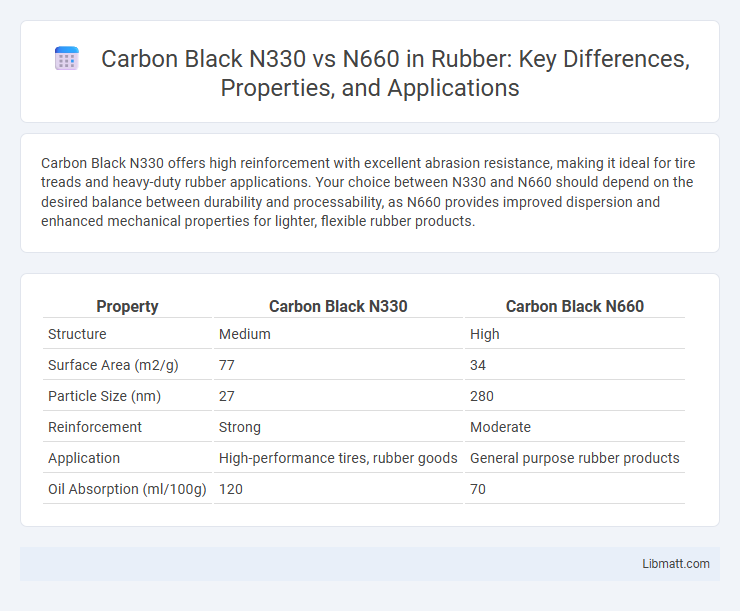

Carbon Black N330 offers high reinforcement with excellent abrasion resistance, making it ideal for tire treads and heavy-duty rubber applications. Your choice between N330 and N660 should depend on the desired balance between durability and processability, as N660 provides improved dispersion and enhanced mechanical properties for lighter, flexible rubber products.

Table of Comparison

| Property | Carbon Black N330 | Carbon Black N660 |

|---|---|---|

| Structure | Medium | High |

| Surface Area (m2/g) | 77 | 34 |

| Particle Size (nm) | 27 | 280 |

| Reinforcement | Strong | Moderate |

| Application | High-performance tires, rubber goods | General purpose rubber products |

| Oil Absorption (ml/100g) | 120 | 70 |

Introduction: Understanding Carbon Black N330 and N660

Carbon Black N330 and N660 are essential grades used in rubber reinforcement, each offering distinct particle sizes and surface areas that affect tire performance and durability. N330 features smaller particles and higher surface area, providing enhanced tensile strength and abrasion resistance, ideal for heavy-duty tire applications. Your choice between N330 and N660 impacts product longevity and performance based on specific industrial requirements.

Chemical Composition and Structure Comparison

Carbon Black N330 exhibits a higher surface area and finer particle size compared to N660, resulting in enhanced reinforcement properties in rubber compounds. Chemically, both N330 and N660 consist primarily of elemental carbon with minimal impurities, but N330's higher structure leads to greater complex aggregate formations. Your choice between N330 and N660 should consider these differences to optimize the chemical interaction and structural integration within your specific application.

Manufacturing Processes: N330 vs N660

Carbon Black N330 is produced through the furnace black process, yielding a medium surface area and structure ideal for reinforcing rubber in tire treads and general rubber products. N660 is manufactured via the channel black process, which creates a lower surface area and structure suited for applications requiring higher resistance to abrasion and processing stability. The differing manufacturing techniques directly impact the physical properties, making N330 more versatile for dynamic applications and N660 preferable for static rubber goods.

Particle Size and Surface Area Differences

Carbon Black N330 features a smaller particle size of approximately 27 nm, resulting in a higher surface area of about 77 m2/g, which enhances reinforcement and abrasion resistance in rubber compounds. In contrast, Carbon Black N660 has a larger particle size near 52 nm, providing a lower surface area around 39 m2/g, making it suitable for applications requiring lower hysteresis and improved dispersion. The particle size and surface area differences between N330 and N660 directly influence the mechanical properties and processing behavior of reinforced polymers.

Physical Properties and Performance Metrics

Carbon Black N330 has a higher structure and surface area compared to N660, resulting in better reinforcement properties and enhanced tensile strength for rubber compounds. N660 exhibits lower abrasion resistance but provides improved processing ease and dispersibility, making it suitable for applications requiring smoother rubber surfaces. Your choice between N330 and N660 should consider the trade-off between mechanical strength and processing efficiency based on specific application requirements.

Application Suitability: N330 vs N660

Carbon Black N330 excels in applications requiring high reinforcement and improved abrasion resistance, making it ideal for tire treads and heavy-duty rubber products. In contrast, N660 is better suited for less demanding applications such as inner liners and sidewalls, where good processing and moderate reinforcement are sufficient. Your choice between N330 and N660 should consider the specific performance needs and durability requirements of the final product.

Impact on Rubber Reinforcement and Durability

Carbon Black N330 offers higher reinforcement and superior abrasion resistance compared to N660, resulting in enhanced rubber durability and improved tensile strength for demanding applications. N660 provides moderate reinforcement with greater softness, contributing to better flexibility but slightly lower wear resistance. Your choice between N330 and N660 will significantly affect the balance between rubber toughness and elasticity, optimizing performance based on specific end-use requirements.

Processing Behavior in Industrial Settings

Carbon Black N330 exhibits superior dispersion and consistent viscosity, making it ideal for high-speed mixing and extrusion processes in industrial applications. In comparison, N660 offers better flow properties but may require adjustments in processing parameters to maintain uniform compound quality. Both grades influence the mechanical performance and conductivity of the final product, with N330 favored for applications demanding high reinforcement and N660 preferred for improved processability.

Cost Analysis and Economic Considerations

Carbon Black N330 generally presents a lower cost per unit compared to N660, making it a preferred choice for manufacturers aiming to optimize production budgets. The higher reinforcing properties of N330 often translate to improved tire durability and performance, potentially reducing long-term replacement expenses despite its upfront cost. N660, while more expensive, offers advantages in processability and finish, which can justify its use in premium products where aesthetic quality and specific performance traits influence economic returns.

Environmental Footprint and Sustainability Factors

Carbon Black N330 exhibits a lower environmental footprint compared to N660 due to its higher reinforcement efficiency, requiring less material for equivalent performance in tire manufacturing. N330's production generates fewer greenhouse gas emissions and consumes less energy, contributing to improved sustainability metrics. The enhanced durability and fuel efficiency of products using N330 further reduce lifecycle environmental impacts relative to those utilizing N660.

Carbon Black N330 vs N660 Infographic

libmatt.com

libmatt.com