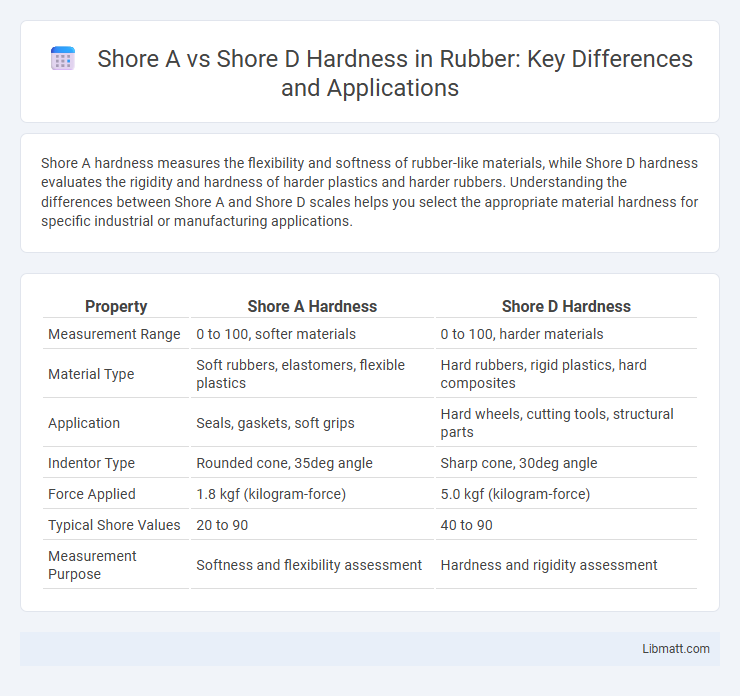

Shore A hardness measures the flexibility and softness of rubber-like materials, while Shore D hardness evaluates the rigidity and hardness of harder plastics and harder rubbers. Understanding the differences between Shore A and Shore D scales helps you select the appropriate material hardness for specific industrial or manufacturing applications.

Table of Comparison

| Property | Shore A Hardness | Shore D Hardness |

|---|---|---|

| Measurement Range | 0 to 100, softer materials | 0 to 100, harder materials |

| Material Type | Soft rubbers, elastomers, flexible plastics | Hard rubbers, rigid plastics, hard composites |

| Application | Seals, gaskets, soft grips | Hard wheels, cutting tools, structural parts |

| Indentor Type | Rounded cone, 35deg angle | Sharp cone, 30deg angle |

| Force Applied | 1.8 kgf (kilogram-force) | 5.0 kgf (kilogram-force) |

| Typical Shore Values | 20 to 90 | 40 to 90 |

| Measurement Purpose | Softness and flexibility assessment | Hardness and rigidity assessment |

Introduction to Shore Hardness Scales

Shore hardness scales measure the resistance of materials to indentation, with Shore A and Shore D commonly used for polymers and rubbers. Shore A scale evaluates softer, flexible materials like elastomers, while Shore D assesses harder plastics and rigid polymers. Understanding the difference helps you select the right material hardness for your specific application requirements.

Understanding Shore A Hardness

Shore A hardness measures the resistance of softer materials like rubber, elastomers, and flexible plastics to indentation, typically used for items like rubber tires or gaskets. Shore D hardness is designed for harder materials such as hard plastics and resins, providing a scale for materials that require greater rigidity. Understanding Shore A hardness helps you accurately select materials based on flexibility and durability for applications requiring softer, more elastic properties.

Overview of Shore D Hardness

Shore D hardness measures the hardness of rigid materials such as hard plastics and hard rubbers, using a durometer with a sharper indenter and higher spring force compared to Shore A. It is ideal for testing materials with hardness values typically ranging from 50 to 90 Shore D, providing a scale for evaluating stiffness and resistance to indentation. The Shore D scale is essential in industries requiring precise hardness measurements for durable, engineering-grade polymers and composites.

Key Differences Between Shore A and Shore D

Shore A and Shore D hardness scales measure the resistance of materials to indentation, with Shore A designed for softer, flexible materials like rubber and elastomers, and Shore D targeting harder materials such as hard plastics and rigid polymers. The Shore A scale ranges from 0 to 100, indicating softer materials, while Shore D also ranges 0 to 100 but for significantly harder substances. Understanding these key differences helps you select the appropriate hardness measurement for accurate material performance assessment in various industrial applications.

Materials Commonly Tested With Shore A

Shore A hardness is commonly used to test softer materials such as rubber, elastomers, and flexible plastics, which require precise measurement of their pliability and resistance to indentation. This scale is ideal for materials like silicone, nitrile, neoprene, and polyurethane, which are often used in applications including seals, gaskets, and flexible hoses. You can rely on Shore A testing to accurately assess the durability and flexibility of materials critical to product performance in automotive, medical, and consumer goods industries.

Applications Suited for Shore D Hardness

Shore D hardness is ideal for applications requiring high durability and resistance to impact, such as automotive components, industrial tools, and construction materials. This scale measures harder materials like hard plastics, rigid polymers, and tough elastomers, making it suitable for products subjected to heavy wear and mechanical stress. Your choice of Shore D hardness ensures optimal performance in demanding environments where rigidity and strength are essential.

How to Choose Between Shore A and Shore D

Choosing between Shore A and Shore D hardness depends on the material's flexibility and application requirements. Shore A is ideal for softer, more flexible materials like rubber and elastomers, while Shore D suits harder, rigid plastics and resins. Understanding your material's durability and deformation needs ensures you select the appropriate Shore hardness for accurate performance testing.

Testing Procedures for Shore A vs Shore D

Shore A and Shore D hardness tests use durometers tailored for different material types, with Shore A designed for softer materials like rubber and elastomers, while Shore D targets harder plastics and harder rubbers. The testing procedure involves pressing the durometer's indenter into the material surface, where Shore A uses a blunt indenter to measure depth of indentation, and Shore D employs a sharper, pointed indenter for firmer surfaces. Accurate Shore hardness testing requires consistent pressure, stable test conditions, and proper calibration to ensure reliable measurements for quality control in material selection.

Interpreting Shore A and Shore D Results

Shore A hardness measures the softness of flexible materials such as rubber and elastomers, while Shore D hardness evaluates harder materials like hard plastics and rigid polymers. When interpreting your Shore A and Shore D results, higher values indicate increased material hardness, but comparisons should only be made within the same scale due to their different measurement ranges and applications. Understanding these scales ensures accurate material selection for your specific durability and flexibility requirements.

Conclusion: Selecting the Right Hardness Scale

Selecting the right hardness scale depends on the material type and application requirements, with Shore A suited for softer, flexible materials like rubber and elastomers, while Shore D targets harder plastics and rigid polymers. Accurate hardness measurement ensures optimal performance, durability, and resistance to wear in industrial or product design contexts. Understanding the distinct scales facilitates better material selection and quality control in manufacturing processes.

Shore A vs Shore D hardness Infographic

libmatt.com

libmatt.com