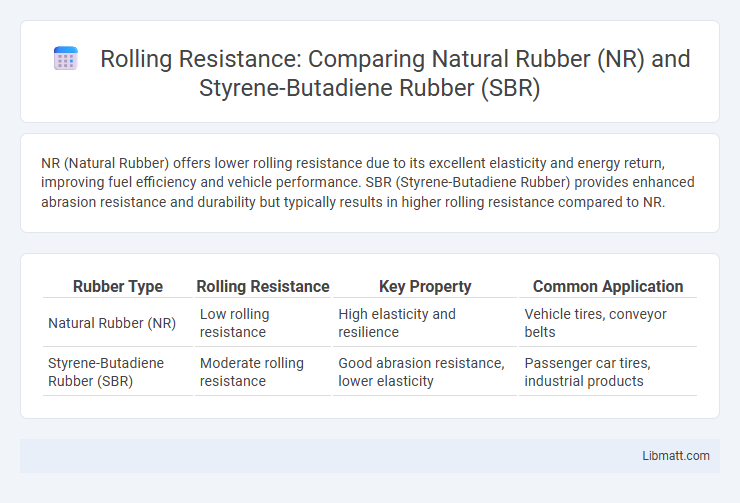

NR (Natural Rubber) offers lower rolling resistance due to its excellent elasticity and energy return, improving fuel efficiency and vehicle performance. SBR (Styrene-Butadiene Rubber) provides enhanced abrasion resistance and durability but typically results in higher rolling resistance compared to NR.

Table of Comparison

| Rubber Type | Rolling Resistance | Key Property | Common Application |

|---|---|---|---|

| Natural Rubber (NR) | Low rolling resistance | High elasticity and resilience | Vehicle tires, conveyor belts |

| Styrene-Butadiene Rubber (SBR) | Moderate rolling resistance | Good abrasion resistance, lower elasticity | Passenger car tires, industrial products |

Introduction to Rolling Resistance

Rolling resistance is the energy loss experienced when a tire rolls on a surface, primarily influenced by the tire's material composition and deformation properties. Natural rubber (NR) exhibits lower rolling resistance due to its superior elasticity and resilience compared to styrene-butadiene rubber (SBR), which tends to have higher hysteresis losses. Optimizing rolling resistance through NR usage enhances fuel efficiency and reduces CO2 emissions in automotive applications.

Importance of Rolling Resistance in Tire Performance

Rolling resistance significantly impacts tire performance by influencing fuel efficiency and vehicle handling. NR (Natural Rubber) typically offers lower rolling resistance compared to SBR (Styrene-Butadiene Rubber), enhancing energy savings and reducing emissions. Selecting NR-based compounds in tire manufacturing improves durability and traction, emphasizing its importance in optimizing overall tire efficiency.

Overview of Natural Rubber (NR) and Styrene-Butadiene Rubber (SBR)

Natural Rubber (NR) offers lower rolling resistance due to its superior elasticity and energy return, making it ideal for applications requiring efficiency and durability. Styrene-Butadiene Rubber (SBR) provides enhanced abrasion resistance and aging stability, often used in environments demanding higher wear resistance. Your choice between NR and SBR significantly influences tire performance, balancing fuel efficiency against tread life and durability.

Chemical Structure: NR vs SBR

Natural Rubber (NR) possesses a cis-1,4-polyisoprene structure with high elasticity and low hysteresis, resulting in excellent rolling resistance performance. Styrene-Butadiene Rubber (SBR) is a copolymer of styrene and butadiene with a more irregular, amorphous structure that generally leads to higher rolling resistance compared to NR. Your choice between NR and SBR significantly impacts tire efficiency due to these intrinsic chemical structure differences affecting energy loss during deformation.

Influence of NR on Rolling Resistance

Natural rubber (NR) significantly reduces rolling resistance due to its superior elasticity and low hysteresis loss compared to styrene-butadiene rubber (SBR). The intrinsic molecular structure of NR allows for better energy return during tire deformation, enhancing fuel efficiency and performance. Consequently, incorporating NR in tire compounds optimizes rolling resistance, contributing to lower CO2 emissions and extended tire life.

Influence of SBR on Rolling Resistance

Styrene-butadiene rubber (SBR) significantly reduces rolling resistance due to its enhanced elasticity and energy dissipation properties compared to natural rubber (NR). SBR's molecular structure offers better abrasion resistance and low heat build-up, directly lowering the tire's rolling resistance and improving fuel efficiency. Incorporating SBR in tire compounds leads to optimized rolling resistance performance without compromising durability.

Comparative Analysis: Rolling Resistance of NR vs SBR

Natural rubber (NR) exhibits lower rolling resistance compared to styrene-butadiene rubber (SBR) due to its superior elasticity and resilience, which reduces energy loss during deformation. SBR, while offering better abrasion resistance and aging properties, typically generates higher rolling resistance because of its molecular structure and stiffness. This difference significantly impacts fuel efficiency in automotive tires, with NR-based compounds contributing to improved mileage and reduced carbon emissions.

Impact of Rolling Resistance on Fuel Efficiency

Rolling resistance of tires made with NR (Natural Rubber) is generally lower than that of SBR (Styrene-Butadiene Rubber), directly influencing fuel efficiency by reducing energy loss during motion. Tires incorporating NR exhibit better deformation recovery and elasticity, leading to less heat generation and improved rolling efficiency. Lower rolling resistance in NR-based tires results in decreased fuel consumption and reduced CO2 emissions compared to SBR-based alternatives.

Application Considerations for NR and SBR Compounds

Natural Rubber (NR) compounds exhibit lower rolling resistance, making them ideal for tire applications where fuel efficiency and reduced energy loss are critical. Styrene-Butadiene Rubber (SBR) compounds offer superior abrasion resistance and aging stability, suitable for tires in diverse weather conditions and heavy-duty uses. Your choice between NR and SBR should consider the balance between rolling resistance performance and durability requirements in specific driving environments.

Future Trends in Low Rolling Resistance Tire Materials

Future trends in low rolling resistance tire materials emphasize the increasing use of solution styrene-butadiene rubber (SBR) blended with natural rubber (NR) to optimize performance and sustainability. Innovations in polymer chemistry aim to reduce hysteresis, leading to lower energy loss and enhanced fuel efficiency across driving conditions. Advanced nano-fillers and silica dispersion techniques further improve rolling resistance characteristics, positioning NR-SBR composites as a key material solution for next-generation eco-friendly tires.

Rolling resistance: NR vs SBR Infographic

libmatt.com

libmatt.com