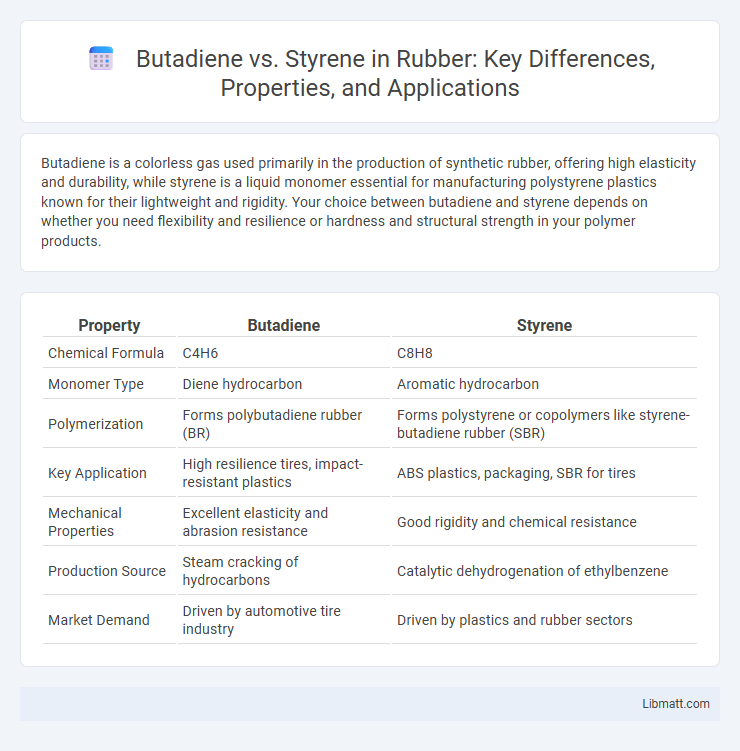

Butadiene is a colorless gas used primarily in the production of synthetic rubber, offering high elasticity and durability, while styrene is a liquid monomer essential for manufacturing polystyrene plastics known for their lightweight and rigidity. Your choice between butadiene and styrene depends on whether you need flexibility and resilience or hardness and structural strength in your polymer products.

Table of Comparison

| Property | Butadiene | Styrene |

|---|---|---|

| Chemical Formula | C4H6 | C8H8 |

| Monomer Type | Diene hydrocarbon | Aromatic hydrocarbon |

| Polymerization | Forms polybutadiene rubber (BR) | Forms polystyrene or copolymers like styrene-butadiene rubber (SBR) |

| Key Application | High resilience tires, impact-resistant plastics | ABS plastics, packaging, SBR for tires |

| Mechanical Properties | Excellent elasticity and abrasion resistance | Good rigidity and chemical resistance |

| Production Source | Steam cracking of hydrocarbons | Catalytic dehydrogenation of ethylbenzene |

| Market Demand | Driven by automotive tire industry | Driven by plastics and rubber sectors |

Introduction to Butadiene and Styrene

Butadiene is a key industrial chemical primarily used as a monomer in the production of synthetic rubber and plastics, known for its high elasticity and durability. Styrene, an aromatic hydrocarbon, serves as a vital monomer for polystyrene production and various copolymers, valued for rigidity and clarity. Both compounds play crucial roles in manufacturing diverse materials ranging from tires to packaging, highlighting their significance in polymer chemistry.

Chemical Structure Comparison

Butadiene is a simple conjugated diene with the molecular formula C4H6, featuring two double bonds in a linear arrangement which allows for polymerization into synthetic rubbers. Styrene, with the molecular formula C8H8, consists of a vinyl group attached to a benzene ring, combining an aromatic structure with an alkene functional group. The presence of the aromatic ring in styrene results in distinct polymerization characteristics and physical properties compared to the purely aliphatic structure of butadiene.

Physical Properties of Butadiene vs Styrene

Butadiene is a colorless gas at room temperature with a boiling point of -4.4degC, while styrene is a colorless liquid with a higher boiling point of 145degC. The density of butadiene is approximately 0.6 g/cm3, significantly lower than styrene's 0.91 g/cm3, reflecting their different physical states. Your selection between butadiene and styrene depends on these physical properties, influencing storage and handling in industrial applications.

Production Methods and Sources

Butadiene is primarily produced through steam cracking of hydrocarbons such as naphtha and gas oil, while styrene is mainly manufactured via the dehydrogenation of ethylbenzene. Butadiene sources include petrochemical refining and by-products from catalytic cracking, whereas styrene production depends heavily on ethylbenzene derived from benzene and ethylene feedstocks. Understanding these production methods enables you to evaluate supply chain reliability and raw material costs for polymer manufacturing.

Industrial Applications

Butadiene is primarily used in the production of synthetic rubber, including styrene-butadiene rubber (SBR) and polybutadiene, which are essential for manufacturing tires, automotive parts, and footwear. Styrene serves as a key monomer in producing polystyrene, ABS (acrylonitrile butadiene styrene), and various resins used in packaging, insulation, and consumer goods. The combination of butadiene and styrene enhances material properties, making them vital in industries such as automotive, construction, and electronics.

Key Differences in Handling and Storage

Butadiene requires storage at low temperatures and high pressures due to its gaseous state at ambient conditions, demanding specialized pressurized containers and continuous cooling systems. Styrene, being a liquid monomer, is stored at moderate temperatures with inhibitors to prevent polymerization, necessitating airtight containers to minimize exposure to oxygen and light. Handling butadiene involves stringent safety protocols to avoid leaks and explosive mixtures, while styrene requires precautions against skin contact and inhalation due to its irritant properties.

Environmental Impact and Safety Concerns

Butadiene is a volatile organic compound with a higher toxicity profile, posing significant health risks such as respiratory issues and carcinogenic effects, while styrene primarily causes irritation and has potential neurotoxic impacts. Both chemicals contribute to air pollution, but butadiene's role as a known carcinogen and its higher reactivity with atmospheric components lead to greater environmental hazards. Proper handling and stringent exposure controls are critical for butadiene due to its flammability and toxicity, whereas styrene requires monitoring to prevent chronic health effects and environmental contamination.

Market Demand and Economic Factors

Butadiene and styrene exhibit distinct market demand driven by their applications in synthetic rubber and polystyrene production, respectively, with growing automotive and packaging industries fueling demand for butadiene-based products. Economic factors such as raw material availability, crude oil prices, and geopolitical stability significantly influence the production costs and pricing trends of both chemicals. The rising emphasis on sustainability and bio-based feedstocks is shaping investment and growth opportunities within the butadiene and styrene markets.

Health Risks and Regulatory Guidelines

Butadiene exposure is linked to increased cancer risk and respiratory issues, with OSHA setting a permissible exposure limit (PEL) of 1 ppm over an 8-hour workday. Styrene is associated with effects on the central nervous system and possible carcinogenicity, with the ACGIH recommending a threshold limit value (TLV) of 20 ppm as a time-weighted average. Regulatory agencies enforce strict monitoring and control measures for both chemicals to minimize occupational hazards and ensure industrial safety compliance.

Future Trends in Butadiene and Styrene Usage

Rising demand for sustainable materials is driving innovation in biobased butadiene and styrene production, targeting reduced carbon footprints and enhanced recyclability. Growth in automotive and construction industries fuels increased usage of butadiene-based synthetic rubbers and styrene-derived polystyrene for lightweight, durable components. Advancements in catalyst technology and feedstock diversification are expected to improve production efficiency and lower costs, supporting the expansion of both butadiene and styrene markets globally.

Butadiene vs Styrene Infographic

libmatt.com

libmatt.com