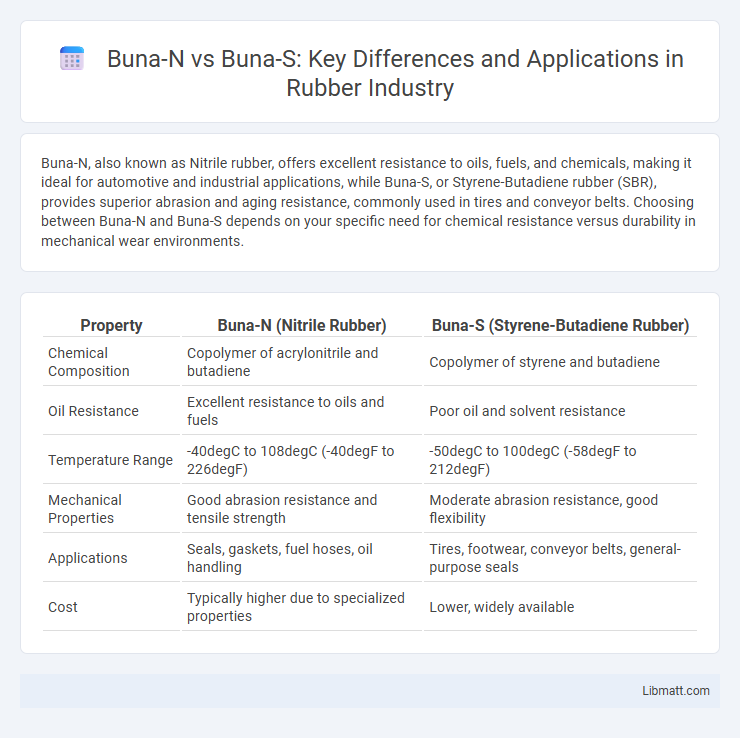

Buna-N, also known as Nitrile rubber, offers excellent resistance to oils, fuels, and chemicals, making it ideal for automotive and industrial applications, while Buna-S, or Styrene-Butadiene rubber (SBR), provides superior abrasion and aging resistance, commonly used in tires and conveyor belts. Choosing between Buna-N and Buna-S depends on your specific need for chemical resistance versus durability in mechanical wear environments.

Table of Comparison

| Property | Buna-N (Nitrile Rubber) | Buna-S (Styrene-Butadiene Rubber) |

|---|---|---|

| Chemical Composition | Copolymer of acrylonitrile and butadiene | Copolymer of styrene and butadiene |

| Oil Resistance | Excellent resistance to oils and fuels | Poor oil and solvent resistance |

| Temperature Range | -40degC to 108degC (-40degF to 226degF) | -50degC to 100degC (-58degF to 212degF) |

| Mechanical Properties | Good abrasion resistance and tensile strength | Moderate abrasion resistance, good flexibility |

| Applications | Seals, gaskets, fuel hoses, oil handling | Tires, footwear, conveyor belts, general-purpose seals |

| Cost | Typically higher due to specialized properties | Lower, widely available |

Introduction to Buna-N and Buna-S

Buna-N, also known as Nitrile rubber, is a synthetic rubber characterized by excellent resistance to oils, fuels, and chemicals, making it ideal for automotive and industrial applications. Buna-S, or Styrene-Butadiene Rubber (SBR), is a synthetic elastomer with strong abrasion resistance and good aging stability, commonly used in tire manufacturing and conveyor belts. Both materials offer diverse mechanical properties but differ significantly in chemical resistance and temperature tolerance.

Chemical Composition and Structure

Buna-N, also known as nitrile rubber, is a copolymer of acrylonitrile and butadiene with a higher acrylonitrile content, providing enhanced resistance to oils and fuels due to its polar nitrile groups. Buna-S, or styrene-butadiene rubber, is a copolymer of styrene and butadiene that features a non-polar structure, resulting in excellent abrasion resistance but lower chemical resistance compared to Buna-N. Understanding the differences in polymer composition and molecular structure helps you select the appropriate material for specific chemical exposure and mechanical performance requirements.

Physical and Mechanical Properties

Buna-N (Nitrile) and Buna-S (SBR) differ significantly in their physical and mechanical properties, with Buna-N offering higher tensile strength and better resistance to oils, fuels, and chemicals, making it ideal for applications requiring durability in harsh environments. Buna-S excels in abrasion resistance and flexibility at low temperatures but exhibits lower resistance to oils and chemicals compared to Buna-N. Your choice between Buna-N and Buna-S should consider these factors to ensure optimal performance in sealing, gaskets, or hose materials.

Resistance to Chemicals and Oils

Buna-N (Nitrile) offers exceptional resistance to oils, fuels, and many chemicals due to its acrylonitrile content, making it ideal for applications involving petroleum-based fluids. Buna-S (Styrene-Butadiene) provides moderate chemical resistance but performs poorly against oils and solvents, limiting its use in environments exposed to hydrocarbons. When selecting a material for sealing or gasket needs, assessing your exposure to oils and chemicals ensures Buna-N is your best choice for durability and longevity.

Temperature Performance Ranges

Buna-N (Nitrile) rubber exhibits a temperature performance range typically from -40degC to 120degC, providing excellent resistance to oils and fuels, making it ideal for automotive and industrial applications. Buna-S (Styrene-Butadiene) rubber performs effectively within a narrower temperature range, generally from -50degC to 70degC, with superior wear resistance but less chemical resistance compared to Buna-N. The extended high-temperature tolerance of Buna-N supports its use in environments requiring sustained exposure to elevated temperatures, whereas Buna-S is better suited for applications demanding exceptional abrasion resistance at lower temperature extremes.

Common Industrial Applications

Buna-N (Nitrile) is widely used in automotive fuel systems, oil handling, and hydraulic applications due to its excellent resistance to petroleum-based oils and fuels. Buna-S (Styrene-Butadiene) is commonly applied in seals, gaskets, and conveyor belts where abrasion resistance and flexibility in low temperatures are essential. Both elastomers serve crucial roles in manufacturing, but Buna-N dominates in environments requiring superior oil and fuel resistance, while Buna-S excels in wear-resistant applications.

Cost and Availability Comparison

Buna-N (Nitrile) offers a more cost-effective solution compared to Buna-S (Chlorosulfonated Polyethylene), making it ideal for budget-conscious applications. Buna-N is widely available due to its established use in various industries, ensuring easier procurement and lower lead times. Your choice depends on balancing cost considerations with specific material performance requirements.

Environmental and Safety Considerations

Buna-N (Nitrile) offers excellent resistance to oils, fuels, and chemicals, making it ideal for environments with exposure to petroleum-based substances, while Buna-S (Styrene-Butadiene) provides good wear resistance but poorer chemical resistance, especially to oils and solvents. In terms of safety, Buna-N's higher resistance to petroleum products reduces the risk of material degradation and failure in industrial applications, enhancing operational safety. Buna-S, though cost-effective, is more prone to oxidative degradation and should be avoided in harsh chemical environments to prevent premature wear and potential hazards.

Durability and Longevity

Buna-N (Nitrile) offers superior durability and longevity in oil and fuel resistance, making it ideal for applications involving petroleum-based fluids. Buna-S (Styrene-Butadiene) provides good wear resistance but degrades faster under exposure to oils and chemicals compared to Buna-N. Selecting Buna-N for your equipment ensures enhanced lifespan and reduced maintenance costs in demanding industrial environments.

Choosing Between Buna-N and Buna-S

Choosing between Buna-N and Buna-S depends on your application's chemical exposure and temperature requirements. Buna-N, or nitrile rubber, excels in resistance to oils, fuels, and temperature ranges from -40degC to 120degC, making it ideal for automotive and industrial sealing. Buna-S, or styrene-butadiene rubber, offers superior abrasion resistance and flexibility in colder conditions but lacks the chemical resistance of Buna-N, making it suitable for applications involving dry environments and moderate chemicals.

Buna-N vs Buna-S Infographic

libmatt.com

libmatt.com