Thermoplastic rubber combines the elastic properties of traditional rubber with the recyclability and easy processing of thermoplastics, making it ideal for applications requiring flexibility and durability. Elastomers, known for their high elasticity and resilience, are typically more resistant to heat and chemicals but lack the recyclability of thermoplastic rubber, which could limit your material choices based on environmental considerations.

Table of Comparison

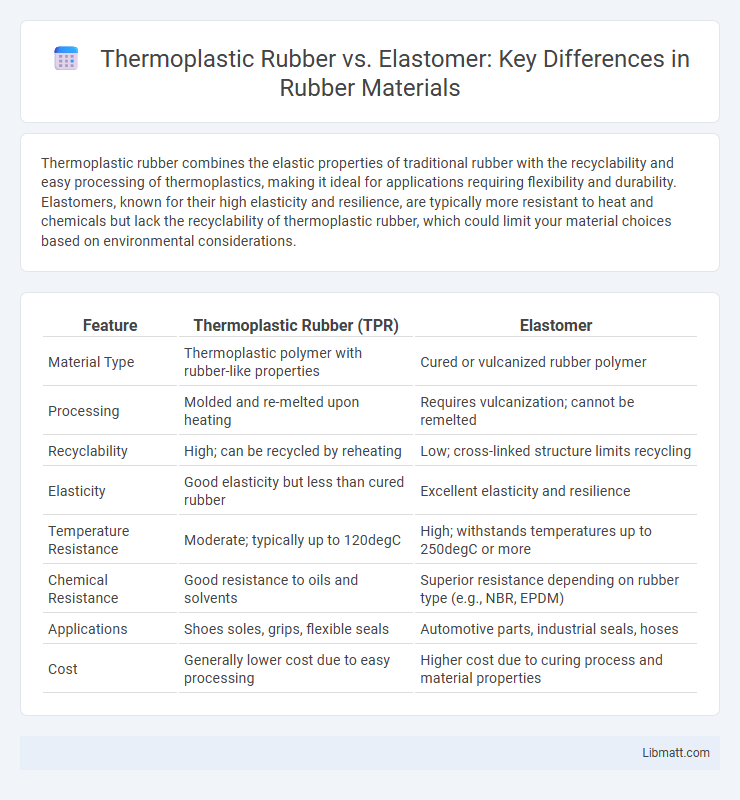

| Feature | Thermoplastic Rubber (TPR) | Elastomer |

|---|---|---|

| Material Type | Thermoplastic polymer with rubber-like properties | Cured or vulcanized rubber polymer |

| Processing | Molded and re-melted upon heating | Requires vulcanization; cannot be remelted |

| Recyclability | High; can be recycled by reheating | Low; cross-linked structure limits recycling |

| Elasticity | Good elasticity but less than cured rubber | Excellent elasticity and resilience |

| Temperature Resistance | Moderate; typically up to 120degC | High; withstands temperatures up to 250degC or more |

| Chemical Resistance | Good resistance to oils and solvents | Superior resistance depending on rubber type (e.g., NBR, EPDM) |

| Applications | Shoes soles, grips, flexible seals | Automotive parts, industrial seals, hoses |

| Cost | Generally lower cost due to easy processing | Higher cost due to curing process and material properties |

Introduction to Thermoplastic Rubber and Elastomers

Thermoplastic rubber (TPR) combines the elastic properties of rubber with the processability of thermoplastics, making it ideal for applications requiring flexibility and durability. Elastomers are a broad class of polymers characterized by their highly elastic behavior, capable of returning to their original shape after deformation. Understanding the differences between TPR and traditional elastomers can help you select the best material for products needing both flexibility and efficient manufacturing.

Key Definitions: Thermoplastic Rubber vs Elastomer

Thermoplastic rubber (TPR) combines the elastic properties of rubber with the recyclability of thermoplastics, allowing it to be melted and reshaped multiple times without significant degradation. Elastomers are polymers characterized by their ability to return to their original shape after deformation, displaying high elasticity but typically requiring vulcanization to set their form permanently. Understanding the differences in processing and recyclability between thermoplastic rubber and elastomers is essential for selecting the right material for Your flexible product design.

Composition and Chemical Structure

Thermoplastic rubber (TPR) is a blend of thermoplastics and elastomers, combining the flexibility of rubber with the processability of plastics, characterized by a block copolymer structure with hard and soft segments. Elastomers consist primarily of cross-linked polymer chains, giving them high elasticity and resilience due to their amorphous and loosely bonded chemical structure. Your choice between TPR and elastomer depends on the desired balance of flexibility, durability, and ease of manufacturing in applications.

Physical and Mechanical Properties

Thermoplastic rubber combines the elasticity of elastomers with the processability of plastics, offering excellent flexibility, durability, and impact resistance, while elastomers provide superior elasticity and resilience under dynamic stress. Thermoplastic rubber typically exhibits higher tensile strength and better abrasion resistance compared to traditional elastomers, which excel in maintaining elasticity over a wide temperature range. Your choice between the two depends on whether you prioritize ease of manufacturing and recyclability or maximum elasticity and long-term mechanical performance.

Manufacturing Processes Compared

Thermoplastic rubber (TPR) is manufactured using injection molding and extrusion processes, allowing for efficient recycling and faster production cycles. Elastomers, such as vulcanized rubber, undergo a curing process involving heat and sulfur or other cross-linking agents, resulting in permanent elastic properties that limit recyclability. Your choice between TPR and elastomer depends on manufacturing speed, cost-efficiency, and end-use product flexibility requirements.

Applications in Various Industries

Thermoplastic rubber (TPR) is widely used in automotive parts, medical devices, and consumer goods due to its flexibility, durability, and recyclability. Elastomers find applications in aerospace seals, industrial gaskets, and footwear because of their excellent elasticity and resistance to extreme temperatures. Understanding the differences can help you choose the right material for your industry-specific requirements.

Performance in Extreme Conditions

Thermoplastic rubber (TPR) exhibits excellent flexibility and impact resistance at low temperatures but may soften at high heat, limiting its use in extreme thermal environments. Elastomers, such as silicone and fluorocarbon, maintain superior elasticity and chemical resistance under both high temperatures and severe weather conditions, making them ideal for demanding industrial applications. Performance in extreme environments strongly favors elastomers due to their molecular structure that preserves mechanical properties despite temperature fluctuations.

Cost and Environmental Impact

Thermoplastic rubber (TPR) generally offers a lower cost advantage over traditional elastomers due to its recyclability and ease of processing, which reduces manufacturing expenses. Elastomers often require more energy-intensive curing processes and generate more waste, contributing to a higher environmental footprint. You can optimize your product's sustainability and budget by choosing TPR for applications needing cost efficiency and eco-friendly materials.

Advantages and Limitations

Thermoplastic rubber (TPR) offers the advantage of easy processing and recyclability, providing flexibility combined with the ability to be molded repeatedly without chemical vulcanization. Elastomers excel in superior elasticity, resistance to extreme temperatures, and enhanced durability in demanding applications, though they typically require vulcanization and are less recyclable. While TPR is suitable for cost-effective, lightweight products with moderate performance requirements, elastomers are preferred for heavy-duty uses where long-lasting elasticity and toughness are crucial despite higher production complexity.

Choosing Between Thermoplastic Rubber and Elastomer

Thermoplastic rubber offers the advantage of easy processing and recyclability due to its thermoplastic nature, making it suitable for applications requiring flexibility and repetitive molding. Elastomers provide superior elasticity and durability, ideal for high-performance products exposed to extreme conditions and continuous stress. Selecting between the two depends on factors such as application requirements, environmental exposure, cost constraints, and desired mechanical properties.

Thermoplastic Rubber vs Elastomer Infographic

libmatt.com

libmatt.com