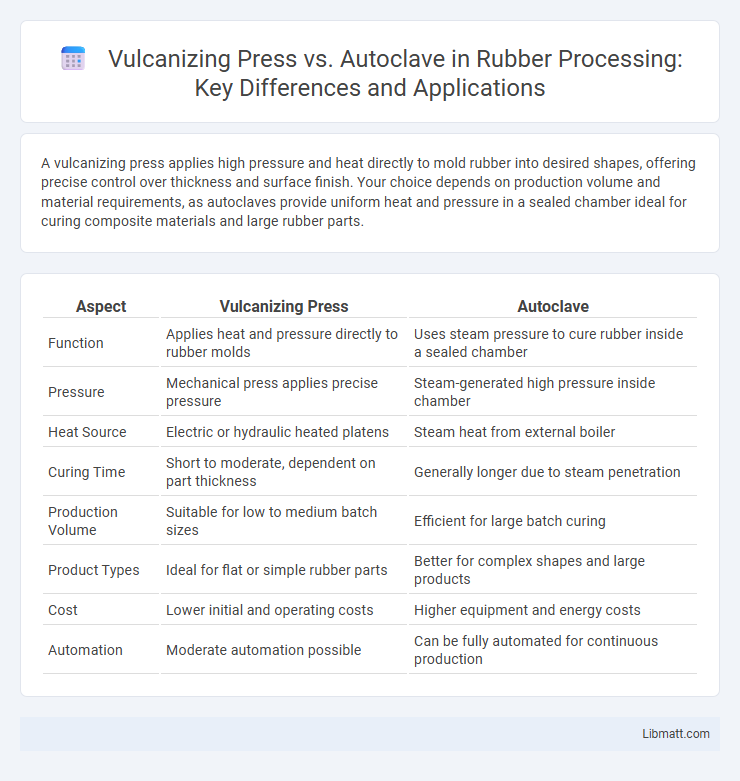

Table of Comparison

| Aspect | Vulcanizing Press | Autoclave |

|---|---|---|

| Function | Applies heat and pressure directly to rubber molds | Uses steam pressure to cure rubber inside a sealed chamber |

| Pressure | Mechanical press applies precise pressure | Steam-generated high pressure inside chamber |

| Heat Source | Electric or hydraulic heated platens | Steam heat from external boiler |

| Curing Time | Short to moderate, dependent on part thickness | Generally longer due to steam penetration |

| Production Volume | Suitable for low to medium batch sizes | Efficient for large batch curing |

| Product Types | Ideal for flat or simple rubber parts | Better for complex shapes and large products |

| Cost | Lower initial and operating costs | Higher equipment and energy costs |

| Automation | Moderate automation possible | Can be fully automated for continuous production |

Introduction to Vulcanization Technologies

Vulcanizing presses and autoclaves represent key vulcanization technologies used in rubber processing, each offering distinct heat and pressure application methods. Vulcanizing presses utilize mechanical pressure through heated platens, enabling precise control for molding and curing rubber products like tires and seals. Autoclaves apply high-pressure steam and heat within sealed chambers, ideal for curing complex, large, or composite rubber components requiring uniform vulcanization.

What is a Vulcanizing Press?

A vulcanizing press is an industrial machine used to apply heat and pressure to rubber materials, facilitating the vulcanization process that enhances elasticity, durability, and heat resistance. It operates by compressing rubber sheets or molds between heated plates, ensuring uniform curing and precise shaping for rubber products like tires, seals, and gaskets. Compared to autoclaves, vulcanizing presses provide faster cycle times and are better suited for producing high-volume, consistent rubber components.

What is an Autoclave in Rubber Processing?

An autoclave in rubber processing is a high-pressure vessel used to cure rubber products through heat and pressure, ensuring uniform vulcanization. It provides precise temperature control, typically between 140degC and 180degC, and pressure up to 15 bar, enhancing rubber's strength and elasticity. Unlike a vulcanizing press that applies pressure via mechanical plates, an autoclave uses steam or hot air to evenly cure complex or large rubber components.

Key Differences Between Vulcanizing Press and Autoclave

Vulcanizing presses apply controlled heat and pressure directly to rubber materials, allowing precise molding and curing in a shorter cycle time. Autoclaves use steam pressure in a sealed chamber to evenly cure composite materials or rubber products, ensuring deep penetration and uniformity over larger batches. The main difference lies in the application method and scale, with vulcanizing presses suited for high-precision, smaller products and autoclaves ideal for bulk processing and complex composite curing.

Advantages of Vulcanizing Press

A vulcanizing press offers precise temperature and pressure control, ensuring consistent and uniform curing of rubber materials. It enables faster cycle times compared to autoclaves, improving production efficiency and reducing labor costs. The compact design of vulcanizing presses allows for easier integration into manufacturing lines, optimizing workspace utilization and maintenance.

Benefits of Using an Autoclave

An autoclave provides precise temperature and pressure control, ensuring superior vulcanization quality and consistency compared to a traditional vulcanizing press. It enhances material strength and durability by evenly curing rubber products, reducing defects and production waste. The controlled environment of an autoclave also supports automation, increasing throughput and enabling complex molding processes.

Applications for Vulcanizing Press Machines

Vulcanizing press machines are primarily used in rubber molding applications, including tire manufacturing, rubber sheet production, and sealing component fabrication. These machines apply heat and pressure to vulcanize rubber, enhancing durability and elasticity in automotive, aerospace, and industrial products. Your choice of a vulcanizing press ensures precise control over the curing process, making it ideal for producing high-quality rubber parts with consistent performance.

Typical Uses for Autoclave Vulcanization

Autoclave vulcanization is typically used for high-quality rubber products requiring precise temperature and pressure control, such as tires, aerospace seals, and medical gloves. This method ensures uniform vulcanization, resulting in enhanced durability and performance of your rubber components. Its ability to accommodate complex shapes and large batch production makes autoclaves ideal for industrial-scale manufacturing.

Factors to Consider When Choosing Between Vulcanizing Press and Autoclave

Choosing between a vulcanizing press and an autoclave depends on factors such as material type, production volume, and required precision. Vulcanizing presses offer fast cycle times and precise control for rubber and composite parts, ideal for smaller batches or intricate designs. Autoclaves provide uniform heat and pressure application, making them better suited for large-scale production and high-performance composites requiring consistent quality.

Conclusion: Which Vulcanization Method is Right for You?

Choosing between a vulcanizing press and an autoclave depends on your specific production needs and material characteristics. A vulcanizing press offers precise control over pressure and temperature, ideal for small to medium batches with complex rubber components, while an autoclave excels in uniform heat distribution for larger-scale, continuous curing processes. Your decision should align with factors like batch size, material type, and desired production speed to optimize efficiency and product quality.

Vulcanizing Press vs Autoclave Infographic

libmatt.com

libmatt.com