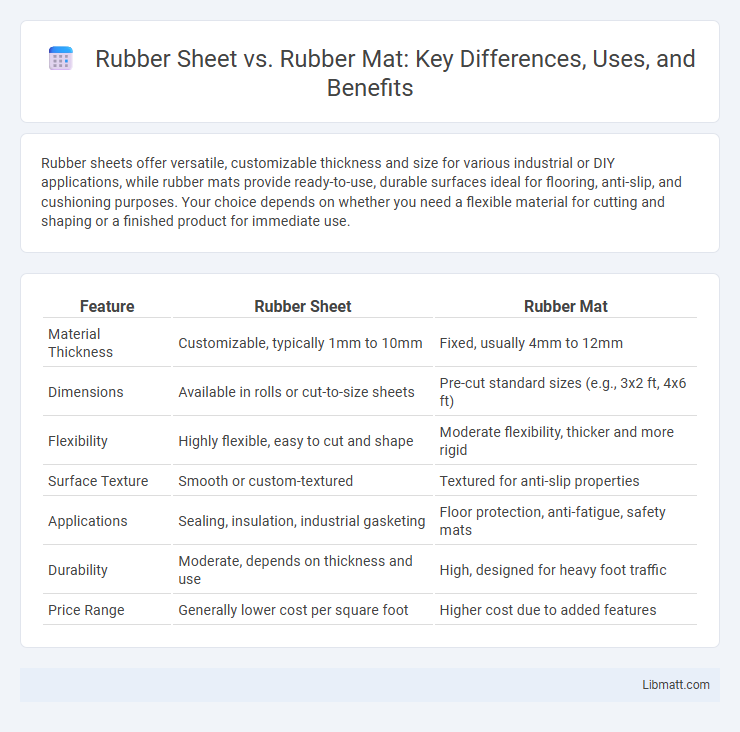

Rubber sheets offer versatile, customizable thickness and size for various industrial or DIY applications, while rubber mats provide ready-to-use, durable surfaces ideal for flooring, anti-slip, and cushioning purposes. Your choice depends on whether you need a flexible material for cutting and shaping or a finished product for immediate use.

Table of Comparison

| Feature | Rubber Sheet | Rubber Mat |

|---|---|---|

| Material Thickness | Customizable, typically 1mm to 10mm | Fixed, usually 4mm to 12mm |

| Dimensions | Available in rolls or cut-to-size sheets | Pre-cut standard sizes (e.g., 3x2 ft, 4x6 ft) |

| Flexibility | Highly flexible, easy to cut and shape | Moderate flexibility, thicker and more rigid |

| Surface Texture | Smooth or custom-textured | Textured for anti-slip properties |

| Applications | Sealing, insulation, industrial gasketing | Floor protection, anti-fatigue, safety mats |

| Durability | Moderate, depends on thickness and use | High, designed for heavy foot traffic |

| Price Range | Generally lower cost per square foot | Higher cost due to added features |

Introduction to Rubber Sheet vs Rubber Mat

Rubber sheets and rubber mats are versatile industrial materials designed for different applications, with rubber sheets typically used for cutting, sealing, and insulation purposes due to their customizable thickness and size. Rubber mats are often pre-sized and textured, providing anti-slip surfaces for safety in workplaces, gyms, and entryways. The primary difference lies in their form factor and intended use, influencing factors such as durability, flexibility, and installation methods.

Key Differences Between Rubber Sheets and Rubber Mats

Rubber sheets are thin, flexible rolls or slabs primarily used for custom fabrication, insulation, and sealing, while rubber mats are thicker, pre-cut, and designed for impact absorption and anti-slip applications. Rubber sheets provide versatility in thickness and size options, making them suitable for industrial and manufacturing purposes, whereas rubber mats offer ready-to-use solutions for flooring, gym, and workspace safety. The durability and texture of rubber mats are optimized for heavy foot traffic, contrasting with the adaptable and easily processed nature of rubber sheets.

Material Composition and Durability

Rubber sheets are typically made from synthetic or natural rubber compounds that provide elasticity and resistance to wear, making them ideal for sealing and insulation purposes. Rubber mats often feature reinforced materials such as fabric backing or multi-layer construction, enhancing their durability against heavy foot traffic and impact. Choosing the right product depends on your specific application, as rubber mats generally offer superior toughness for flooring, while rubber sheets excel in flexibility and chemical resistance.

Common Applications of Rubber Sheets

Rubber sheets are widely used in industrial sealing, gaskets, and vibration dampening due to their customizable thickness and durability. They provide excellent chemical resistance and flexibility, making them ideal for automotive, manufacturing, and construction industries. Their versatility allows for precise cutting to fit specific equipment and machinery components, enhancing protection and performance.

Popular Uses for Rubber Mats

Rubber mats are widely used in gyms, workshops, and industrial settings due to their durability, slip resistance, and cushioning properties, providing safety and comfort in high-traffic areas. Unlike rubber sheets, mats often come with textured surfaces that enhance grip and prevent accidents, making them ideal for wet or oily environments. Understanding these popular uses can help you select the appropriate rubber product for your specific flooring needs.

Safety and Anti-Slip Features

Rubber sheets provide a uniform, durable surface with excellent grip, making them ideal for custom-cut applications where safety and anti-slip properties are critical. Rubber mats often come with textured or patterned surfaces specifically designed to enhance traction and reduce the risk of slips in high-traffic areas or wet conditions. Evaluating your environment and usage needs helps determine whether the versatile rubber sheet or the ready-to-use rubber mat best improves your safety measures.

Installation and Maintenance Comparison

Rubber sheets offer a seamless installation process, allowing for custom cuts that fit any space perfectly, while rubber mats provide easy portability and quick placement without permanent fixing. Maintenance for rubber sheets involves regular cleaning and occasional surface inspections to prevent wear, whereas rubber mats can be removed and cleaned individually, making them more convenient for spot maintenance. Your choice between the two depends on whether you prioritize a durable, integrated solution or flexible, easy-to-maintain flooring options.

Cost Considerations: Sheets vs Mats

Rubber sheets generally offer a lower cost per square foot compared to rubber mats, making them more economical for large-scale projects or custom cutting. Rubber mats, however, provide convenience with pre-cut sizes and enhanced durability features that might justify a higher upfront investment. Evaluating your specific application and budget will help determine if the cost savings of rubber sheets outweigh the ready-to-use benefits of rubber mats.

Environmental Impact and Sustainability

Rubber sheets typically have a lower environmental impact when made from natural rubber, as they are biodegradable and sourced from renewable latex, whereas rubber mats often contain synthetic materials derived from petroleum, contributing to higher carbon emissions and landfill waste. Recycling programs for rubber sheets are more established, improving their sustainability profile compared to many rubber mats that combine rubber with other materials, complicating recycling efforts. Opting for certified eco-friendly rubber sheets supports sustainable forestry and reduces deforestation risks associated with synthetic alternatives.

Which is Best for Your Needs?

Rubber sheets offer versatility with customizable thickness and size, ideal for industrial sealing, insulation, and heavy-duty applications, while rubber mats provide durable, cushioned surface protection suitable for flooring, anti-fatigue support, and slip resistance. Your choice depends on the specific function--choose rubber sheets for tailored protection and insulation or rubber mats for comfort and safety in high-traffic areas. Understanding these differences ensures you select the best rubber product to maximize performance and longevity in your intended use.

Rubber Sheet vs Rubber Mat Infographic

libmatt.com

libmatt.com