Silane and titanate coupling agents enhance adhesion by chemically bonding inorganic surfaces to organic materials in composites and coatings. Your choice depends on the substrate and application, as silanes are typically used for glass and minerals, while titanates work well with metals and plastics.

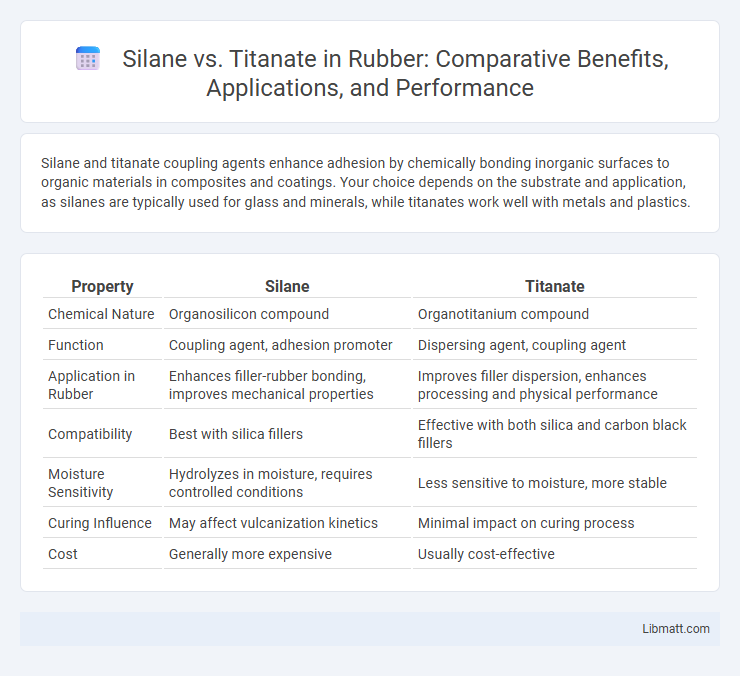

Table of Comparison

| Property | Silane | Titanate |

|---|---|---|

| Chemical Nature | Organosilicon compound | Organotitanium compound |

| Function | Coupling agent, adhesion promoter | Dispersing agent, coupling agent |

| Application in Rubber | Enhances filler-rubber bonding, improves mechanical properties | Improves filler dispersion, enhances processing and physical performance |

| Compatibility | Best with silica fillers | Effective with both silica and carbon black fillers |

| Moisture Sensitivity | Hydrolyzes in moisture, requires controlled conditions | Less sensitive to moisture, more stable |

| Curing Influence | May affect vulcanization kinetics | Minimal impact on curing process |

| Cost | Generally more expensive | Usually cost-effective |

Introduction to Silane and Titanate

Silane and titanate are widely used coupling agents that improve adhesion between organic polymers and inorganic substrates, enhancing composite material performance. Silanes contain silicon atoms and form strong chemical bonds through hydrolysis and condensation reactions, making them ideal for glass, metal, and mineral surface treatments. Titanates, based on titanium atoms, provide unique surface chemistry that promotes compatibility in plastics, coatings, and adhesives by improving dispersion and mechanical properties.

Chemical Structure Comparison

Silane molecules consist of a central silicon atom bonded to organic functional groups and hydrolyzable alkoxy groups, enabling strong covalent bonding with both inorganic surfaces and organic polymers. Titanates feature a titanium center bonded to alkoxy ligands and organofunctional groups, providing versatile reactivity but generally forming coordination rather than covalent bonds with substrates. The distinct chemical structures influence their effectiveness as coupling agents, with silanes promoting durable adhesion through silicon-oxygen networks, while titanates excel in enhancing surface compatibility via reactive titanium centers.

Mechanisms of Surface Modification

Silane modifies surfaces through the formation of strong covalent bonds between its alkoxy groups and hydroxyl groups on the substrate, creating a durable and hydrophobic layer. Titanate acts as a coupling agent by coordinating with surface hydroxyl groups and forming organotitanate complexes that enhance interfacial adhesion and dispersion in composite materials. Understanding these distinct mechanisms helps optimize your choice of surface modifier for specific applications in coatings, adhesives, and polymers.

Applications in Industry

Silane is widely used in the coatings, adhesives, and sealants industries to enhance adhesion, durability, and corrosion resistance. Titanate finds extensive applications in plastics and rubber manufacturing as a coupling agent and catalyst, improving flexibility and processing efficiency. Both compounds play critical roles in the automotive, construction, and electronics sectors by optimizing material performance and longevity.

Adhesion Enhancement Capabilities

Silane offers superior adhesion enhancement by forming strong chemical bonds between organic polymers and inorganic surfaces through its bifunctional structure. Titanate acts as a versatile coupling agent that improves adhesion by promoting compatibility between diverse substrates, especially in flexible and dynamic applications. Your choice should consider specific material compatibility and environmental conditions to maximize adhesive performance.

Thermal and Chemical Stability

Silane coupling agents exhibit excellent thermal stability, resisting degradation at temperatures up to 400degC, while titanate-based coupling agents typically maintain stability only up to around 250degC. Chemically, silanes form strong covalent bonds with silica and organic substrates, offering superior resistance to hydrolysis and chemical attack compared to titanates, which are more prone to hydrolytic degradation. Understanding these differences helps you select the optimal coupling agent for applications requiring enhanced durability under harsh thermal and chemical environments.

Compatibility with Polymers and Fillers

Silane coupling agents exhibit high compatibility with a wide range of polymers such as polyethylene, polypropylene, and epoxy resins, enhancing adhesion between fillers like glass fibers and silica and the polymer matrix. Titanate coupling agents, favored for their superior bonding with inorganic fillers including calcium carbonate and talc, also improve dispersion in polymers like polyurethane and elastomers. Your choice depends on the specific polymer-filler system, as silanes excel in siliceous fillers and titanates in non-siliceous mineral fillers.

Environmental Impact and Safety

Silane and titanate coupling agents differ significantly in environmental impact and safety profiles, with silanes generally exhibiting lower toxicity and biodegradability, making them more eco-friendly. Titanates, while effective in enhancing adhesion and compatibility in composites, pose higher risks due to their potential to release titanium compounds that can be toxic to aquatic life. Your choice between silane and titanate should consider these environmental and safety factors alongside performance requirements for sustainable materials management.

Cost and Availability

Silane coupling agents generally offer a lower cost and wider availability compared to titanates, making them a popular choice for various industrial applications. Titanates tend to be more expensive due to their specialized chemical properties and are less commonly stocked by suppliers, which can affect lead times. Understanding the cost and availability differences between silane and titanate helps you make an informed selection for your specific material compatibility and budget requirements.

Choosing Between Silane and Titanate

Choosing between silane and titanate depends on the specific application and material compatibility. Silane coupling agents are ideal for enhancing adhesion between organic and inorganic materials, particularly in rubber and composite industries. Your selection should consider factors like bond strength, moisture resistance, and the type of substrate to ensure optimal performance.

Silane vs Titanate Infographic

libmatt.com

libmatt.com