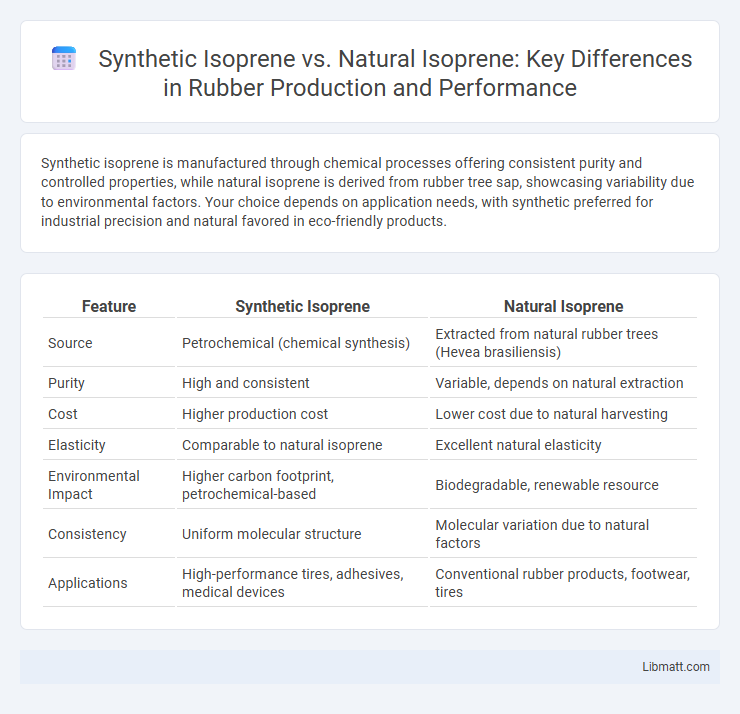

Synthetic isoprene is manufactured through chemical processes offering consistent purity and controlled properties, while natural isoprene is derived from rubber tree sap, showcasing variability due to environmental factors. Your choice depends on application needs, with synthetic preferred for industrial precision and natural favored in eco-friendly products.

Table of Comparison

| Feature | Synthetic Isoprene | Natural Isoprene |

|---|---|---|

| Source | Petrochemical (chemical synthesis) | Extracted from natural rubber trees (Hevea brasiliensis) |

| Purity | High and consistent | Variable, depends on natural extraction |

| Cost | Higher production cost | Lower cost due to natural harvesting |

| Elasticity | Comparable to natural isoprene | Excellent natural elasticity |

| Environmental Impact | Higher carbon footprint, petrochemical-based | Biodegradable, renewable resource |

| Consistency | Uniform molecular structure | Molecular variation due to natural factors |

| Applications | High-performance tires, adhesives, medical devices | Conventional rubber products, footwear, tires |

Introduction to Isoprene: Definition and Importance

Isoprene is a key hydrocarbon building block used in the production of synthetic and natural rubber, essential for manufacturing tires, adhesives, and medical devices. Synthetic isoprene is typically produced through chemical processes such as polymerization of petrochemical feedstocks, offering consistent quality and scalability. Understanding the differences between synthetic and natural isoprene helps optimize your choice of material for specific industrial applications requiring elasticity and durability.

Sources of Isoprene: Natural vs Synthetic Origins

Natural isoprene is primarily derived from plant emissions, especially from species like oaks, eucalyptus, and rubber trees, contributing significantly to atmospheric chemistry and biogenic volatile organic compounds (BVOCs). Synthetic isoprene is industrially produced via catalytic processes, typically through the thermal cracking of naphtha or by isoprene synthesis from petrochemical feedstocks, providing a controlled and consistent supply for manufacturing synthetic rubber and other polymers. The key difference lies in natural isoprene being a renewable, biologically produced hydrocarbon, while synthetic isoprene is a man-made product sourced from fossil fuels.

Chemical Structure and Properties of Isoprene

Synthetic isoprene and natural isoprene share the identical chemical formula C5H8, consisting of a conjugated diene with two double bonds separated by a single carbon-carbon bond, which imparts high reactivity and flexibility in polymerization processes. Natural isoprene is typically derived from biological sources such as rubber trees (Hevea brasiliensis), exhibiting slight variations in impurity profiles and isotopic composition compared to its synthetic counterpart produced via petrochemical routes like catalytic dimerization of piperylene. The physical properties, including boiling point (~34 degC), vapor pressure, and refractive index, remain largely consistent between synthetic and natural isoprene, while minor differences in purity can influence polymerization kinetics and the mechanical properties of resulting isoprene-based elastomers.

Production Methods: Natural Extraction vs Synthetic Synthesis

Natural isoprene is primarily obtained through the extraction from rubber tree latex or other plant sources, involving mechanical tapping and distillation processes, while synthetic isoprene is produced via chemical synthesis methods such as catalytic polymerization of petrochemical feedstocks like n-butene or isobutylene. The production of synthetic isoprene allows for greater control over purity and consistency, making it ideal for industrial applications requiring specific performance characteristics. Understanding these production methods helps you make informed choices about material sourcing based on environmental impact, cost, and product requirements.

Environmental Impact: Comparing Footprints

Synthetic isoprene production relies heavily on petrochemical processes, resulting in higher carbon emissions and non-renewable resource consumption compared to natural isoprene, which is biosynthesized by rubber trees and other plants, offering a renewable and biodegradable alternative. Natural isoprene's carbon footprint is significantly lower due to its biological origin and the potential for carbon sequestration in growing vegetation. Life cycle assessments consistently show that natural isoprene reduces greenhouse gas emissions and environmental pollutants relative to synthetic counterparts, making it a more sustainable choice for eco-conscious applications.

Industrial Applications of Natural and Synthetic Isoprene

Natural isoprene, primarily harvested from rubber trees, serves as a key raw material in producing natural rubber used in automotive tires, adhesives, and medical devices. Synthetic isoprene, derived from petrochemical processes, offers consistent quality and is widely utilized in manufacturing synthetic rubber products such as footwear, hoses, and sealing compounds. Your choice between natural and synthetic isoprene impacts product performance, cost-efficiency, and environmental considerations in various industrial applications.

Cost Analysis: Economic Factors in Isoprene Production

Synthetic isoprene production often incurs higher upfront costs due to advanced chemical synthesis processes and energy consumption, while natural isoprene is typically sourced from renewable biomass with variable availability affecting price stability. Your choice between synthetic and natural isoprene depends on balancing long-term economic factors such as raw material costs, production scale, and market demand. Evaluating operational expenses and sustainability incentives can influence the overall cost-effectiveness of each isoprene type in industrial applications.

Quality and Performance Differences

Synthetic isoprene offers consistent quality with controlled purity and uniform molecular weight, ensuring reliable performance in applications like synthetic rubber manufacturing. Natural isoprene, extracted from rubber trees, may exhibit variability due to environmental factors affecting its purity and physical properties. Your choice between synthetic and natural isoprene impacts product durability, elasticity, and resistance to aging, making synthetic options preferable for high-performance or specialized uses.

Sustainability and Future Trends in Isoprene Utilization

Synthetic isoprene production heavily relies on petroleum-based feedstocks, posing sustainability challenges due to finite resources and carbon emissions, whereas natural isoprene, derived from plant sources, offers a renewable alternative with a lower environmental footprint. Innovations in bioengineering and microbial synthesis are driving future trends toward sustainable isoprene production, enabling scalable and eco-friendly manufacturing processes that reduce dependency on fossil fuels. Your choice between synthetic and natural isoprene will increasingly hinge on sustainability goals and the evolving market demand for greener materials in industries like rubber manufacturing and adhesives.

Conclusion: Choosing Between Synthetic and Natural Isoprene

Synthetic isoprene offers consistent quality and cost-effectiveness ideal for industrial applications, while natural isoprene provides eco-friendly benefits and superior elasticity favored in specialty products. Your choice depends on prioritizing sustainability or performance requirements in manufacturing processes. Balancing environmental impact with product functionality guides the decision between synthetic and natural isoprene.

Synthetic Isoprene vs Natural Isoprene Infographic

libmatt.com

libmatt.com