Rubber tracks provide superior shock absorption and flexibility, making them ideal for rough terrains and minimizing ground damage, while polyurethane tracks offer enhanced durability, chemical resistance, and a smoother ride on hard surfaces, extending the lifespan of your machinery. Choosing between rubber track vs polyurethane track depends on your operational environment and specific performance needs.

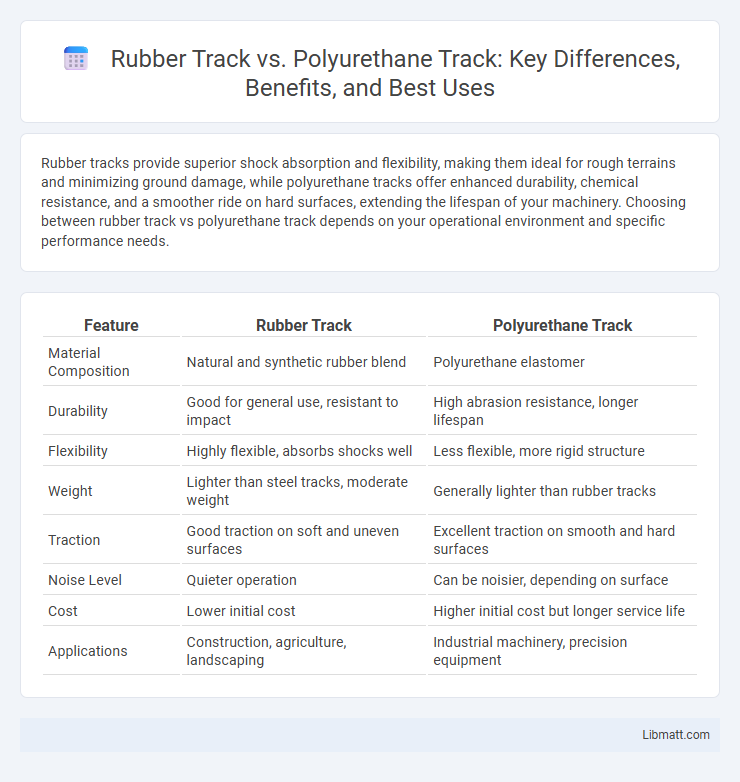

Table of Comparison

| Feature | Rubber Track | Polyurethane Track |

|---|---|---|

| Material Composition | Natural and synthetic rubber blend | Polyurethane elastomer |

| Durability | Good for general use, resistant to impact | High abrasion resistance, longer lifespan |

| Flexibility | Highly flexible, absorbs shocks well | Less flexible, more rigid structure |

| Weight | Lighter than steel tracks, moderate weight | Generally lighter than rubber tracks |

| Traction | Good traction on soft and uneven surfaces | Excellent traction on smooth and hard surfaces |

| Noise Level | Quieter operation | Can be noisier, depending on surface |

| Cost | Lower initial cost | Higher initial cost but longer service life |

| Applications | Construction, agriculture, landscaping | Industrial machinery, precision equipment |

Introduction to Track Materials

Rubber tracks offer enhanced flexibility and cushioning, making them ideal for rough or uneven terrain, while polyurethane tracks provide superior durability and resistance to abrasion in harsh environments. Your choice depends on operational needs, with rubber tracks excelling in traction and vibration reduction, and polyurethane tracks excelling in longevity and chemical resistance. Both materials influence machine performance, maintenance costs, and overall efficiency in construction and agricultural applications.

Overview of Rubber Track Systems

Rubber track systems consist of flexible, durable rubber reinforced with steel cables, designed to enhance traction and reduce ground pressure on construction and agricultural machinery. Known for their shock absorption and noise reduction, rubber tracks improve machine stability on various terrains while minimizing damage to sensitive surfaces. Their lightweight construction also allows for easier transport and installation compared to rigid track alternatives like polyurethane tracks.

Overview of Polyurethane Track Systems

Polyurethane track systems offer exceptional durability and resistance to abrasion, making them ideal for smooth or paved surfaces where wear reduction is critical. These tracks deliver quieter operation and increased traction due to their elastic properties, enhancing overall machine performance on urban or indoor sites. Your choice of polyurethane tracks can improve efficiency and reduce maintenance costs compared to traditional rubber tracks, especially in environments demanding high precision and minimal surface damage.

Durability: Rubber vs Polyurethane

Rubber tracks offer excellent flexibility and ground traction, making them ideal for uneven terrain but tend to wear faster under heavy loads or abrasive surfaces. Polyurethane tracks provide superior durability with enhanced resistance to cuts, abrasions, and chemicals, resulting in a longer lifespan for equipment operating in harsh industrial environments. Choosing polyurethane tracks can improve your machinery's performance and reduce downtime due to track replacements.

Traction and Performance Differences

Rubber tracks offer superior traction on rough, uneven terrains due to their flexibility and natural grip, making them ideal for off-road and construction applications. Polyurethane tracks provide enhanced performance on smooth surfaces, delivering better resistance to wear and chemical exposure, which benefits indoor and industrial environments. The choice between rubber and polyurethane tracks depends on the specific traction needs and operational conditions, with rubber excelling in rugged settings and polyurethane in controlled, abrasive-resistant contexts.

Maintenance Requirements and Longevity

Rubber tracks require regular inspection for cuts, tears, and debris buildup to maintain optimal performance, while polyurethane tracks offer increased resistance to abrasion and chemical damage, reducing maintenance frequency. The lifespan of rubber tracks typically ranges from 1,200 to 1,800 hours depending on operating conditions, whereas polyurethane tracks can last significantly longer, often exceeding 2,500 hours due to their durability. Choosing the right track for your equipment impacts both maintenance costs and operational efficiency over time.

Cost Comparison: Rubber vs Polyurethane

Rubber tracks generally cost less upfront compared to polyurethane tracks, making them a more budget-friendly choice for short-term use or lighter applications. Polyurethane tracks, while more expensive initially due to their durability and resistance to wear, offer lower maintenance costs and a longer lifespan, providing better overall value in heavy-duty or long-term operations. Your decision on track type should consider both the initial expenditure and the total cost of ownership to optimize investment efficiency.

Environmental Impact and Sustainability

Rubber tracks offer greater environmental sustainability due to their biodegradability and lower production energy requirements compared to polyurethane tracks, which rely on petroleum-based materials and exhibit limited recyclability. The manufacturing of rubber tracks generates fewer greenhouse gas emissions and harmful pollutants, making them a greener choice for off-road machinery. Choosing rubber tracks supports reduced environmental footprint while maintaining durability and performance.

Application Suitability: Choosing the Right Track

Rubber tracks excel in rough terrain and heavy-duty construction due to their flexibility, shock absorption, and abrasion resistance, making them ideal for excavators and skid steers. Polyurethane tracks offer superior durability and chemical resistance, suited for indoor or smooth surface applications like floor scrubbers and automated guided vehicles (AGVs). Selecting the right track depends on operational environment, load requirements, and surface conditions to maximize performance and lifespan.

Conclusion: Which Track is Best for Your Needs

Rubber tracks offer superior traction and reduced ground damage, making them ideal for soft or uneven terrains, while polyurethane tracks provide enhanced durability and resistance to chemicals and abrasions, better suited for concrete or indoor environments. Your choice depends on the operational conditions and performance priorities, balancing factors like surface type, load capacity, and lifespan. Consider the specific demands of your equipment and worksite to determine which track maximizes efficiency and cost-effectiveness.

Rubber Track vs Polyurethane Track Infographic

libmatt.com

libmatt.com